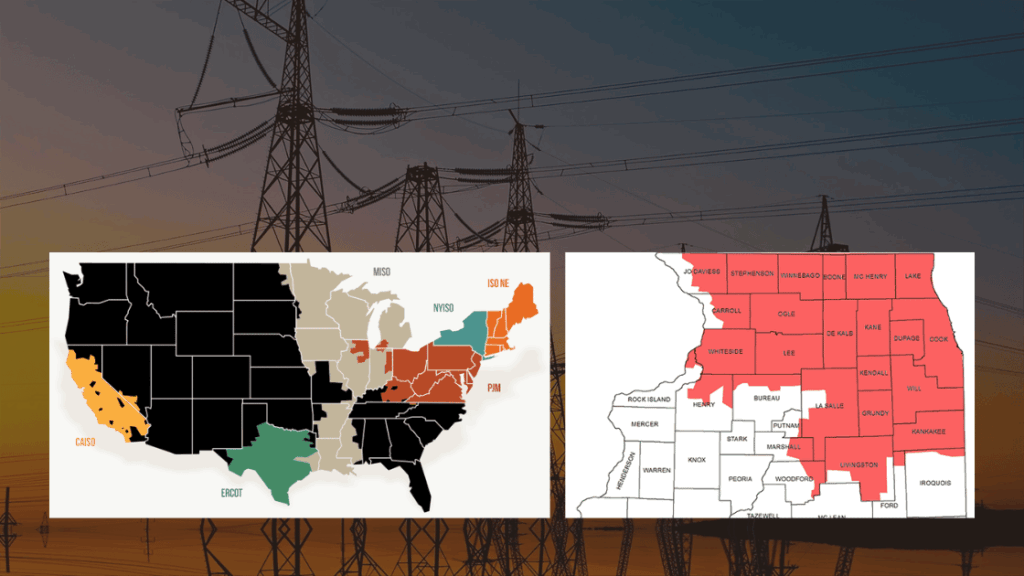

As the Midwest’s power grid evolves to meet growing demand, aging infrastructure, and renewable energy integration, ComEd’s Supplemental Projects provide a roadmap for proactive transmission upgrades. These initiatives, aligned with the PJM M-3 planning process, highlight an urgent need for innovative electrical engineering solutions — and Keentel Engineering is ready to lead the charge.

Why ComEd’s Supplemental Projects Matter

During the March 4, 2025, TEAC Western Committee meeting, ComEd shared critical infrastructure updates across Illinois. The primary drivers behind these projects include:

- Aging and Obsolete Equipment

- Customer Load Growth and Interconnection Demands

- Regional Congestion and Reliability Risks Identified by MISO

At Keentel Engineering, we recognize that expert transmission engineering is essential to delivering safe, reliable, and future-ready power systems — and we are proud to serve as a trusted partner in this transformation.

Project Highlights & Keentel’s Engineering Contributions

Dresden 345kV Breaker Replacement (ComEd-2024-017)

- Challenge: Oil circuit breakers from 1968 are obsolete and unmaintainable.

- Keentel’s Role:

- Condition assessment

- SF₆ breaker specification

- Procurement support

- Field commissioning assistance

- Upgrade Details:

- Existing: 1600A, 40kA breakers

- Replacement: 3000A, 63kA SF₆ breakers

- Value Delivered: Increased system capacity, reduced maintenance, enhanced reliability.

Plano Area Transmission for Large Load Interconnection (ComEd-2024-015)

- Challenge: A new customer requires up to 600 MW of load capacity by 2029.

- Keentel’s Role:

- 345kV line extensions

- Eldamain Substation design

- Protection, control, and interconnection studies

- Regulatory and permitting support

- Scope:

- New 345kV ring bus expandable to breaker-and-a-half.

- Radial leads connecting to customer facilities.

MISO LRTP Tranche 2.1 Integration (ComEd-2024-023)

- Challenge: Long-range transmission planning (LRTP) from MISO demands 765kV grid reinforcements.

- Key Upgrades:

- Expansion of Collins 765kV substation

- Two new 765kV transmission lines connecting MISO

- 300 MVAR reactors installation

- Woodford County substation development

- Total Estimated Investment: $874.2 million

- Keentel’s Expertise:

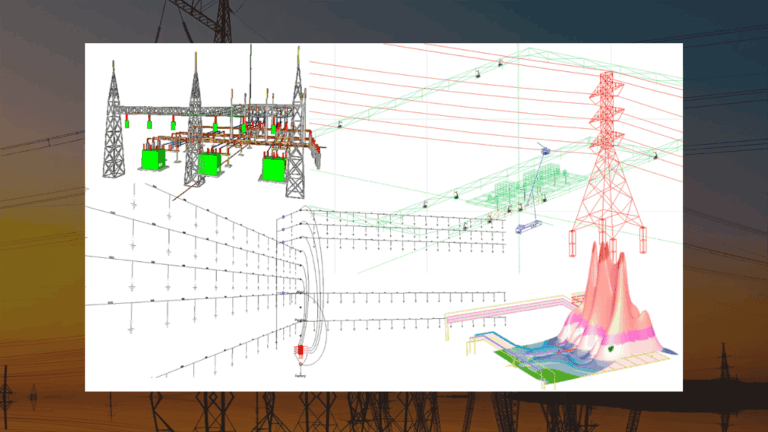

- Conceptual and detailed 765kV/345kV system design

- Grounding studies, bus layouts, and surge protection

- Full NERC, PJM, and MISO compliance

Keentel Engineering: Trusted Partner for Transmission Excellence

With 30+ years of experience in high-voltage (HV) and extra-high voltage (EHV) engineering, Keentel Engineering is a reliable partner for utilities and developers in the PJM and ComEd territories.

Our Core Transmission Services Include:

- Transmission Line Design (345kV–765kV)

- Substation Design (Ring Bus, Breaker-and-a-Half, GIS)

- Relay Protection and Control System Engineering

- Grid Interconnection Studies

- Owner’s Engineering and QA/QC Oversight

- Regulatory Filing Support (PJM, FERC, NERC)

Explore more about our Substation Design Services.

Let’s Power the Future Together

As ComEd modernizes its transmission network alongside PJM and MISO, the need for specialized, forward-thinking engineering services is greater than ever.

Keentel Engineering stands ready to ensure your grid projects are safe, scalable, and built for the future.

📞 Call us at 813-389-7871

🌐 Visit to start your project with our expert team!

Frequently Asked Questions – ComEd & PJM Transmission Engineering

General & Strategic

1. What role does Keentel Engineering play in ComEd or PJM transmission projects?

Keentel delivers design, relay protection, system studies, interconnection support, and regulatory compliance for HV/EHV projects.

2. How does Keentel assist utilities with aging infrastructure replacements?

We assess aging assets, recommend SF₆ upgrades, and manage procurement and commissioning phases.

3. Is Keentel experienced with the PJM M-3 planning process?

Yes, we actively participate in PJM’s M-3 process, including need assessments, solution development, and Do-No-Harm (DNH) analyses.

4. Can Keentel design and route transmission lines?

Absolutely. We offer full routing analysis, conductor selection, and structure design compliant with PJM and NESC standards.

5. Can you support high-voltage substation expansions like Collins 765kV?

Yes. We provide bus layouts, equipment specifications, grounding design, and grid operator coordination.

Technical Engineering

6. Why transition from oil to SF₆ circuit breakers?

SF₆ breakers offer higher interrupting capacity, greater reliability, and significantly lower maintenance needs.

7. How does Keentel ensure NERC relay protection compliance?

Through protection and coordination studies aligned with NERC PRC standards and PJM technical requirements.

8. Does Keentel handle breaker-and-a-half bus designs?

Yes, our substation engineers have extensive experience with breaker-and-a-half and GIS designs.

9. Does Keentel work with 765kV transmission projects?

Absolutely. We support 765kV design, grounding, electromagnetic transient analysis, and surge protection.

10. How does Keentel manage reactor and capacitor installations?

We size, design layouts, conduct transient analysis, and specify switching equipment for reactors and capacitors.

Compliance & Studies

11. How does Keentel help with MISO Tranche 2.1 compliance?

We design systems aligned with MISO LRTP and Appendix A project guidelines.

12. What studies are needed for PJM RTEP integration?

Steady-state, short-circuit, transient stability, and power flow studies for successful interconnection approval.

13. Does Keentel perform grounding studies?

Yes. Our team conducts IEEE Std 80 grounding studies for substations and transmission lines.

14. What is Do-No-Harm (DNH) analysis?

An evaluation to ensure a new transmission project doesn’t degrade system performance, required by PJM.

15. How does Keentel help customer interconnections like Plano’s 600MW project?

We support POI selection, transmission protection design, and perform System Impact Studies (SIS).

Delivery & Operations

16. How fast can Keentel mobilize?

We can mobilize engineers quickly for feasibility, conceptual design, or detailed engineering stages.

17. Does Keentel act as Owner’s Engineer?

Yes, offering independent design reviews, QA/QC verification, and construction support.

18. How does Keentel control project costs?

We provide detailed, realistic cost estimates early and recommend value-engineering strategies to reduce CAPEX.

19. What design tools does Keentel use?

PLS-CADD, ETAP, PSCAD, PSSE, ASPEN OneLiner, AutoCAD, and CYME.

20. Is Keentel available for long-term PJM and ComEd partnerships?

Absolutely. We specialize in multi-phase support — from permitting to design to commissioning.