Utility Scale Wind Farm Engineering Services

Keentel Engineering offers trusted, expert-driven wind engineering services for utility-scale wind energy projects across the U.S. Our electrical engineering solutions are tailored for large-scale wind farms—supporting everything from initial design to grid connection, testing, and performance optimization.

Whether you’re building a new wind farm or upgrading an existing facility, we deliver engineering excellence with a focus on efficiency, compliance, and reliability.

Why Choose Us

At Keentel Engineering, we take pride in being the go-to engineering firm for power and utility system planning, design, control, and analysis. Some of the many attributes of our company that set us apart are:

Client-Focused Work Approach

Our team works cohesively on every project and with every client. We first develop a solid understanding of your project goals, requirements, and needs. From concept to commissioning, we assist you in every step.

30 Years of Experience

We have over three decades of experience in design and interconnection. Rest assured, we have the knowledge, understanding, and expertise to handle and execute all types of projects with sheer perfection and superior workmanship.

Quality with Innovation

At Keentel Engineering, we have established our stellar market reputation on quality, work ethics, and innovation.

Attention-to-Detail

We work on every project with laser focus and attention to detail. This enables our team to deliver desired results with complete satisfaction.

Let's Discuss How to Optimize Your Next Project

Submit

We will get back to you as soon as possible.

Please try again later.

Our End-to-End Electrical Engineering Services for Wind Farms

Keentel Engineering offers complete electrical engineering support for utility-scale wind farms—designed to meet your project’s full lifecycle needs. From feasibility to optimization, our services are built for performance, compliance, and long-term value.

POI Interconnection Engineering Support

Our skilled and knowledgeable engineering team has a rich history in designing, developing and commissioning various substation and interconnection engineering support projects.

Feasibility Studies and Site Assessments

Before design begins, we conduct in-depth feasibility studies and site assessments to determine the viability of your wind project. This includes evaluating terrain characteristics, elevation changes, proximity to transmission infrastructure, and potential environmental constraints. In collaboration with your resource assessment team, we support the deployment of LiDAR, SODAR, or met towers to gather accurate wind data. These insights guide turbine placement, grid connectivity planning, and project financing confidence—ensuring that your site supports long-term energy production and return on investment.

Electrical System Design

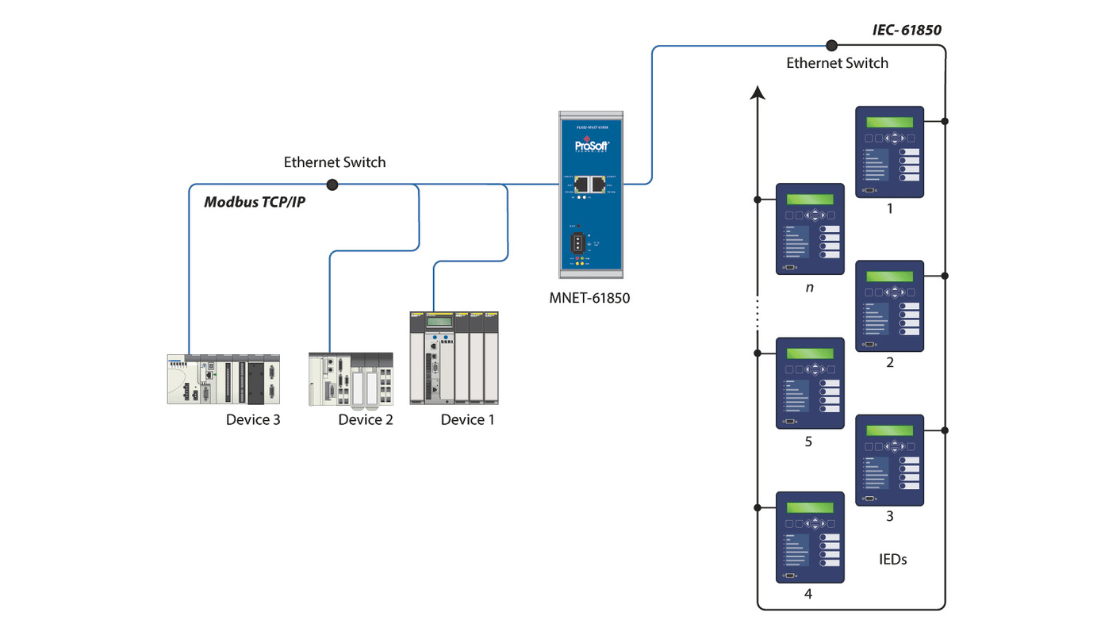

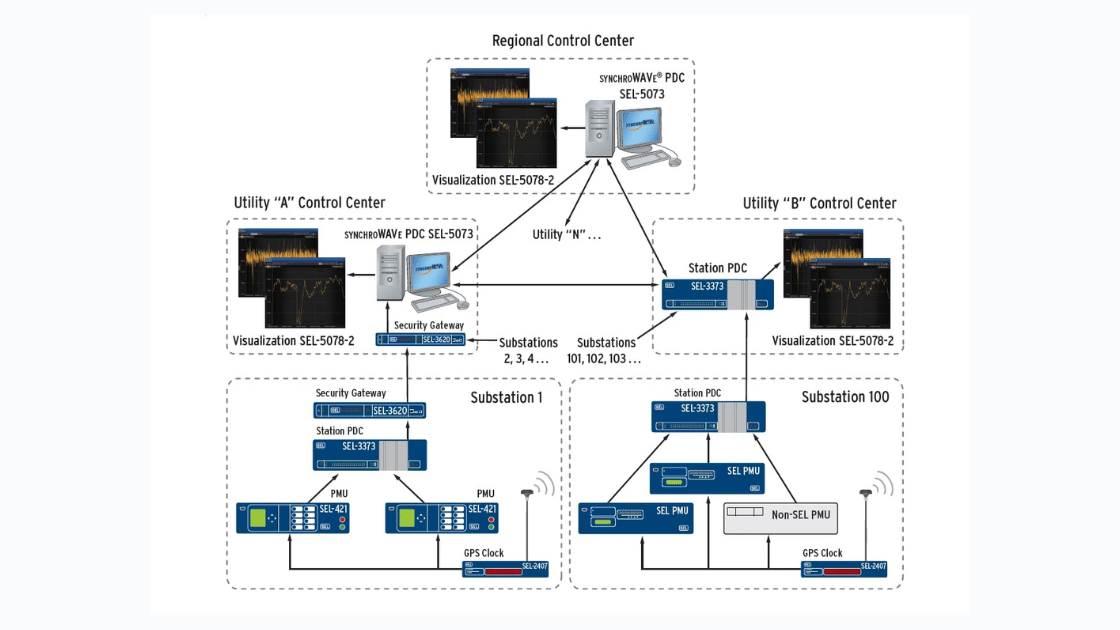

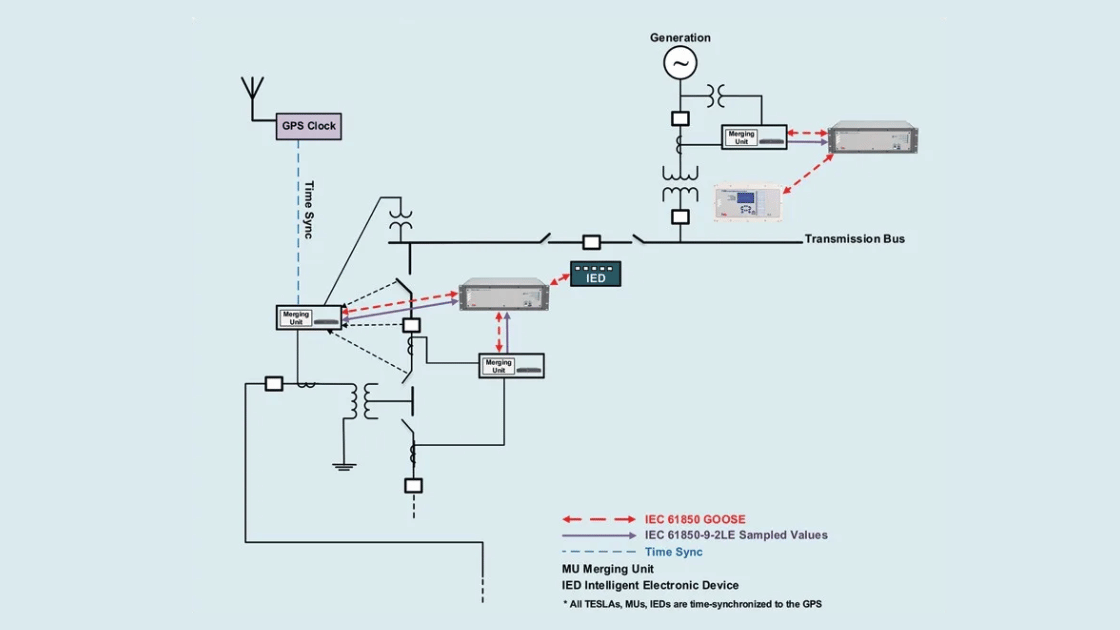

Keentel provides full electrical system design services for utility-scale wind farms, covering both medium- and high-voltage systems. Our engineers develop complete layouts for collector systems, transformer configurations, grounding systems, and substation integration. We ensure each system is engineered to meet utility requirements, FERC standards, and ISO interconnection protocols. This also includes SCADA network design, relay protection schemes, and one-line diagrams that support both performance and regulatory complianc

Equipment Sourcing and Specification

Our team assists in selecting and specifying key electrical components required for grid-scale wind energy systems. This includes step-up transformers, switchgear, power cabling, reactive compensation equipment, and control hardware. Each selection is made to balance reliability, long-term maintainability, and performance efficiency. We also coordinate delivery timelines and vendor compatibility to streamline procurement and avoid construction delays.

POI Interconnection Engineering Support

Our skilled and knowledgeable engineering team has a rich history in designing, developing and commissioning various substation and interconnection engineering support projects.

Installation and

Commissioning

Keentel engineers oversee the electrical aspects of the installation and commissioning process. We work closely with field teams and contractors to ensure that equipment is installed according to design specifications, tested thoroughly, and prepared for grid connection. Our commissioning process includes functional testing, protection coordination validation, SCADA configuration, and utility inspections. These steps ensure a safe, efficient, and code-compliant handoff to operations.

Grid Connection and

Interfacing

Grid interconnection is a critical part of every wind project. Our team manages the engineering and documentation required for POI (Point of Interconnection) approvals, ensuring seamless interfacing between your wind farm and the local transmission network. We provide support for utility and ISO submission packages, coordinate substation integration, and ensure compliance with interconnection agreements and applicable NERC reliability standards.

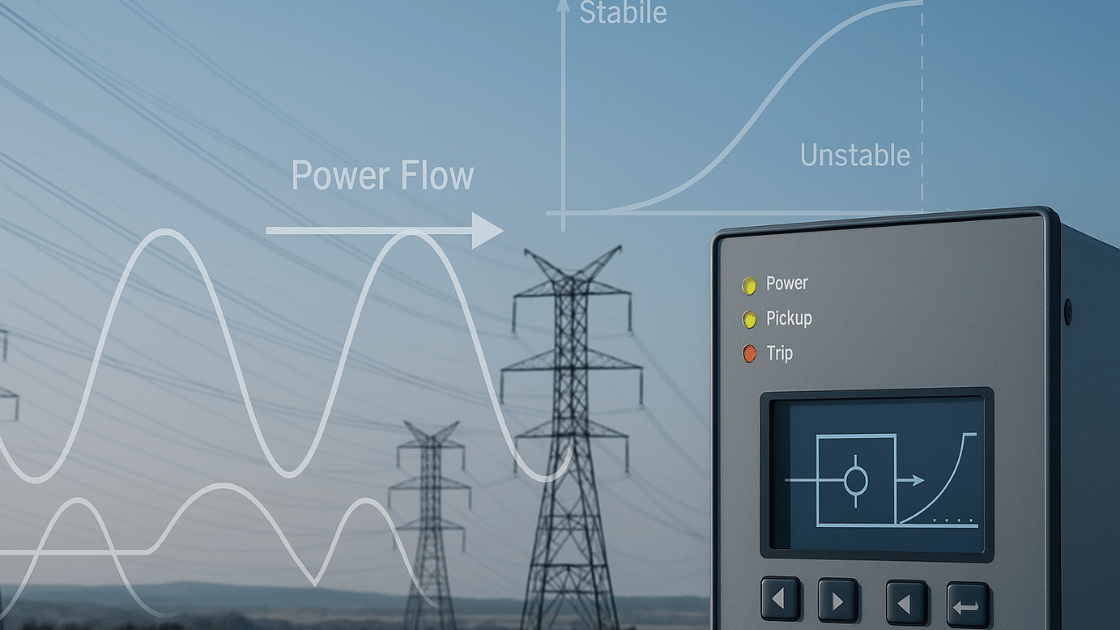

Power Quality and System Stability Analysis

Keentel performs detailed power quality studies and system stability analyses to ensure your wind farm operates without negatively impacting the broader grid. We evaluate voltage regulation, frequency stability, harmonics, and reactive power behavior across all operational conditions. These assessments are especially important for projects participating in capacity markets or located in congested grid zones.

POI Interconnection Engineering Support

Our skilled and knowledgeable engineering team has a rich history in designing, developing and commissioning various substation and interconnection engineering support projects.

Maintenance and

Monitoring

Our engineering team supports your ongoing operations with structured maintenance planning and real-time system monitoring. We help implement SCADA-integrated diagnostics, establish baseline performance thresholds, and support both scheduled and reactive maintenance strategies. Through predictive analytics and historical performance tracking, we help identify emerging issues early, reduce downtime, and maintain high availability.

Performance

Optimization

Beyond initial commissioning, we continually work with owners and operators to enhance performance. We conduct system-wide reviews using live data, assess production losses, and recommend electrical or control system improvements. This may include tuning of reactive power controls, upgrading protection logic, or adjusting SCADA setpoints—all designed to increase energy output, improve power quality, and reduce operational inefficiencies.

Upgrades and

Retrofits

For aging or underperforming assets, we provide upgrade and repowering support. This includes replacing outdated electrical components, integrating modern SCADA platforms, and reconfiguring collector systems to accommodate turbine retrofits. We also assist with engineering packages required for repowering approvals, ensuring your wind farm meets the latest regulatory and performance expectations without major design rework.

Wind Resource Assessment & Site Feasibility

Before a single turbine is selected, we help you determine whether your site is technically viable and financially sustainable.

Keentel supports or coordinates advanced wind resource assessment activities, including:

- LiDAR and SODAR wind speed measurement

- Turbulence and shear analysis at multiple hub heights

- Terrain and topography modeling for turbine placement

- Proximity to substations or transmission lines

- Grid connection feasibility and interconnection study prep

We ensure that each project begins with data-backed decisions, minimizing future delays and optimizing energy output from the start.

Electrical System Design & Grid Interconnection

Keentel Engineering specializes in wind farm electrical design that ensures safe, reliable, and compliant power delivery from turbine to transmission grid.

We provide full-scope electrical engineering for wind energy systems, including:

- Medium- and high-voltage collection system design

- Step-up transformers and grounding system layouts

- Substation and switchgear integration

- SCADA system configuration and grid monitoring points

- Point of Interconnection (POI) application support

- Relay protection and NERC-compliant studies

Our designs align with utility standards, ISO/RTO requirements, and FERC/NERP policies—ensuring your wind farm connects to the grid on time and without costly revisions.

Explore our

Substation Design services.

Installation, Commissioning & Testing

Keentel provides electrical oversight and commissioning support to ensure your wind farm operates safely, efficiently, and in full compliance from day one.

Our installation and commissioning services include:

- Electrical infrastructure deployment (cables, transformers, switchgear)

- Functional testing of power collection systems and substations

- SCADA integration with control centers

- Grid synchronization and POI verification

- Safety and compliance inspections before energization

We coordinate closely with your EPCs and field contractors, providing hands-on engineering guidance throughout the final phases of construction and connection.

Power Quality & System Stability Analysis

Grid-connected wind farms must operate smoothly under changing load and weather conditions. Keentel conducts power quality assessments and system stability studies to ensure uninterrupted, compliant operation.

Our engineering team evaluates:

- Voltage regulation and frequency response behavior

- Harmonics and flicker caused by turbine variability

- Reactive power compensation strategies

- Inertia and low-voltage ride-through (LVRT) capabilities

- Compliance with IEEE 519, 1547, and utility-specific guidelines

Learn more about our

Power System Studies.

Operations, Maintenance & Predictive Monitoring

Long-term reliability is just as critical as initial performance. Keentel provides ongoing electrical maintenance and monitoring solutions tailored for utility-scale wind farms.

Our O&M support includes:

- Preventative and corrective electrical inspections

- Remote SCADA-based performance monitoring

- Fault detection and diagnostics using historical trends

- Predictive maintenance scheduling using sensor data

- Integration of UAV (drone) inspections for overhead infrastructure

We help you reduce downtime, extend asset life, and catch issues before they impact production.

Upgrades, Retrofits & Repowering Strategy

Wind technology evolves rapidly. Whether your project is aging or being expanded, Keentel offers engineering solutions to modernize and maximize your assets.

Our retrofit and repowering support includes:

- Generator and converter upgrades

- Blade, tower, or controller replacements

- SCADA and protection system modernization

- Collector system reconfiguration for new capacity

- Coordination with ISOs and utilities on repowering approvals

Explore our

Utility-Scale Battery Storage options for hybrid wind+BESS solutions.

NERC Compliance & Regulatory Support

Utility-scale wind farms must meet evolving grid reliability standards. Keentel Engineering ensures your project is fully aligned with NERC O&P-693, FERC, and ISO guidelines—during both design and operational phases.

We provide compliance engineering for:

- Protection system coordination and PRC studies

- Modeling and simulation support (MOD-026/027)

- Ride-through capability analysis

- Testing and documentation for audit readiness

- Coordination with utilities and RTOs/ISOs

See our full

NERC Compliance service offering.

Why Choose Keentel Engineering?

Expertise

Our team boasts extensive experience in electrical engineering for renewable energy projects, ensuring top-tier results.

Innovation

Proven track record across large-scale solar, wind, and hybrid energy projects

Collaboration

Experts in solar farm engineering services and grid integration

Reliability

Client-first approach with transparent project management

Sustainability

Commitment to sustainable, eco-conscious engineering practices

FAQ for Utility-Scale Solar Farm Engineering Services

1. What is a utility-scale wind farm?

A utility-scale wind farm is a large-scale wind power generation facility designed to produce significant amounts of electricity, typically ranging from tens of megawatts (MW) to hundreds of megawatts. These wind farms are connected to the electrical grid and supply power to utilities, industries, or large consumers. They consist of multiple wind turbines, substations, and electrical infrastructure, spread over large land areas.

2. What services do you offer for utility-scale wind farm engineering?

Our Utility-Scale Wind Farm Engineering Services include:

- Site Assessment & Feasibility Studies: Assessing wind resource availability, land conditions, and environmental factors for optimal site selection.

- Wind Resource Assessment: Performing wind measurements and analyzing historical wind data to determine the potential energy output.

- Turbine Layout & Design: Designing optimal turbine layouts to maximize energy capture while minimizing wake effects, noise, and land use.

- Electrical System Design: Designing the electrical systems for power generation, transmission, and grid integration, including substations, cabling, and transformers.

- Grid Integration & Interconnection Studies: Performing power flow, fault, and stability studies to ensure seamless integration with the electrical grid.

- Structural and Civil Engineering: Designing foundations, roads, and other infrastructure needed for turbine installation and maintenance.

- Permitting & Regulatory Compliance: Ensuring compliance with local, state, and federal regulations, including environmental and safety standards.

- Construction Supervision & Project Management: Overseeing construction activities to ensure timely, cost-effective, and safe implementation.

- Commissioning & Testing: Verifying that all systems are operational and meet performance specifications.

- Ongoing Operation & Maintenance Support: Providing technical support for the continued operation and maintenance of the wind farm.

3. Construction Supervision & Project Management: Overseeing construction activities to ensure timely, cost-effective, and safe implementation.

Engineering is crucial for the success of a utility-scale wind farm because it ensures the project is designed for maximum efficiency, reliability, and safety. Proper engineering helps optimize turbine placement, integrate the system with the grid, minimize environmental impacts, and ensure that the farm operates within regulatory guidelines. Well-engineered systems reduce downtime, extend the life of equipment, and maximize energy production.

4. What factors are considered during the site assessment for a utility-scale wind farm?

Key factors considered during a site assessment include:

- Wind Resource Availability: Measured using meteorological data and on-site wind measurements to determine the expected energy generation.

- Topography and Land Conditions: Evaluating land features, accessibility, and the suitability for turbine installation and infrastructure.

- Environmental Impact: Assessing potential environmental effects, including wildlife impact, noise, and visual concerns.

- Proximity to Transmission Lines: Ensuring that the site is near existing or planned transmission infrastructure for grid connection.

- Regulatory and Zoning Requirements: Reviewing local and regional zoning laws, permitting processes, and environmental regulations.

- Grid Integration Feasibility: Analyzing the capacity and readiness of the grid to accommodate additional wind energy.

5. What is involved in the wind resource assessment for a utility-scale wind farm?

A wind resource assessment involves collecting and analyzing wind data from meteorological towers, remote sensing devices (such as LIDAR or SODAR), and historical wind speed data. We assess factors like:

- Average wind speeds and direction at different heights.

- Wind variability over time to determine consistency.

- Energy production estimates based on the expected wind conditions at the site.

This assessment helps to determine the number and type of turbines required to optimize energy generation and ensure the financial viability of the project.

6. How is the electrical design of a utility-scale wind farm carried out?

The electrical design includes several key components:

- Turbine Connection: Ensuring that each turbine is connected to the grid through appropriate electrical infrastructure, such as cabling, transformers, and substations.

- Substation Design: Designing substations that step up the voltage from turbine generators to transmission-level voltages for grid integration.

- Power Distribution: Ensuring safe and efficient distribution of power from turbines to substations, including wiring, protection systems, and circuit breakers.

- Grid Integration: Analyzing grid capacity and carrying out power flow, fault analysis, and stability studies to ensure the wind farm’s electricity can be effectively integrated with the grid.

- SCADA Systems: Implementing supervisory control and data acquisition (SCADA) systems for real-time monitoring and control of the wind farm’s operations.

7. How do you ensure the design meets regulatory requirements?

We ensure compliance with local, regional, and national regulations by:

- Reviewing applicable grid codes, environmental laws, and zoning requirements.

- Obtaining necessary permits for land use, environmental impact, and construction.

- Coordinating with regulatory bodies to ensure all project designs meet environmental, safety, and operational standards.

- Conducting environmental impact assessments (EIAs) to address potential issues such as wildlife, noise, and visual impact.

8. What is the process for constructing a utility-scale wind farm?

The construction process involves:

- Turbine Assembly & Installation: Installing the turbine foundations, towers, nacelles, and rotors.

- Infrastructure Development: Building access roads, laying cables, and constructing substations.

- Electrical System Installation: Setting up electrical components, including transformers, switchgear, and control systems.

- Safety Compliance: Ensuring all construction activities adhere to safety standards and protocols.

- Quality Control: Monitoring the construction process to ensure the project meets design specifications and regulatory requirements.

10. What is involved in the commissioning and testing phase of a utility-scale wind farm?

The commissioning and testing phase includes:

- Pre-commissioning inspections: To ensure all components are installed correctly.

- Performance testing: Of turbines and electrical systems to verify that they meet design specifications and expected output.

- Grid integration testing: To ensure that the wind farm is capable of delivering power to the grid reliably and within grid codes.

- Optimization of system performance: Based on testing results to maximize energy output and system efficiency.

11. What are the environmental considerations for a utility-scale wind farm?

We address several environmental considerations during the design and construction phases:

- Wildlife Impact: Minimizing harm to local wildlife, such as birds and bats, through careful turbine placement.

- Noise Impact: Ensuring that turbine noise levels comply with local regulations and are minimized.

- Visual Impact: Reducing the aesthetic impact of the turbines on the landscape through site selection and design.

- Land Use: Minimizing land disturbance and ensuring the land can be returned to its natural state after the project’s life.

12. How much do your utility-scale wind farm engineering services cost?

The cost of our utility-scale wind farm engineering services depends on the size and complexity of the project. We offer customized pricing based on the scope of work, including site assessment, design, construction, and commissioning. We work with clients to provide cost-effective solutions that maximize energy production while ensuring quality and regulatory compliance

13. Do you provide ongoing support after the wind farm is operational?

Yes, we provide post-commissioning support, including:

- Ongoing monitoring and performance analysis to ensure optimal operation.

- Maintenance planning and support for addressing any operational issues.

- Upgrades and optimization recommendations to improve efficiency and extend the life of the wind farm.

14. What is wake loss, and why does it matter in wind farm design?

Wake loss happens when one turbine blocks or disturbs the airflow to another, reducing overall efficiency. We use advanced modeling to optimize turbine layouts and minimize wake effects, maximizing energy production across the site.

15. How is wind measured and modeled before building a wind farm?

Accurate wind measurement is crucial. We help deploy LiDAR, SODAR, or meteorological towers to collect data on wind speed, direction, and turbulence. This information guides turbine placement, foundation design, and overall project feasibility.

16. Can Keentel support foundation and civil coordination for the wind farm?

Yes. While our focus is electrical, we work closely with civil and geotechnical teams. We ensure that collector cable trenches, grounding systems, and access roads are fully integrated into the overall site design—reducing conflicts and streamlining construction.

17. Do utility-scale wind farms require SCADA integration, and why is it important?

Absolutely. SCADA systems monitor turbines, substations, and grid interface in real-time. We design SCADA architecture that supports remote diagnostics, performance tracking, and predictive maintenance—ensuring efficient and reliable operations.

18.What is repowering, and when does a wind farm need it?

Repowering means updating aging turbines, generators, control systems, or cable infrastructure to improve performance. Typically undertaken after 15–20 years, repowering helps extend site life, increase efficiency, and comply with modern grid standards.

19.Can wind farms be combined with battery storage systems?

Yes. Integrating wind farms with Battery Energy Storage Systems (BESS) helps smooth out power fluctuations, manage grid demands, and improve energy dispatch. Keentel supports combined wind + storage designs for more flexible and reliable renewable energy projects.