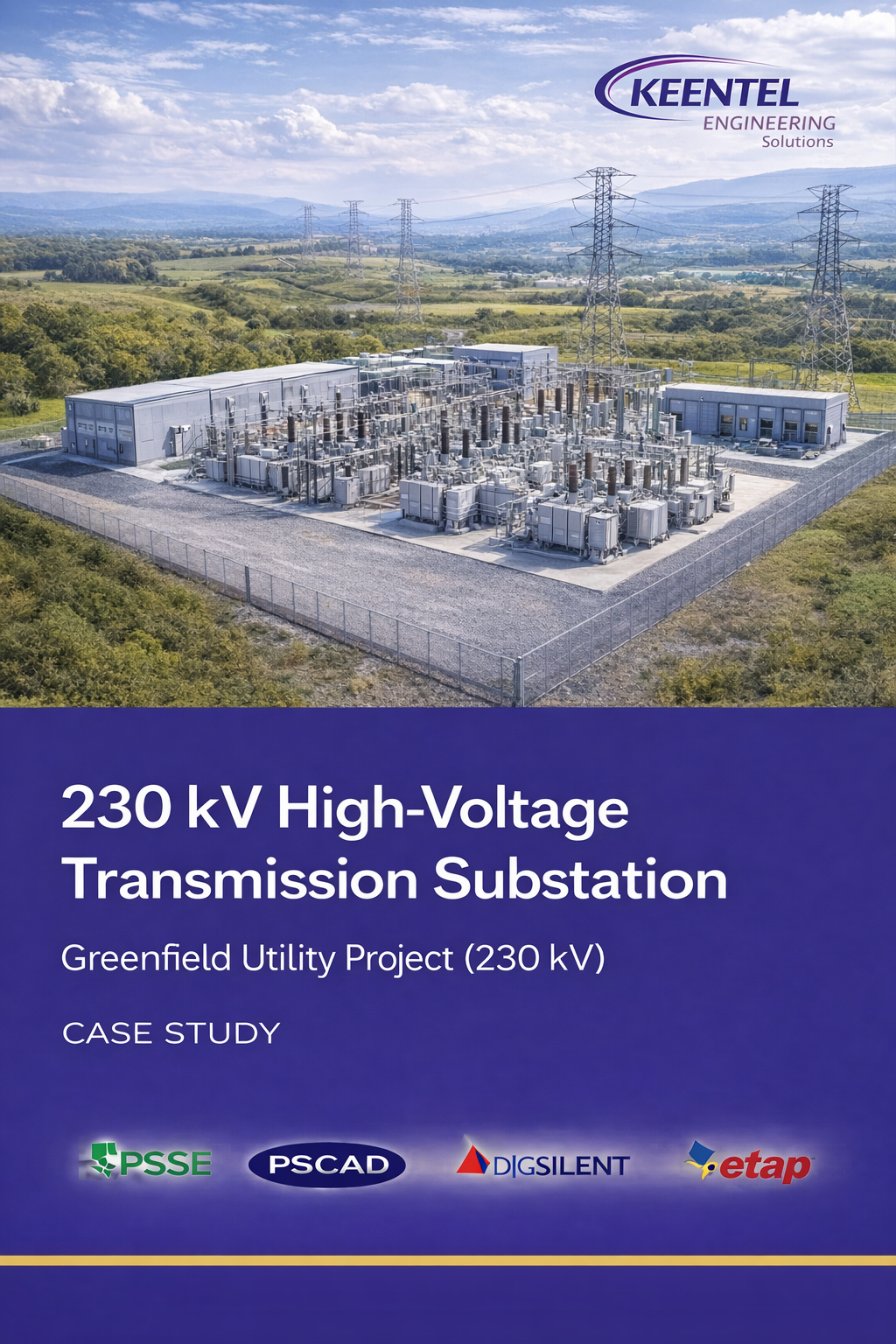

Transmission Substations (69 kV – 500 kV)

High-voltage transmission substation designs engineered for bulk power transfer, N-1 reliability, and grid stability across utility and ISO/RTO networks.

Safe, reliable, and future-ready substation solutions engineered for grid performance, automation, and compliance.

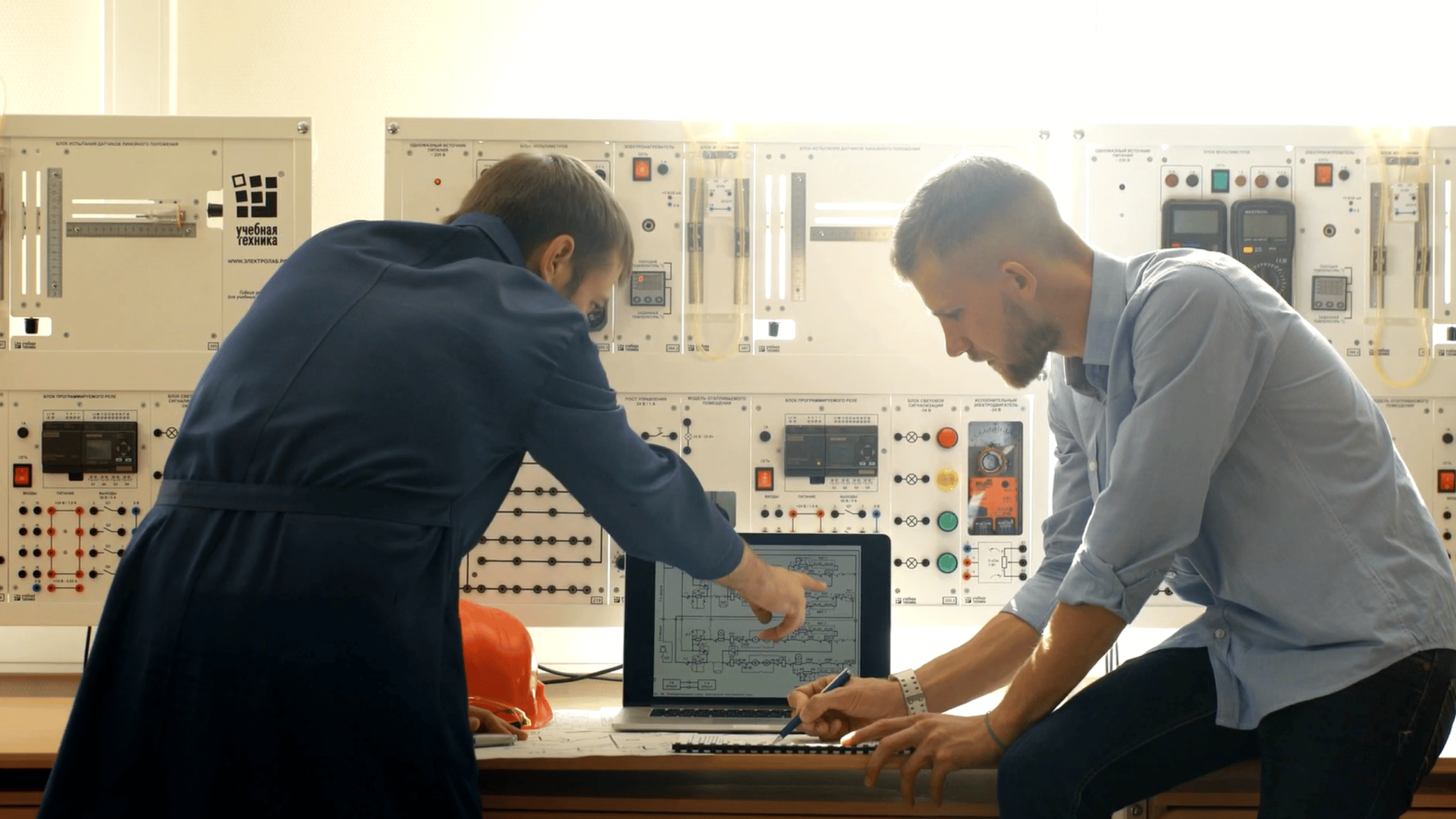

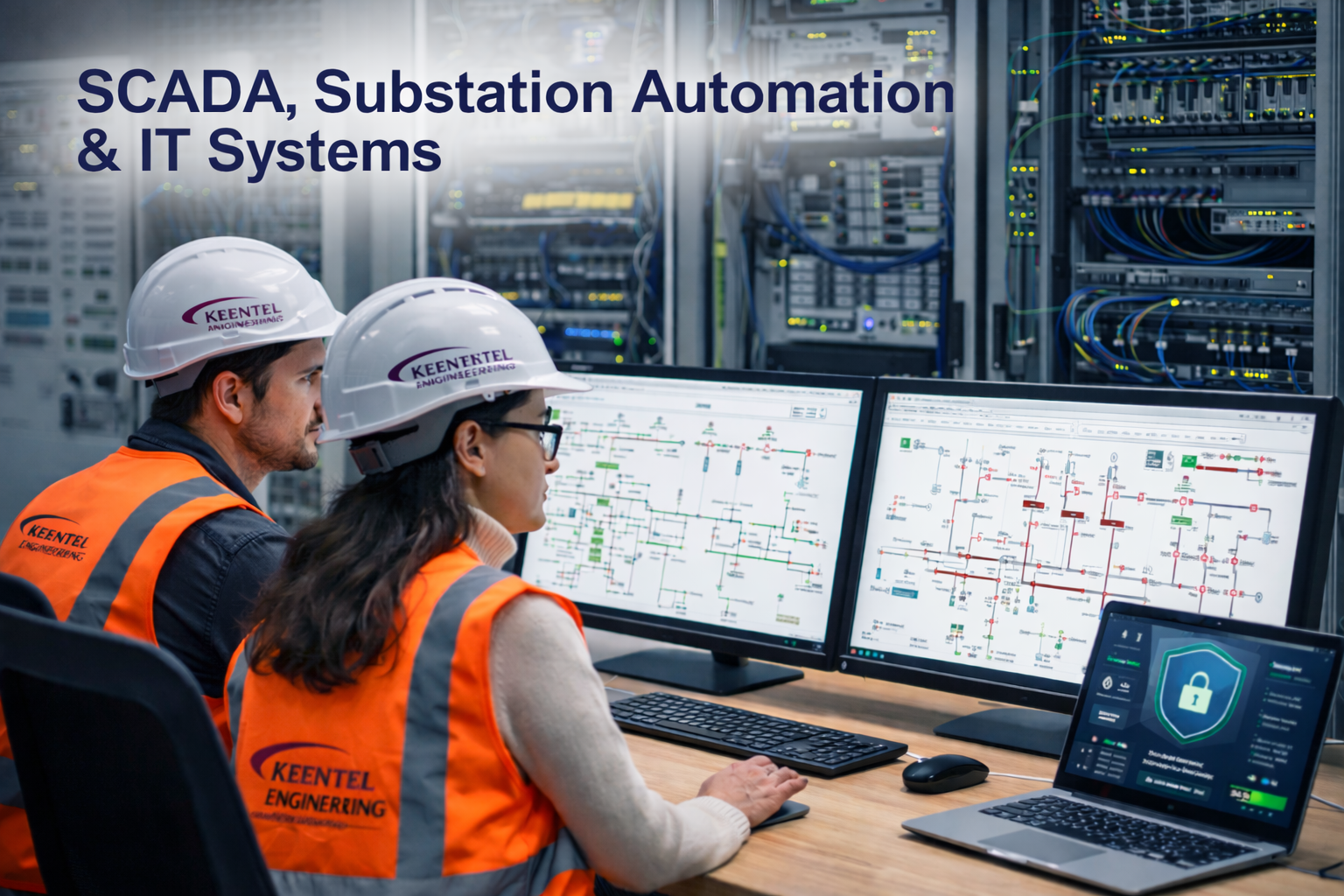

We provide specialized substation design services, including substation electrical engineering, protection & control, SCADA, and power system studies for utilities, renewable energy developers, EPCs, and industrial clients across the United States. Our services focus exclusively on electrical systems, digital substations, communications, and grid integration, ensuring technically sound designs that meet modern operational and cybersecurity expectations.

Our team delivers accurate, compliant, and review-ready substation design packages, engineered for long-term reliability, secure operations, and seamless integration with utility and ISO control environments.

Utility-grade substation design services and electrical engineering, including protection & control, automation, and power system studies, trusted by utilities, EPCs, and energy developers nationwide.

At Keentel Engineering, we take pride in being the go-to electrical power engineering firm for power and utility system planning, substation design, protection, control, and power system analysis. The following attributes distinguish our team in utility-grade substation engineering and compliance-driven project delivery.

With three decades of hands-on project delivery, we bring unmatched expertise in substation layout design, substation electrical and civil engineering, relay protection, and grid-tie solutions. Our experience includes projects in complex terrain, urban retrofit environments, and utility-scale renewable integrations.

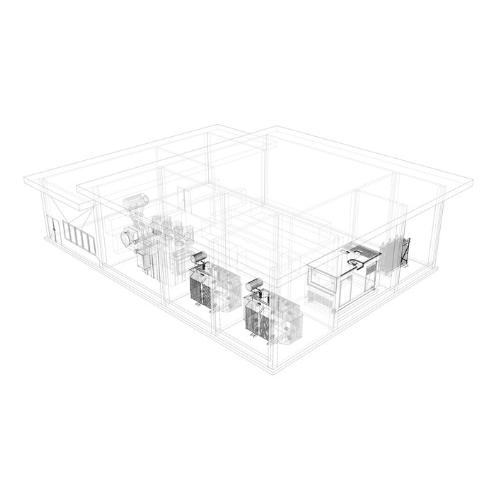

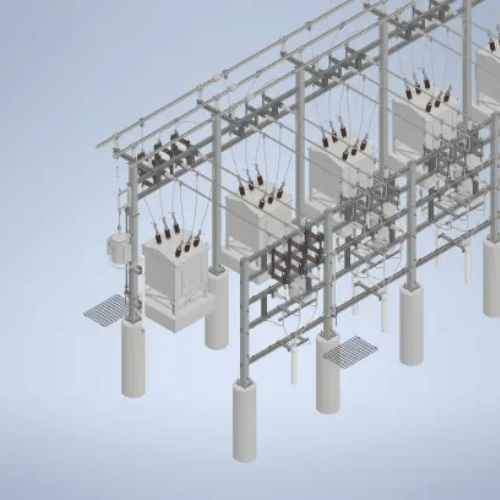

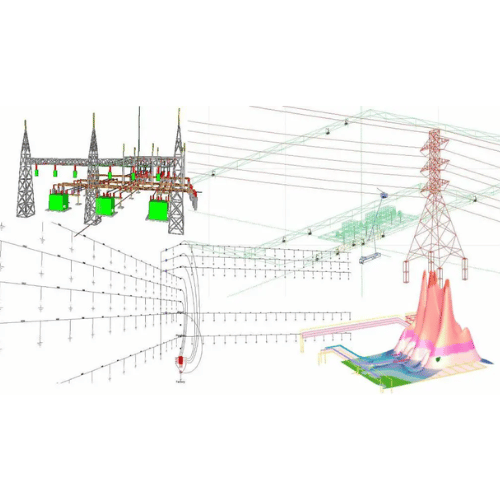

Our engineering process applies AutoCAD 3D, BIM modeling, and system-level substation design practices to ensure accurate planning, reduced errors, and effective coordination across all project stakeholders.

Our workflow includes 3D substation design, enabling clash-free coordination between structural, electrical, and civil disciplines.

From grounding grid studies to relay protection settings, we engineer every detail to improve system reliability, performance, and operational safety. Our rigorous QA/QC process ensures compliance with IEEE, NFPA, and ISO/TSO interconnection standards.

Among leading electrical substation design companies, Keentel Engineering stands out for 30+ years of proven high-voltage and utility-grade project delivery.

Let's Discuss How to Optimize Your Next Project

Modern substations must be engineered as integrated electrical, protection, communication, and digital systems. Today’s grid demands reliability, regulatory compliance, cybersecurity awareness, and seamless inverter-based resource (IBR) integration—not isolated drawings or disconnected studies.

Dependable substation capacity engineering designed for load growth, future expansion, N-1 contingencies, and renewable generation variability to support long-term system reliability.

Substation protection and automation engineering with selective, coordinated protection schemes and relay automation for fast fault isolation, system stability, and safe restoration.

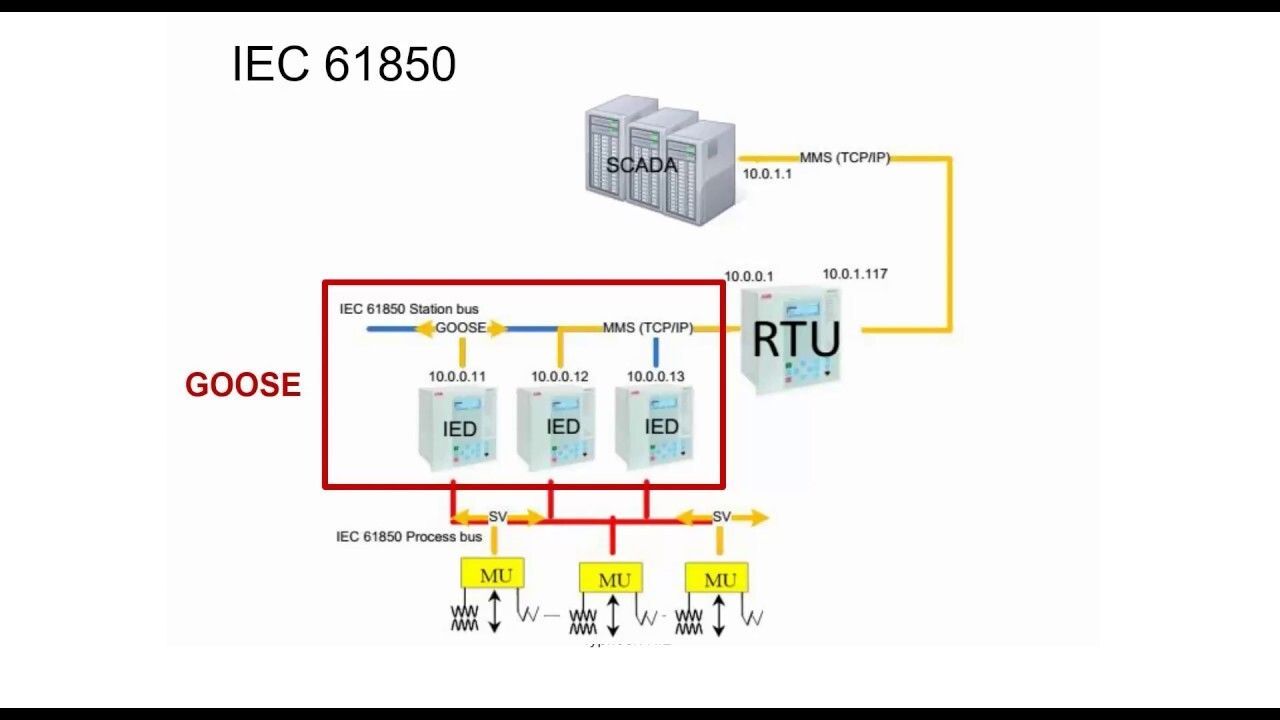

SCADA and digital substation systems with interoperable architectures integrated into utility EMS and DMS platforms for secure monitoring and operational control.

Substation standards and regulatory compliance engineering aligned with NERC, IEEE, NEC, NESC, IEC 61850, and utility-specific requirements to support smooth approvals and audit readiness.

Cyber-aware substation architecture with redundant, fault-tolerant network and control system designs addressing operational resilience and cybersecurity considerations.

IBR integration and power system studies using advanced modeling, protection strategies, and control coordination for solar, wind, and BESS interconnections.

Download our Substation Design Services flyer

Please click the Download button to get our Substation Design Services flyer

End-to-end substation design services, including substation electrical engineering, protection & control, SCADA, and power system studies— from early feasibility through Issue-for-Construction (IFC) packages and commissioning support.

Conceptual substation configurations, preliminary studies, and technical assessments supporting interconnection requirements, project budgeting, and early risk reduction.

Primary, secondary, and auxiliary substation electrical systems, including protection and control engineering, aligned with utility standards and ISO/RTO requirements.

General arrangements, equipment layouts, electrical clearances, control houses, and cable routing concepts designed for constructability and operational access.

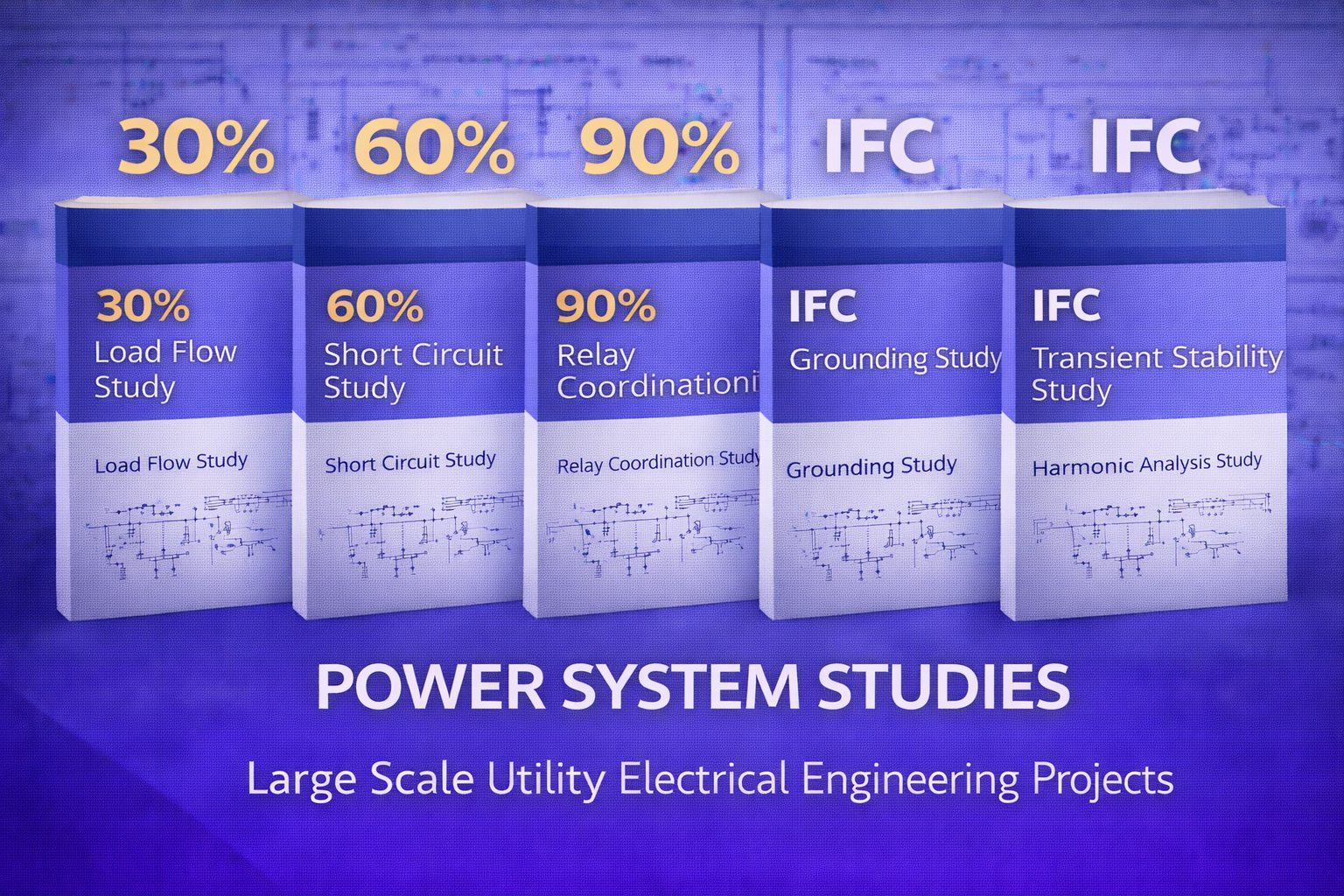

Comprehensive power system studies for substations, including load flow, short-circuit, grounding, arc-flash, coordination, and EMT analysis.

Secure SCADA and substation automation architectures with EMS/DMS integration, communications design, and cybersecurity-aware system planning.

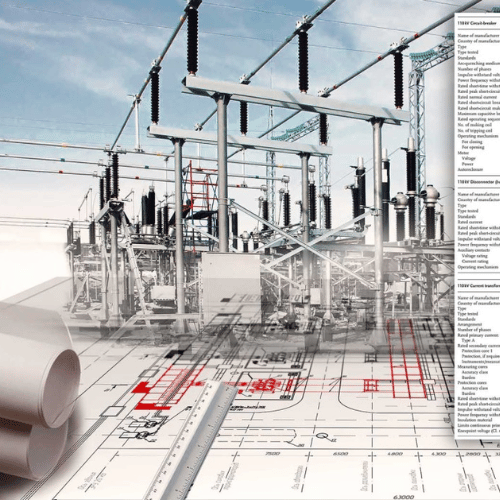

Construction-ready substation drawings and calculations, including schematics, wiring diagrams, logic diagrams, and detailed design documentation.

Equipment and material specifications, relay and control requirements, and engineering support for procurement and vendor coordination.

Independent QA/QC reviews, compliance verification, and complete IFC substation design packages prepared for utility submission and construction.

Engineering support during installation, testing, energization, and project handover to ensure designs perform as intended in the field.

Utility-grade substation design services, including electrical engineering, protection & control, SCADA, and power system studies—engineered for reliability, automation, and regulatory compliance.

Utility-grade substation design services, including electrical, protection, and automation engineering across all voltage levels and applications. Each substation design is driven by power system studies, protection philosophy, and operational requirements to ensure long-term performance, reliability, and regulatory compliance.

High-voltage transmission substation designs engineered for bulk power transfer, N-1 reliability, and grid stability across utility and ISO/RTO networks.

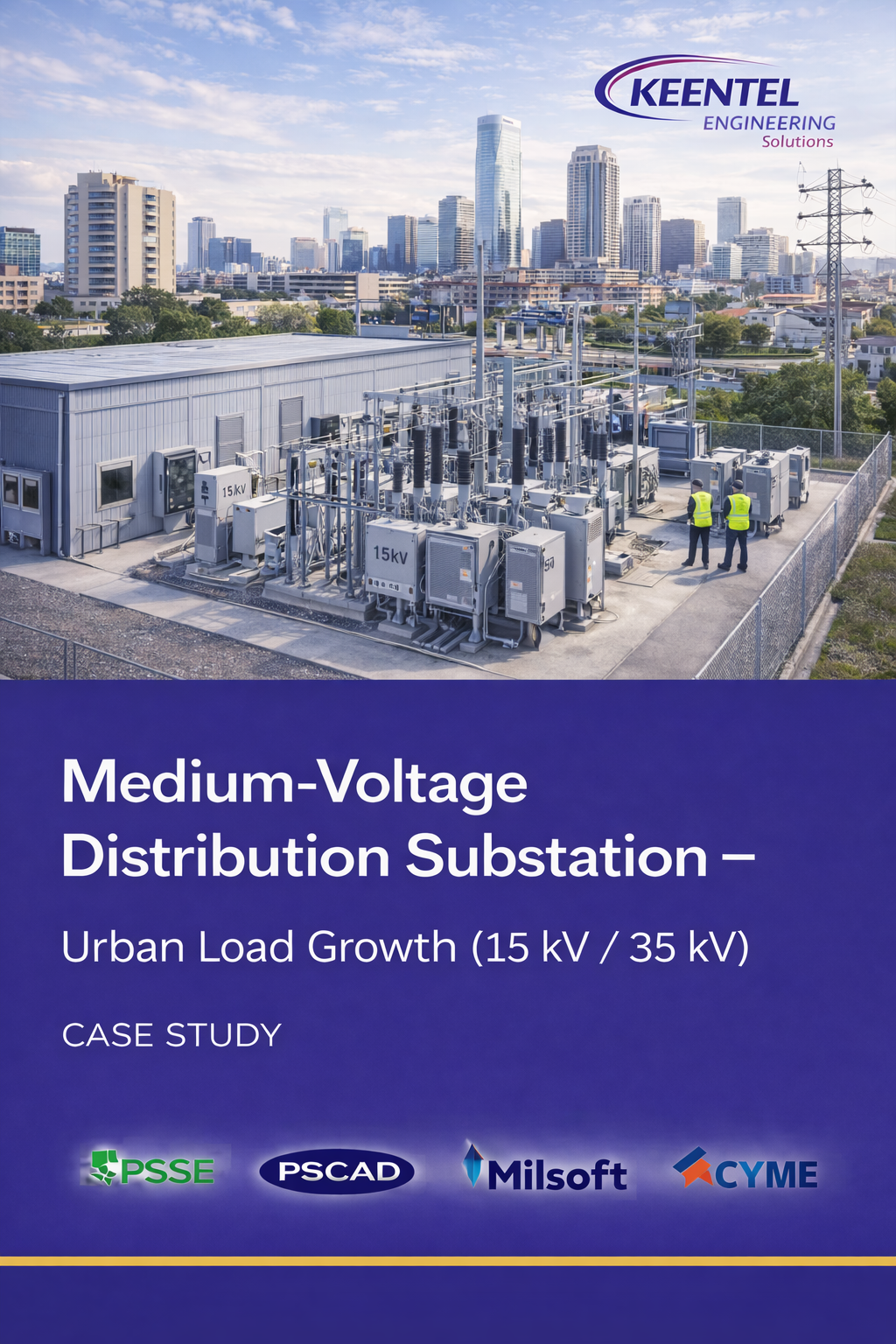

Medium-voltage distribution substation designs supporting utility and municipal distribution systems, feeder reliability, and operational flexibility.

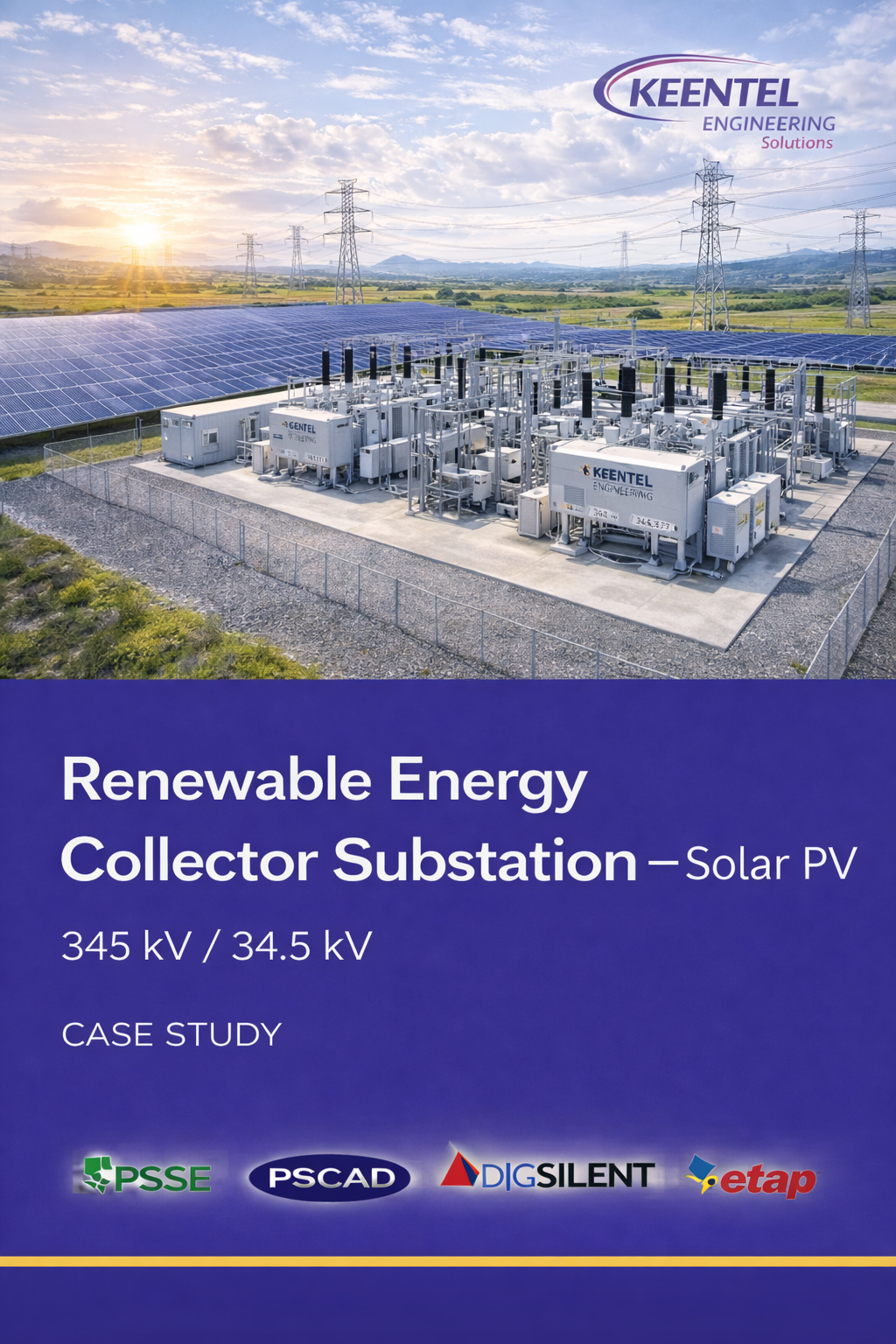

Optimized collector substation electrical and protection designs for inverter-based renewable resources, supporting grid-code compliance and interconnection requirements.

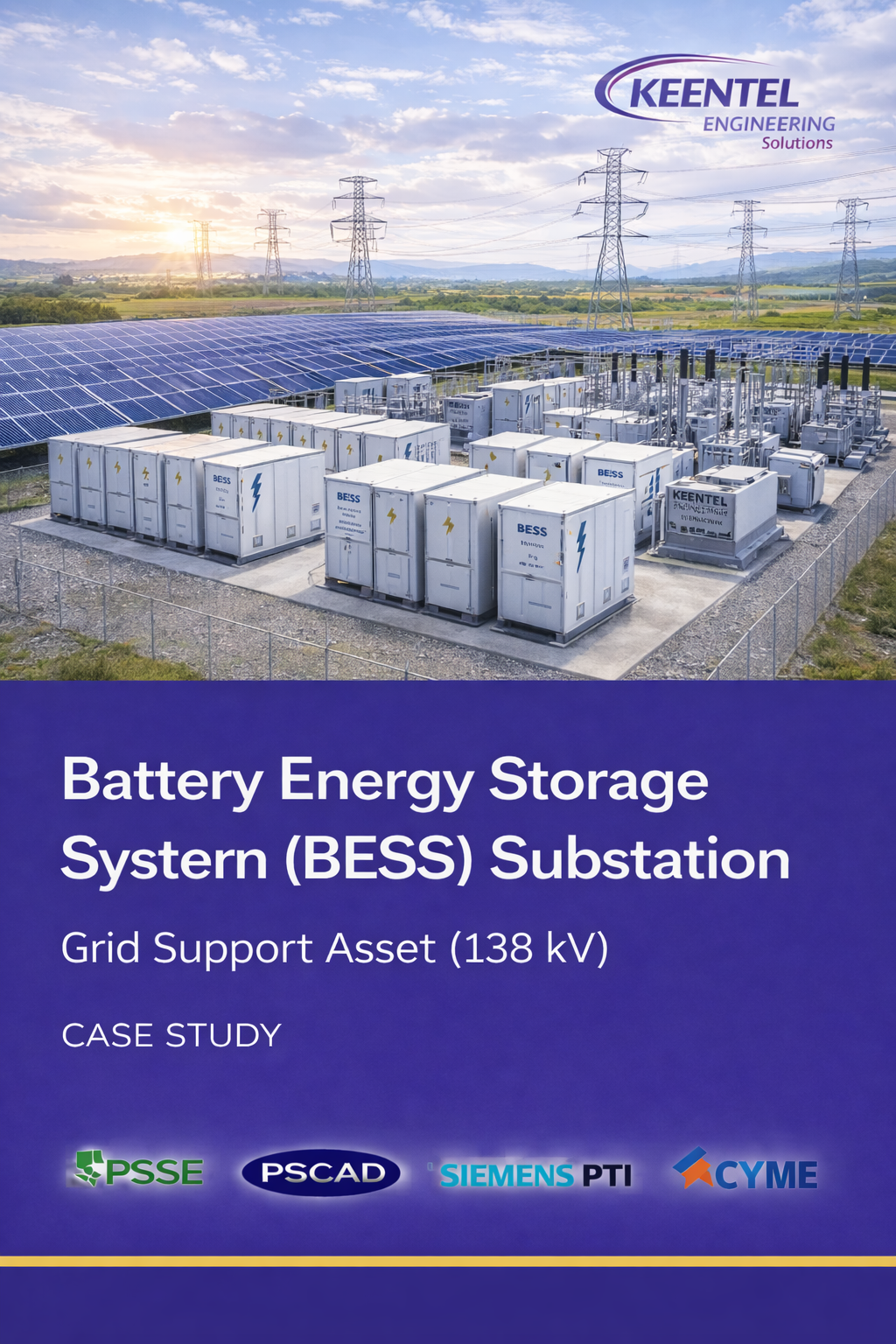

Substation designs supporting battery energy storage system (BESS) interconnections, fast-response operation, and advanced protection and control strategies.

Reliable industrial and commercial substation designs serving data centers, manufacturing plants, processing facilities, and campus-style loads.

Compact GIS substation designs and traditional AIS substations engineered for operational flexibility, footprint constraints, and long-term maintainability.

Electrically optimized urban substation designs developed for dense environments, restricted footprints, and complex site constraints.

Substation modernization and retrofit designs supporting equipment replacement, protection upgrades, and cutover strategies that minimize outages and operational risk.

Rapid-deployment mobile and temporary substation solutions supporting emergency response, maintenance bypass, and system restoration.

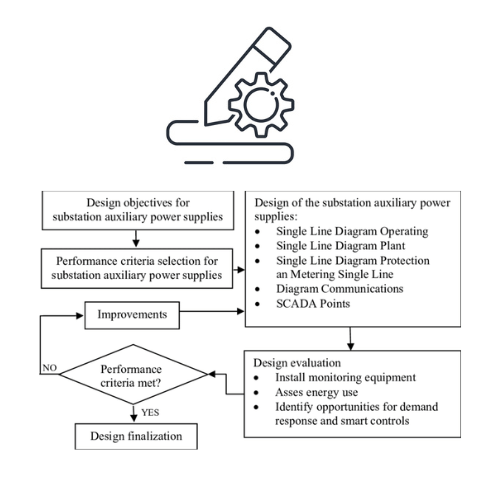

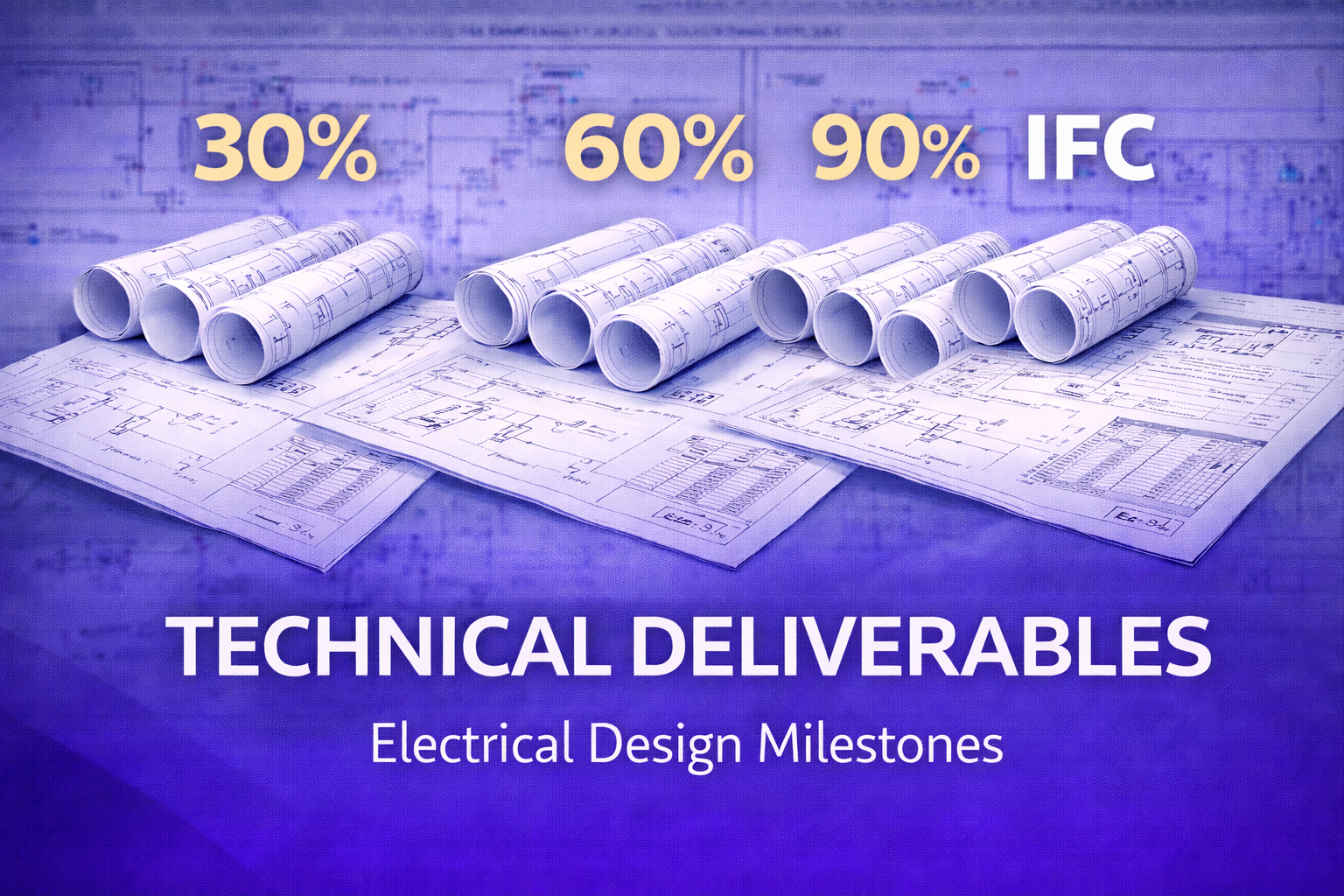

A clear, step-by-step substation design and engineering workflow aligned with utility standards, constructability, and long-term operational reliability.

Evaluation of load growth, voltage class, utility design standards, permitting requirements, and protection philosophy to establish project scope and technical constraints.

Site-specific geotechnical review, grounding constraints, access planning, EMF considerations, and early regulatory and utility coordination.

Development of preliminary substation layouts, bus configurations, telecommunications architecture, and early-stage power system modeling.

Integrated substation electrical engineering, civil and structural design, grounding, and protection & control (P&C) coordination.

Preparation of construction-ready calculations, power system studies, IFC drawings, and detailed bills of material.

Independent QA/QC reviews, compliance verification, and cross-discipline validation aligned with utility and regulatory requirements.

Formal utility submissions, authority coordination, comment resolution, and final design approvals.

Engineering support for RFIs, field clarifications, relay testing, commissioning activities, and energization coordination.

Our engineering approach combines deep technical knowledge, regulatory alignment, and constructible delivery — ensuring safer operations and predictable construction outcomes.

Delivered substation projects across utilities, voltage classes, and ISO/RTO regions with consistent, repeatable results.

Deliverables aligned to utility templates and compliance requirements to reduce review cycles.

Digital workflows and model-based coordination reduce errors and shorten schedules.

IBR modeling, EMT studies, and inverter-specific protection strategies embedded in our designs.

Constructible packages and pre-construction reviews minimize rework and delays.

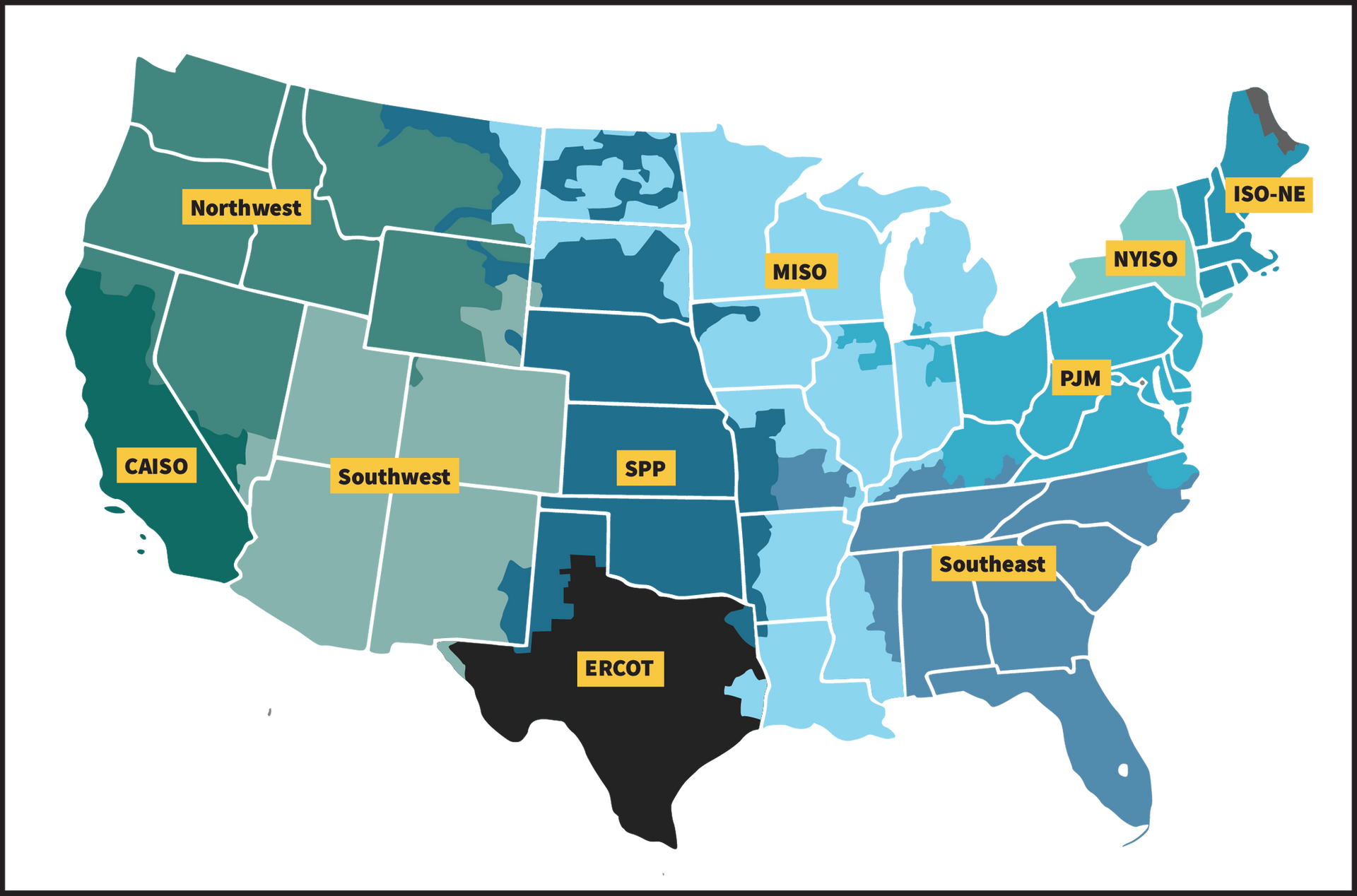

Licensed engineers across ERCOT, PJM, CAISO, MISO, NYISO, SPP, and municipal utilities.

We partner with stakeholders across the power sector and critical infrastructure to deliver substation designs that align with regulatory, operational, and commercial objectives.

Transmission and distribution substations designed to meet utility standards, reliability targets, and long-term asset plans.

Project-ready substation designs aligned with PPA terms, interconnection milestones, and financing requirements.

Collector and POI substation designs tailored to inverter-based resources, grid-code compliance, and curtailment risk.

Constructible, clearly scoped engineering packages that reduce change orders and align tightly with EPC schedules.

Dedicated substations for refineries, manufacturing plants, mining, steel, and other energy-intensive operations.

High-availability substation designs for campus-style loads, Tier-certified data centers, and mission-critical facilities.

Real-world substation engineering delivered across rural electrification, smart cities, renewable energy, and space-constrained urban environments.

Every project includes a complete and coordinated set of engineering studies, models, and documentation aligned with utility, NERC, IEEE, and project-specific requirements.

Our substation engineering is fully aligned with national, regional, and utility-specific compliance requirements to ensure smooth approvals, safe operation, and audit-ready documentation.

Designs follow IEEE standards for equipment ratings, grounding, protection, and electrical safety.

Compliance with electrical code and safety standards governing clearances and work practices.

Model validation, protection coordination, and facility ratings requirements built into every project.

Substation layouts and drawings aligned to each utility’s preferred methods and review formats.

Engineering aligned with PJM, MISO, CAISO, ERCOT, and other regional requirements.

Substation automation, GOOSE messaging, and digital architecture built to IEC standards.

We deliver high-performance renewable substation engineering built for fast-changing inverter technologies, variable generation, and modern grid requirements.

Substation layouts, grounding, power flow, and protection tailored for high-density solar arrays.

Engineered to handle variable wind generation, changing dispatch, and remote collection circuits.

Full-scope substation design for hybrid resources, standalone batteries, and high-speed response systems.

Correct matching of inverter output, transformer MVA, impedance, and protection for reliable performance.

Design aligned with PRC, MOD, and evolving IBR interconnection and grid-support requirements.

Analysis and design that ensure stable power quality on weak and constrained grids.

Fault-level support strategies for weak-grid renewables, including advanced IBR behavior modeling.

Most substation and grid-interconnection projects require a core set of power system studies. The matrix below summarizes why each analysis is performed and where it is typically required.

| Study | Purpose | Required For |

|---|---|---|

| LF

Load Flow

|

Validate system capacity and identify thermal or voltage constraints. | Utilities, developers, and large-load customers. |

| SC

Short Circuit

|

Confirm breaker duties and protection coordination. | All substations and major equipment additions. |

| AF

Arc-Flash

|

Quantify incident energy and define safe working boundaries. | OSHA, NFPA 70E, and utility safety programs. |

| GR

Grounding

|

Verify touch and step voltages and grid performance. | IEEE 80 and utility requirements. |

| HM

Harmonics

|

Assess harmonic distortion from inverter-based resources. | Solar, wind, BESS, and IBR-heavy projects. |

| IC

Insulation Coordination

|

Select BIL levels and surge protection. | High-voltage and transmission-class substations. |

Project cost and schedule depend on technical scope, utility requirements, and site complexity. Below is a high-level summary of factors that typically influence budgets and timelines.

We support utilities, EPCs, renewable developers, and industrial clients across major North American regions and nearby territories.

Serving utilities, EPCs, developers, and infrastructure organizations supporting critical power systems nationwide.

Download our Substation Design Services flyer

Please click the Download button to get our Substation Design Services flyer

We stay current on the latest utility and smart grid standards. Our engineers design substations that are built for future expansion, automation, and integration with digital relays, smart SCADA, and real-time monitoring systems.

We don’t just meet specs — we shape systems that align with your long-term grid strategy.

For more information or service assistance, call us on 813-389-7871.

Substation services include the design, engineering, protection, automation, and analysis of facilities that transform voltage levels, control power flow, and protect electrical networks. Substations are critical to ensuring safe, reliable, and efficient delivery of electricity from generation sources to transmission and distribution systems.

A substation designer develops detailed engineering drawings and technical documentation required to construct or upgrade substations. This includes general arrangements, equipment layouts, wiring diagrams, control schematics, material lists, and cable schedules, working closely with electrical, protection, and civil engineers to ensure constructible and utility-accepted designs.

Key components typically include:

Primary considerations include voltage level, load growth, fault levels, site conditions, grounding, safety, environmental constraints, constructability, and compliance with standards such as IEEE, NEC, NESC, IEC, and utility-specific requirements.

Substation layout is determined based on available space, voltage class, bus configuration, reliability requirements, safety clearances, and operational flexibility. Engineers use single-line diagrams, equipment clearances, and constructability reviews to develop optimal layouts.

Substation design typically follows:

Voltage levels are selected based on system requirements, transmission distance, load demand, and interconnection constraints. Common transmission and sub-transmission levels include 69 kV, 115 kV, 230 kV, and 500 kV, depending on the application.

Grounding design ensures personnel safety, equipment protection, and system reliability. Engineers evaluate soil resistivity, ground grid resistance, and step-and-touch voltage limits in accordance with IEEE 80 and utility standards.

Short-circuit current is calculated using power system analysis software such as ETAP, PSS®E, or PSCAD, considering system impedance, transformer ratings, and network configuration to verify breaker duties and protection coordination.

Protection and Control (P&C) systems monitor substation conditions and detect, isolate, and clear faults using protection relays, circuit breakers, and automation logic, ensuring system stability and equipment protection.

Common schemes include:

Relay selection is based on voltage level, fault characteristics, system configuration, and utility standards. Common relay platforms include SEL, GE, ABB, and Siemens, configured to meet project-specific protection philosophies.

SCADA systems provide remote monitoring, control, and data acquisition for substation equipment, improving operational visibility, response time, and system reliability through integration with utility EMS and DMS platforms.

Substation projects typically range from 12 to 36 months, depending on voltage level, site conditions, equipment lead times, permitting, and utility review cycles.

Commissioning generally includes:

Safety measures include PPE requirements, grounding practices, arc-flash assessments, lockout/tagout procedures, and compliance with OSHA and utility safety programs.

Substations are monitored through SCADA systems and maintained using routine inspections, testing, and condition-based maintenance to ensure long-term reliability.

Periodic testing verifies equipment performance, identifies degradation early, and ensures continued compliance with reliability and safety standards.

Thermal imaging identifies abnormal heating in transformers, breakers, and connections, helping prevent failures and unplanned outages.

A digital substation uses IEC 61850-based communication, replacing conventional copper wiring with fiber-optic networks to improve data accuracy, reliability, and scalability.

Renewable resources are connected through collector systems and step-up substations, with designs addressing inverter behavior, protection coordination, harmonics, and grid-code compliance.

Keentel Engineering specializes in utility-grade substation protection and control engineering, including relay coordination, SCADA/RTU configuration, and control building integration for transmission, distribution, and renewable substations across the U.S.

Serving for more than two decades, we are a name you can trust and count on for your power system and engineering support needs. We can provide innovative solutions to take your business to greater heights.

400 N Ashley Dr STE #2600

Tampa, FL 33602

Copyright 1995-2026 Keentel Engineering All Rights Reserved