A Coordinated Electric System Interconnection Review—the utility’s deep-dive on technical and cost impacts of your project.

Guide to Substation Design and Engineering – Keentel Engineering

May 12, 2025 | Blog

Introduction

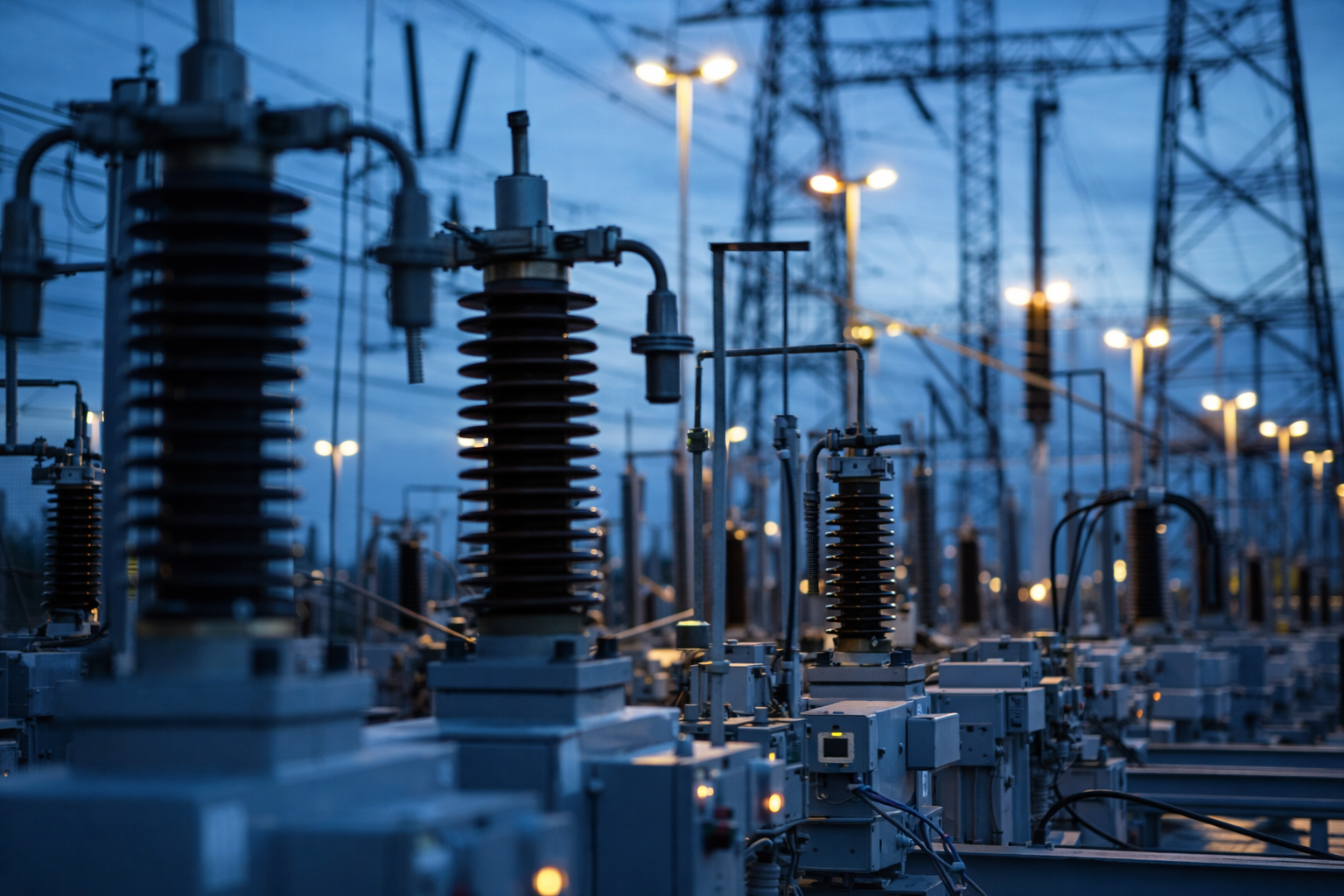

In today’s modern power systems, substations are critical nodes that manage the flow of electricity between generation and consumption. Keentel Engineering leverages cutting-edge tools and industry expertise to design, simulate, and support substation engineering across voltage levels and operational requirements. A structured approach to substation planning ensures system reliability, regulatory compliance, and long-term operational performance.

What is a Substation?

A substation is a crucial part of the electrical grid where voltage levels are transformed, and power is routed safely. They are equipped with components such as transformers, bus-bars, circuit breakers, and protection devices to maintain efficient and secure electrical transmission and distribution. Modern facilities increasingly support substation electrification initiatives and advanced grid automation requirements.

Key Types of Substations

Substations are categorized by their:

- Purpose: Generating, Grid, Distribution, and Special-Purpose

- Construction: Outdoor, Indoor, Pole-Mounted, Underground

Each classification influences layout, equipment selection, and protection philosophy, particularly for hv substation design and engineering projects serving transmission networks.

Steps in Substation Design

At Keentel Engineering,

substation design follows a methodical 8-step approach:

- Switching System Selection: Defines system reliability (e.g., ring bus, breaker-and-a-half), commonly applied in primary substation layout engineering.

- Key Planning: Layout of all equipment and infrastructure, supporting constructability and future expansion.

- Equipment Selection: Aligning with operational requirements and applicable standards.

- Engineering & Licensing: Includes P.E. sealed drawings and public testimony, supporting electric substation project engineering approvals.

- Civil & Structural Design: Pile foundation, control house, steel structures, addressing substation civil engineering design, substation structural engineering design, and substation foundation engineering design considerations.

- Electrical Layout: Equipment positioning, bus-bar design, grounding, and substation dc system design integration.

- Control Design: Protection schematics, SCADA integration, and coordination of substation protection and control equipment.

- Construction Support: Field assistance, design modifications, and coordination during substation civil construction.

Get More Info About Keentel Substation Design Services

Bus-Bar Arrangements

Effective bus-bar selection ensures reliability and operational flexibility. Topologies include:

- Single Bus

- Double Bus with Single/Double Breaker

- Breaker-and-a-Half

- Ring Bus

- Main and Transfer Bus systems

Bus selection plays a direct role in substation reliability and long-term maintenance efficiency.

Substation Engineering Studies

Keentel Engineering conducts detailed simulations and analysis using ETAP, including comprehensive substation modeling services that support system validation and optimization:

- Load Flow & Short-Circuit Analysis

- Insulation Coordination

- Protection & Control

- Ground Grid & Lightning Protection

- Voltage Drop and Conduit Fill

- Structural and Geotechnical Studies supporting substation engineering design civils and geotechnical requirements

These studies form the backbone of accurate grid simulation & substation performance assessments.

Diagramming and Documentation

Proper documentation such as Single Line Diagrams (SLD), relay schematics, grounding layouts, and lighting plans are essential to streamline construction, operation, and maintenance. This documentation approach aligns with best practices outlined in a substation structure design guide and supports electric substation civil structural design workflows.

Why Choose ETAP for Simulation?

ETAP provides a digital twin environment for analysis, optimization, and fault prevention. Keentel uses ETAP for:

- Enhanced reliability

- Energy efficiency

- Simulation accuracy

ETAP is also critical for substation modeling in complex interconnection and expansion projects.

Conclusion

Keentel Engineering provides end-to-end services in substation design and engineering, including detailed drawings, studies, and regulatory support. Our commitment ensures cost-effective and reliable infrastructure aligned with modern grid requirements, including electrical substation design solutions and substation engineering solutions delivered across utility, industrial, and renewable sectors.

Why Choose Keentel Engineering

Keentel Engineering brings a practical, engineering-driven approach to substation design and analysis. Our team supports utilities, developers, and industrial clients with technically sound solutions that align with regulatory requirements and real-world operating conditions.

Comprehensive engineering expertise

We provide end-to-end substation engineering support, covering civil, structural, electrical, protection, and control disciplines.

Proven simulation and study capabilities

Our ETAP-based studies help validate designs, reduce risk, and improve system performance before construction begins.

Experience across diverse project types

From utility-scale transmission facilities to industrial and renewable interconnections, we design substations that meet project-specific demands.

Focus on reliability and compliance

Our designs prioritize system reliability, personnel safety, and alignment with applicable standards and interconnection requirements.

Collaborative project delivery

We work closely with stakeholders throughout planning, design, and construction to ensure clear communication and dependable outcomes.

Case Studies

Case Study 1: 110kV Outdoor Grid Substation – Rural Electrification Project

Location: West Texas

Challenge: Design a reliable substation in a remote location with harsh environmental conditions.

Solution: Keentel implemented a double bus with transfer scheme, performed grounding studies, and optimized protection using ETAP.

Outcome: 99.9% uptime, completed 2 weeks ahead of schedule.

Case Study 2: Indoor Substation Retrofit for Smart City Hub

Location: Atlanta, GA

Challenge: Upgrade aging indoor substation with minimal downtime.

Solution: Modeled full SLD, performed load flow, short-circuit studies in ETAP, and designed SCADA-ready control schemes.

Outcome: Enhanced automation and 40% reduction in operational faults.

Case Study 3: GIS-Based Urban Substation for Space Constraints

Location: Downtown Chicago

Challenge:

Limited space required Gas-Insulated Switchgear (GIS) implementation.

Solution:

Developed 3D electrical layout, performed lightning protection and structural studies.

Outcome: Safe, compact solution operational within 4 months.

Case Study 4: 220kV Renewable Energy POI Substation

Location: Mojave Desert, CA

Challenge:

Interconnect a 150 MW solar plant to the grid.

Solution:

ETAP-based short-circuit and harmonic analysis, and relay coordination.

Outcome: Fully compliant design delivered under NERC/ISO requirements.

Case Study 5: Industrial Substation with Heavy Motor Loads

Location: Gulf Coast, TX

Challenge:

Design a substation for a chemical plant with large MV motors.

Solution:

Voltage drop, conduit fill, and bus-bar heat rise analysis performed.

Outcome:

Efficient power delivery and fault-tolerant design ensured safety and continuity.

Frequently Asked Questions (FAQs)

What is a substation in electrical engineering?

A facility where voltage is transformed and electrical power is routed using transformers, breakers, and protective systems.

Why are substations important?

They manage and direct power flow, maintain voltage levels, and ensure grid reliability.

What are the main components of a substation?

Power transformers, bus-bars, circuit breakers, insulators, lightning arresters.

What are the types of substations based on purpose?

Generating, Grid, Distribution, Secondary, and Special Purpose.

What bus-bar arrangement is best for reliability?

Breaker-and-a-half and Ring Bus offer high reliability and redundancy.

What is the role of a Single Line Diagram (SLD)?

It provides a simplified yet detailed layout of electrical connections and components.

Why is grounding essential in substation design?

To ensure personnel safety and equipment protection from fault currents.

What is insulation coordination?

It ensures dielectric strength and proper clearances based on voltage and BIL ratings.

What is SCADA in substations?

Supervisory Control and Data Acquisition system for real-time monitoring and control.

Why use ETAP software in design?

For accurate load flow, fault studies, and design optimization.

What is load flow analysis?

A study to determine voltage, current, and power flow across the network.

What is a short-circuit study?

It analyzes the system response to fault conditions and helps size protective devices.

What is a ring bus configuration?

A closed-loop bus design offering multiple paths for power flow, increasing reliability.

How is civil design integrated in substation engineering?

Includes foundation, structural steel, and control house layout design.

What are the steps to design a substation?

From switching system to construction support – 8 steps total.

How are batteries used in substations?

In DC systems for relay protection and emergency control.

What are auxiliary AC systems?

They supply power to internal substation systems like lighting and HVAC.

What is voltage drop calculation?

Analysis to ensure acceptable voltage at end-use equipment under load.

How are lightning protections designed?

Using ground rods, air terminals, and shielding to divert surges.

What is conduit fill analysis?

Calculates cable size and quantity that can be installed within a conduit safely.

What drawings are used in protection design?

Relay schematics, DC/AC diagrams, panel layouts, SCADA diagrams.

How is noise controlled in substations?

Through placement, sound barriers, and low-noise equipment.

What is the benefit of a double bus with bypass isolators?

Flexibility in maintenance while ensuring continuous power.

Why perform geotechnical investigations?

To ensure stable foundation design and prevent structural failure.

How does ETAP improve energy efficiency?

By simulating system operations to reduce losses and optimize asset performance.

Need expert substation design support?

Keentel Engineering offers full-scope design, simulation, and compliance support for grid-scale, renewable, and industrial substations.

About the Author:

Sonny Patel P.E. EC

IEEE Senior Member

In 1995, Sandip (Sonny) R. Patel earned his Electrical Engineering degree from the University of Illinois, specializing in Electrical Engineering . But degrees don’t build legacies—action does. For three decades, he’s been shaping the future of engineering, not just as a licensed Professional Engineer across multiple states (Florida, California, New York, West Virginia, and Minnesota), but as a doer. A builder. A leader. Not just an engineer. A Licensed Electrical Contractor in Florida with an Unlimited EC license. Not just an executive. The founder and CEO of KEENTEL LLC—where expertise meets execution. Three decades. Multiple states. Endless impact.

Services

Let's Discuss Your Project

Let's book a call to discuss your electrical engineering project that we can help you with.

About the Author:

Sonny Patel P.E. EC

IEEE Senior Member

In 1995, Sandip (Sonny) R. Patel earned his Electrical Engineering degree from the University of Illinois, specializing in Electrical Engineering . But degrees don’t build legacies—action does. For three decades, he’s been shaping the future of engineering, not just as a licensed Professional Engineer across multiple states (Florida, California, New York, West Virginia, and Minnesota), but as a doer. A builder. A leader. Not just an engineer. A Licensed Electrical Contractor in Florida with an Unlimited EC license. Not just an executive. The founder and CEO of KEENTEL LLC—where expertise meets execution. Three decades. Multiple states. Endless impact.

Leave a Comment

We will get back to you as soon as possible.

Please try again later.

Related Posts