A Coordinated Electric System Interconnection Review—the utility’s deep-dive on technical and cost impacts of your project.

Challenge: Frequent false tripping using conventional electromechanical relays

Solution: SEL-487E integration with multi-terminal differential protection and dynamic inrush restraint

Result: 90% reduction in false trips, saving over $250,000 in downtime

Revolutionizing Control System Validation: Hardware-in-the-Loop Simulation with MATLAB and Simulink

July 31, 2025 | Blog

Introduction

In the ever-evolving landscape of industrial automation and control systems, accuracy, efficiency, and safety are paramount. Modern systems are becoming increasingly complex, involving intricate algorithms and sophisticated hardware. As control systems become more intricate, so do the challenges of validating their effectiveness and reliability. Engineers and developers face high stakes when deploying new control logic into physical systems. A single undetected bug can lead to costly downtime, damaged machinery, or even personal injury.

To mitigate these risks, engineers have long sought ways to test and validate control algorithms thoroughly before deploying them on actual equipment. Enter

Hardware-in-the-Loop (HIL) Simulation using

MATLAB and Simulink. This revolutionary approach enables engineers to test control algorithms in a real-time environment that replicates the behavior of actual hardware systems. The result? Faster development cycles, reduced risk, lower costs, and improved reliability.

This blog dives deep into the methodology, tools, and applications of HIL simulation using MATLAB, Simulink, and Speedgoat hardware. From understanding traditional challenges to embracing modern solutions, this guide is your comprehensive resource for mastering HIL simulations in control system validation.

Traditional Challenges in Control Algorithm Testing

Control systems often encompass a combination of mechanical components, electrical circuits, embedded controllers, and software algorithms. Traditionally, these systems undergo validation through a mix of desktop simulations and direct hardware testing. While this approach is functional, it is riddled with challenges:

- Late Error Discovery: Integration mistakes are often detected in the later stages, making rectification more costly and time-consuming.

- High Prototype Risks: Testing on physical prototypes can cause damage to expensive equipment if something goes wrong.

- Limited Test Scenarios: Testing under extreme or dangerous conditions (e.g., high pressure, deep sea, high temperature) is often impractical.

- Downtime Costs: System failures during validation can lead to production halts and financial loss.

In addition to these challenges, testing controllers under all possible fault conditions and failure modes in the real world is often impossible or unsafe. This is where HIL simulation enters the picture as a game-changing methodology.

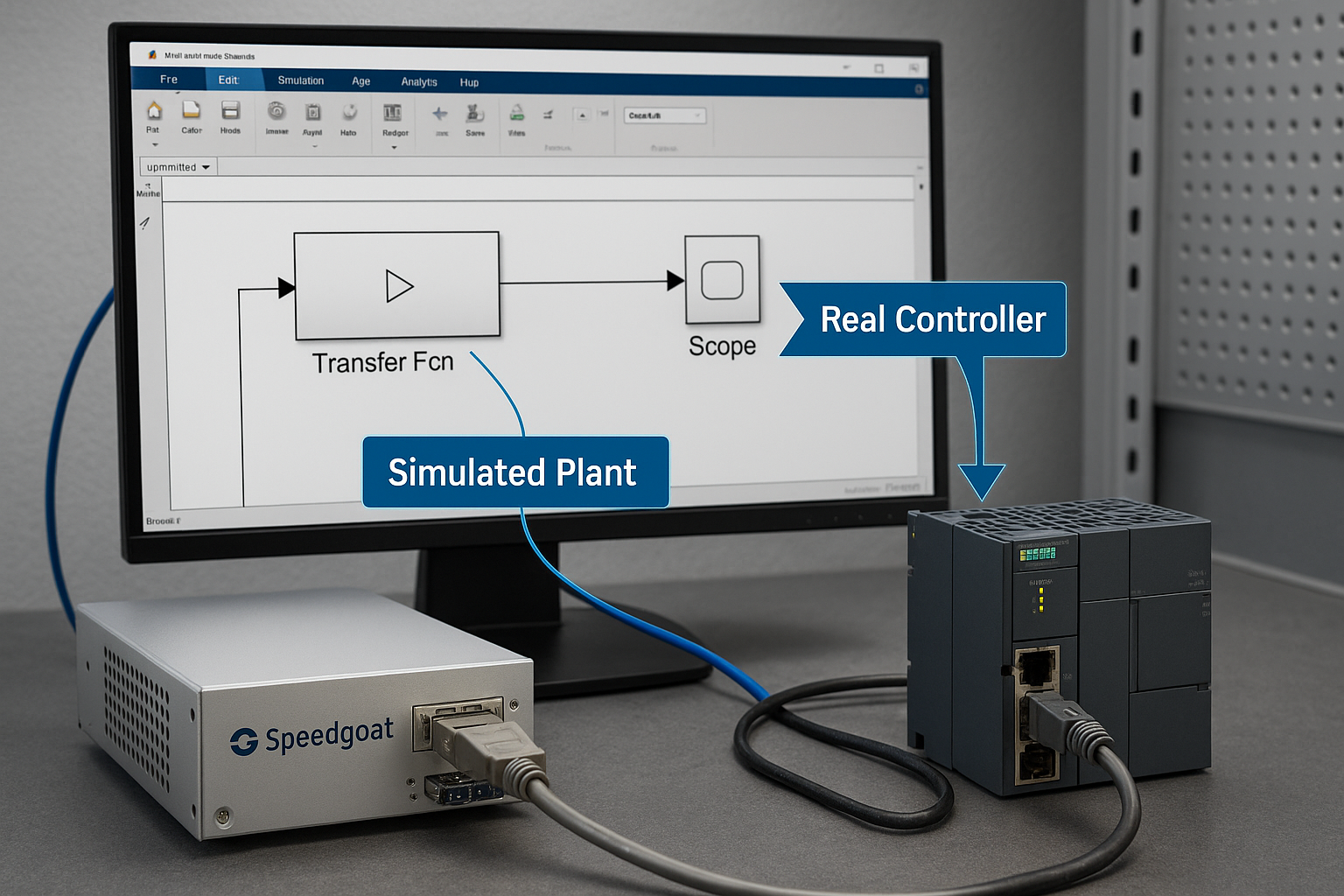

What is Hardware-in-the-Loop (HIL) Simulation?

Hardware-in-the-Loop (HIL) simulation is a real-time testing technique that allows engineers to validate control algorithms against a simulated model of the physical system (the "plant"). This model behaves exactly like the real-world system, allowing for thorough testing without the risks associated with physical hardware.

In a typical HIL setup, the control algorithm runs on actual controller hardware (e.g., a PLC), while the plant model runs on a real-time target computer. These two components communicate via industrial-grade communication protocols such as EtherCAT or PROFINET, simulating real-world interactions.

Key Features of HIL Simulation

- Real-time execution of plant models

- Interaction with physical controllers

- Early error detection

- Safe simulation of extreme conditions

- Multiple iteration capability without hardware wear

By emulating the physical system, HIL simulation enables engineers to verify and fine-tune control logic under virtually any scenario, including those that are dangerous or difficult to replicate physically.

Why MATLAB and Simulink for HIL Simulation?

The combination of MATLAB, Simulink, and Speedgoat target hardware offers a robust, flexible, and efficient solution for HIL simulation. Here's why engineers around the globe trust this setup:

Simulink Real-Time

Simulink Real-Time allows engineers to build real-time applications from Simulink models and run them on Speedgoat target computers. It supports real-time execution and enables rapid prototyping, tuning, and testing.

Simscape and Physical Modeling

Simscape extends Simulink by enabling multi-domain physical system modeling. This allows for accurate simulation of electrical, mechanical, hydraulic, and thermal systems. You can create high-fidelity plant models that reflect the true behavior of the system under test.

Speedgoat Hardware

Speedgoat systems are designed to execute real-time simulations reliably and with low latency. These systems interface seamlessly with Simulink and provide various I/O options, making them ideal for industrial testing environments.

Integration with PLCs

Using tools like Simulink PLC Coder, engineers can generate code from their Simulink models and deploy it directly to industrial PLCs. This streamlines the workflow and ensures consistency between simulation and deployment.

Benefits of HIL Simulation in Industrial Applications

Implementing HIL simulation within an industrial workflow provides numerous advantages over traditional testing methods:

- Cost Efficiency: Simulating faults and iterations does not risk hardware damage, reducing rework costs.

- Risk Reduction: Dangerous conditions can be tested without jeopardizing personnel or machinery.

- Improved Accuracy: Real-time simulations offer precise system behavior that closely mirrors real-world conditions.

- Faster Time to Market: With faster iterations and validation, product development cycles are significantly shortened.

- Enhanced Testing Scope: From normal operation to rare edge cases, HIL simulation can cover all scenarios.

HIL Simulation Workflow Explained

A typical HIL simulation workflow using MATLAB, Simulink, and Speedgoat comprises several stages:

- Develop Control Algorithm: Using Simulink, engineers design and simulate the control logic.

- Create Plant Model:Simscape or other modeling tools are used to develop a physical system model.

- Generate Code: Simulink Coder and Simulink PLC Coder translate models into real-time executable code.

- Deploy Code to Hardware: The plant model is deployed to the Speedgoat target system; the controller logic is sent to a PLC.

- Run Real-Time Simulation: The controller and plant model interact over high-speed communication protocols.

- Monitor and Analyze: Engineers use Simulink dashboards and MATLAB tools to assess performance and make adjustments.

This closed-loop setup provides a complete test bed for control validation, long before actual deployment in the field.

Use Case: Industrial Cooling Fan System

One example from the MathWorks white paper showcases an industrial cooling fan system. Engineers modeled the plant (fan system) using Simulink and Simscape, while the control logic ran on a PLC. The Speedgoat target computer executed the plant simulation in real time, connected via high-speed industrial communication protocols.

This HIL setup enabled engineers to:

- Validate controller response to temperature changes

- Simulate fan failures and observe behavior

- Test communication integrity under load

- Ensure the entire control loop worked flawlessly before field deployment

This approach significantly reduced commissioning time and prevented costly errors.

Protocol Support and Scalability

Simulink Real-Time and Speedgoat systems support a broad range of industrial protocols, including:

- EtherCAT

- PROFINET

- EtherNet/IP

- CAN

- Modbus

This flexibility ensures seamless integration into existing industrial networks and allows testing of a variety of control hardware and configurations.

The scalability of MATLAB and Simulink means that HIL simulation can grow with your project. Whether you're testing a small embedded system or a full-scale industrial process, the same workflow applies.

Summary and Engineering Outlook

Hardware-in-the-Loop simulation is not just a testing strategy; it is a paradigm shift in how control systems are designed, validated, and deployed. By embracing HIL simulation with MATLAB and Simulink, engineers gain unprecedented confidence in their control logic before any hardware is touched.

At Keentel Engineering, we specialize in helping industrial clients implement HIL workflows using

MATLAB, Simulink, Speedgoat, and industry-standard PLCs. Our services include:

- Custom HIL architecture design

- Real-time plant model development

- PLC integration and code deployment

- System validation and performance tuning

Let us help you reduce costs, accelerate timelines, and deploy control systems with confidence.

Ready to get started with HIL simulation?

Contact Keentel Engineering to learn how our simulation and validation services can transform your development process.

Technical FAQs with Answers

What is Hardware-in-the-Loop (HIL) simulation?

HIL simulation is a technique that connects a real controller to a simulated plant running in real-time, enabling engineers to validate control algorithms without physical prototypes.

How does Simulink support HIL simulation?

Simulink offers real-time code generation via Simulink Real-Time, supports physical modeling using Simscape, and integrates with hardware through Speedgoat systems.

What is the benefit of using Speedgoat with Simulink?

Speedgoat hardware is optimized for low-latency, high-speed execution of real-time plant models, enhancing HIL performance and synchronization.

4. Can you simulate extreme conditions using HIL?

Yes. Engineers can simulate vibrations, overheating, deep-sea pressure, or even actuator failures without risking real equipment.

5. Is HIL suitable for high-risk environments like oil rigs or turbines?

Absolutely. These systems benefit most from HIL’s ability to test failure modes before field deployment.

6. How does Simulink PLC Coder work in HIL testing?

It generates structured text code from Simulink models, which can be deployed to industrial PLCs for real-time algorithm testing.

7. What communication protocols does Simulink Real-Time support?

Protocols include EtherCAT®, PROFINET®, EtherNet/IP™, and more for industrial integration.

8. What is Simscape used for in HIL simulation?

Simscape is used to create physics-based models of mechanical, electrical, thermal, and hydraulic systems for realistic plant behavior.

9. Why perform HIL before hardware testing?

To catch design flaws early, reduce rework cost, and avoid hardware damage during validation.

10. Can HIL simulation run in real-time?

Yes, Speedgoat systems execute Simulink-generated code with hard real-time guarantees.

11. What is the difference between desktop and real-time simulation?

Desktop simulation is for development; real-time simulation ensures synchronized interaction with actual controllers.

12. Does HIL simulation work with non-MathWorks controllers?

Yes. As long as communication standards are maintained, you can use external PLCs and controllers.

13. What are the cost savings of using HIL simulation?

Savings stem from reduced hardware iterations, early bug detection, and fewer integration issues.

14. What industries benefit most from HIL?

Aerospace, energy, automotive, industrial automation, and medical device sectors.

15. How accurate are Simscape models in simulating physical systems?

They offer high fidelity due to underlying physics-based modeling principles.

16. Can Keentel Engineering set up HIL systems?

Yes, Keentel specializes in Simulink-based HIL simulation integration with PLCs and industrial targets.

17. How scalable is HIL simulation?

Easily scalable—from small subsystem models to full industrial plants.

18. What testing scenarios can be simulated in HIL?

Voltage surges, sensor failures, actuator stalling, overheating, system faults, and control loop disruptions.

19. Does HIL testing require specialized training?

Familiarity with MATLAB/Simulink and real-time systems is needed—Keentel offers training and support.

20. Is HIL simulation suitable for embedded system development?

Yes. It supports real-time testing of embedded control algorithms in a safe environment.

21. Can real-world sensor inputs be emulated in HIL?

Yes. Inputs such as torque, pressure, or vibration signals can be simulated to test control response.

22. How fast can HIL simulations run?

Real-time speeds depend on model complexity and hardware—Speedgoat can execute sub-ms control loops.

23. Can I run multiple test cases with HIL setup?

Yes. Test suites can automate hundreds of scenarios without changing physical setups.

24. What role does Keentel Engineering play in automation HIL?

Keentel provides consulting, integration, model development, and support services across the full HIL lifecycle.

25. Can HIL simulations reduce time to market?

Absolutely. Faster iterations and safer validation significantly shorten development and deployment timelines.

About the Author:

Sonny Patel P.E. EC

IEEE Senior Member

In 1995, Sandip (Sonny) R. Patel earned his Electrical Engineering degree from the University of Illinois, specializing in Electrical Engineering . But degrees don’t build legacies—action does. For three decades, he’s been shaping the future of engineering, not just as a licensed Professional Engineer across multiple states (Florida, California, New York, West Virginia, and Minnesota), but as a doer. A builder. A leader. Not just an engineer. A Licensed Electrical Contractor in Florida with an Unlimited EC license. Not just an executive. The founder and CEO of KEENTEL LLC—where expertise meets execution. Three decades. Multiple states. Endless impact.

Services

Let's Discuss Your Project

Let's book a call to discuss your electrical engineering project that we can help you with.

About the Author:

Sonny Patel P.E. EC

IEEE Senior Member

In 1995, Sandip (Sonny) R. Patel earned his Electrical Engineering degree from the University of Illinois, specializing in Electrical Engineering . But degrees don’t build legacies—action does. For three decades, he’s been shaping the future of engineering, not just as a licensed Professional Engineer across multiple states (Florida, California, New York, West Virginia, and Minnesota), but as a doer. A builder. A leader. Not just an engineer. A Licensed Electrical Contractor in Florida with an Unlimited EC license. Not just an executive. The founder and CEO of KEENTEL LLC—where expertise meets execution. Three decades. Multiple states. Endless impact.

Leave a Comment

We will get back to you as soon as possible.

Please try again later.