A Coordinated Electric System Interconnection Review—the utility’s deep-dive on technical and cost impacts of your project.

Challenge: Frequent false tripping using conventional electromechanical relays

Solution: SEL-487E integration with multi-terminal differential protection and dynamic inrush restraint

Result: 90% reduction in false trips, saving over $250,000 in downtime

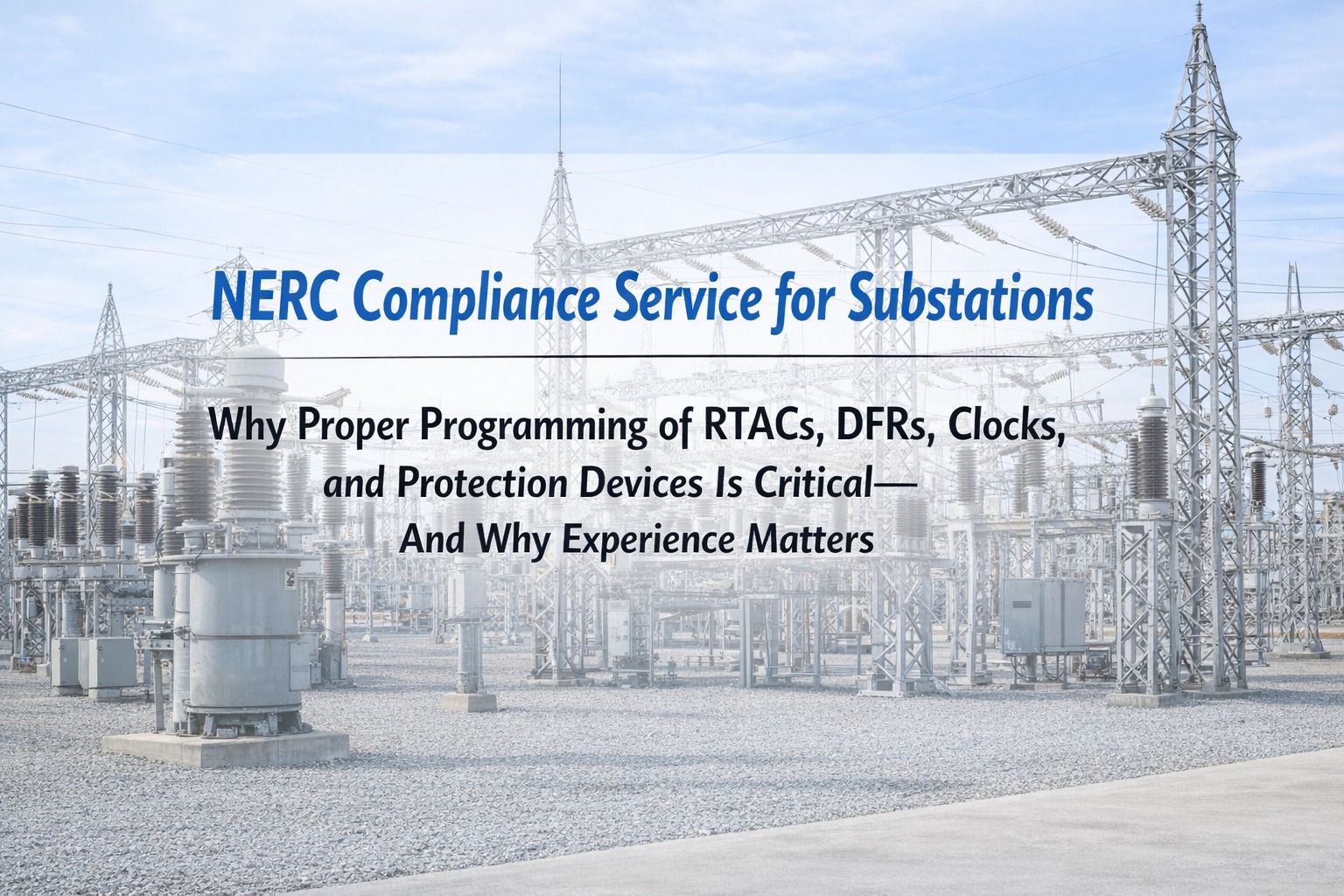

Building the Backbone of Energy: 18 Essential Studies Every Substation Engineer Must Master

July 28, 2025 | Blog

Introduction: The Invisible Infrastructure That Powers Our Lives

Substations rarely get the spotlight. They're not sleek. They're not fast. They’re not the kind of “smart” consumers rave about. But without them? The grid collapses. Substations are the quiet custodians of energy reliability, serving as the backbone of transmission and distribution systems.

In the era of rooftop solar, grid decarbonization, EV charging, and distributed generation, substation engineering is more than cables and control rooms—it’s about designing resilience.

At

Keentel Engineering, our engineers don't just build substations—we design for long-term uptime, safety, and operational certainty. Below are 18 foundational substation engineering studies that transform raw land into a fully functional and future-proof grid asset.

1. Short-Circuit Study

Purpose: Analyze fault current behavior.

Outcome: Ensures breakers, switches, and relays survive and isolate faults.

Insight:

Faults are inevitable. Survival is engineered.

2. Load Flow Study

Purpose: Model how electricity flows through the system.

Outcome: Prevents voltage drops, equipment overloading, and inefficiency.

Insight: Power flows where it’s easiest—you must guide it.

3. Insulation Coordination Study

Purpose: Select appropriate Basic Insulation Level (BIL).

Outcome: Protection from switching and lightning surges.

Insight: Overdesigning is costly. Under-designing is catastrophic.

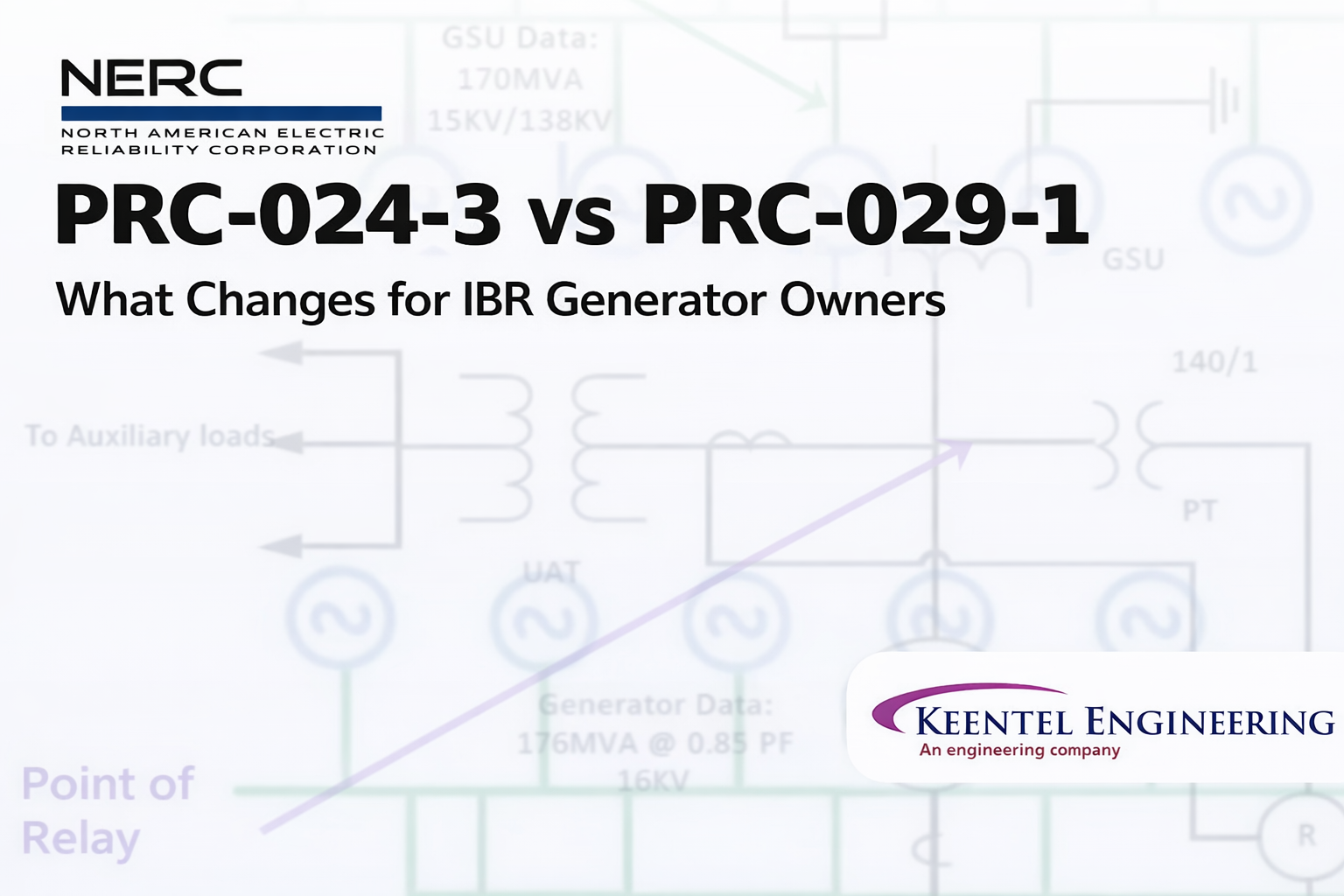

4. Protection and Control Analysis

Purpose: Coordinate relays, SCADA, and breaker operations.

Outcome: Seamless isolation of faults with minimal service disruption.

Insight: Protecting uptime is harder than protecting equipment.

5. DC System Battery Calculations

Purpose: Ensure control power stays live during outages.

Outcome: Reliable operation of relays and switchgear during emergencies.

Insight: The DC system is your last line of control.

6. AC Auxiliary Transformer Calculations

Purpose: Size transformers for lighting, HVAC, and pumps.

Outcome: Operational comfort and safety systems stay functional.

Insight: Even your backup systems need backup.

7. Ground Grid Study

Purpose: Protect personnel from dangerous step and touch voltages.

Outcome: Safe fault current dissipation into earth.

Insight: Grounding isn't just safety—it’s life preservation.

8. Lightning Protection Calculations

Purpose: Properly position shield wires and masts.

Outcome: Reduce the impact of direct lightning strikes.

Insight: Lightning is a certainty. Mitigate accordingly.

9. Lighting Calculations

Purpose: Maintain safe visibility for maintenance and inspections.

Outcome: Compliance with utility codes and improved site security.

Insight: Visibility = safety. Never compromise on lighting.

10. Voltage Drop Calculations

Purpose: Ensure voltage stays within equipment tolerances.

Outcome: Proper conductor sizing.

Insight: Every wire is a resistor in disguise.

11. Conduit Fill Calculations

Purpose:

Avoid mechanical stress on cables.

Outcome:

Accurate conduit sizing and pulling methodology.

Insight: Friction is the silent destroyer of cables.

12. Land Survey and Site Grading Analysis

Purpose:

Verify elevation, slope, and drainage feasibility.

Outcome:

Prevents water accumulation and structural issues.

Insight: A site is only as good as its grading.

13. Geotechnical Investigation & Foundation Calculations

Purpose:

Assess soil strength, moisture, and type.

Outcome:

Foundation that withstands time and environmental stress.

Insight:

You can’t cheat gravity. Foundations must match the soil.

14. Structural Steel Calculations

Purpose: Design safe and code-compliant support structures.

Outcome: Stability under wind, seismic, and conductor tension loads.

Insight: Steel fatigue isn’t visible—until failure.

15. Bus Calculations

Purpose:

Size and support high-current bus conductors.

Outcome:

Avoids flexing, overheating, or structural collapse.

Insight: Buses move power—and momentum.

16. Transformer Noise Calculations

Purpose: Keep noise below regulatory and residential limits.

Outcome:

Quieter substations using sound walls or low-noise transformers.

Insight:

Neighbors don't hear decibels—they hear complaints.

17. Harmonic Analysis

Purpose: Identify and mitigate waveform distortion.

Outcome:

Cleaner power for sensitive equipment.

Insight: Non-linear loads require proactive design.

18. Fire Protection Study

Purpose: Design mitigation for worst-case scenarios.

Outcome: Suppression systems, fire-rated walls, and safety zones.

Insight: Substations rarely burn—but when they do, it’s devastating.

The Bigger Picture: Beyond Steel and Schematics

Each engineering study above isn’t just a formality—it’s a layer of foresight, safety, and operational resilience. At Keentel Engineering, we don’t just design substations—we engineer reliability that scales with the evolving needs of today’s power grid.

Yes, we calculate in kilovolts, impedance, and microseconds.

But we also engineer for:

- Grid uptime during extreme events

- Safety margins that save lives

- Investor-grade performance for decades of trust

This mindset shapes our work on every substation—from rural step-down stations to high-voltage transmission hubs. Our engineers treat every study not just as a task—but as a responsibility to the communities and clients we serve.

When you choose Keentel, you're not just checking boxes. You're building a grid asset that performs, endures, and earns confidence.

Explore our services:

Frequently Asked Questions (FAQs)

1. Why do substations require so many studies before construction?

Each study addresses a unique risk to grid reliability, personnel safety, or equipment performance. Skipping one is like launching a flight without pre-checks.

2. How often should short-circuit studies be updated?

Typically every 5 years, or after any major equipment addition, topology change, or capacity upgrade.

3. Can software automate all substation studies?

Software like ETAP or SKM Power Tools helps, but engineering judgment is irreplaceable for interpretation and validation.

4. What's the most common mistake in substation planning?

Assuming the grid won’t change. Overdesign today is cheaper than retrofitting tomorrow.

5. How does a load flow study affect relay settings?

It informs overcurrent relay pickups, transformer tap positions, and capacitor bank sizing.

6. Why is insulation coordination more than surge arresters?

It considers clearances, BIL ratings, and voltage transients to ensure insulation withstands worst-case conditions.

7. What is BIL in simple terms?

Basic Insulation Level (BIL) is like electrical armor—designed to absorb lightning and switching surges.

8. How is the grounding grid designed?

By using soil resistivity tests, fault current levels, and touch/step potential thresholds. Tools like CDEGS are standard.

9. Why is the DC control system so critical?

It ensures protection relays, breaker controls, and communications work during outages when AC power is unavailable.

10. Can we use solar or UPS instead of DC batteries?

DC batteries are stable, predictable, and regulated for grid operations. Solar and UPS add complexity.

11. Do all substations require harmonic analysis?

Only those with non-linear loads (e.g., VFDs, UPS) or those connected to industrial/renewable systems.

12. How loud is a typical substation transformer?

Standard units produce 60–70 dB. Low-noise models reduce this to 50 dB or lower.

13. What’s the acceptable voltage drop?

Generally <10% for DC and <5% for AC systems to avoid underperformance.

14. Why grade land even if it looks flat?

Because flat ≠ drained. Poor drainage leads to water pooling, erosion, and unsafe foundations.

15. Can harmonic filters fail?

Yes—due to overloading, component wear, or detuning. Regular maintenance is essential.

16. How are substation lighting levels specified?

In foot-candles. Most utility codes require 2–5 foot-candles at 3 feet above ground.

17. Why are conduit fill limits important?

Overfilling causes cable overheating, difficult pulls, and long-term insulation damage.

18. Is transformer fire risk real?

Absolutely. Especially oil-filled units in urban areas. Firewalls and suppression are mandatory.

19. Are both civil and electrical engineers needed?

Yes. Substations involve grading, drainage, foundation, steel, and electrical integration.

20. What’s the most overlooked design risk?

Transformer noise. Ignored until neighbors complain.

21. How deep are ground rods driven?

Typically 10–40 feet, based on soil resistivity and fault current dissipation needs.

22. Can a substation design be relocated?

Only partially. Grounding, grading, and foundation studies are highly site-specific.

23. Do all utilities follow the same standards?

No. Standards vary by ISO, RTO, or utility-specific criteria.

24. Why is relay coordination so complex?

Relays must protect assets while coordinating with upstream/downstream devices across the grid.

25. What’s the maximum acceptable harmonic distortion?

IEEE 519 recommends <5% Total Harmonic Distortion (THD).

26. Who validates substation design compliance?

Utility reviewers, independent engineers, and often state or federal regulators.

27. What tools are used for substation studies?

We use ETAP, SKM, CYME, PSCAD, RISA-3D, CDEGS, and AutoCAD.

28. Are these studies needed for renewable energy plants too?

Yes—especially grounding, load flow, harmonic analysis, and protection coordination.

29. How long does a full substation study package take?

Anywhere from 3 to 6 months, depending on site complexity and scope.

30. What makes Keentel Engineering different in substation design?

We don’t check boxes. We design for what might go wrong tomorrow, not just for what works today.

About the Author:

Sonny Patel P.E. EC

IEEE Senior Member

In 1995, Sandip (Sonny) R. Patel earned his Electrical Engineering degree from the University of Illinois, specializing in Electrical Engineering . But degrees don’t build legacies—action does. For three decades, he’s been shaping the future of engineering, not just as a licensed Professional Engineer across multiple states (Florida, California, New York, West Virginia, and Minnesota), but as a doer. A builder. A leader. Not just an engineer. A Licensed Electrical Contractor in Florida with an Unlimited EC license. Not just an executive. The founder and CEO of KEENTEL LLC—where expertise meets execution. Three decades. Multiple states. Endless impact.

Services

Let's Discuss Your Project

Let's book a call to discuss your electrical engineering project that we can help you with.

About the Author:

Sonny Patel P.E. EC

IEEE Senior Member

In 1995, Sandip (Sonny) R. Patel earned his Electrical Engineering degree from the University of Illinois, specializing in Electrical Engineering . But degrees don’t build legacies—action does. For three decades, he’s been shaping the future of engineering, not just as a licensed Professional Engineer across multiple states (Florida, California, New York, West Virginia, and Minnesota), but as a doer. A builder. A leader. Not just an engineer. A Licensed Electrical Contractor in Florida with an Unlimited EC license. Not just an executive. The founder and CEO of KEENTEL LLC—where expertise meets execution. Three decades. Multiple states. Endless impact.

Leave a Comment

We will get back to you as soon as possible.

Please try again later.

Related Posts