As extreme winter events become more frequent and severe, the reliability of generating units during cold weather is no longer a seasonal afterthought—it’s a mission-critical mandate. At Keentel Engineering, we emphasize a proactive, standards-based approach to winterizing power generation assets. Based on the NERC Reliability Guideline Version 4 (June 2023), we highlight best practices and operational strategies to safeguard power system stability through winter’s most punishing extremes.

Why Winter Readiness Matters

Cold weather can severely degrade power generation capacity, from frozen instrumentation and disrupted fuel supply to full unit trips. These risks were starkly illustrated during major winter outages in Texas (2021), South Central U.S. (2018), and elsewhere. The fallout includes not just loss of power but also cascading impacts on grid reliability, public safety, and economic stability.

To counteract this, NERC’s latest guideline outlines a framework for developing a cold weather readiness program across conventional and inverter-based resources (IBRs).

Key Program Elements for Winter Readiness

1. Safety First

Safety protocols must be embedded into all phases of winter preparation. Job Safety Analyses (JSAs), personal protective gear, anti-slip provisions, and travel protocols are essential for personnel safety during snow, ice, and low visibility events.

2. Defined Management Roles

From senior executives to plant managers:

- Senior leadership must set clear expectations and champion readiness efforts.

- Plant managers should develop tailored cold weather procedures and oversee annual readiness reviews and staff training.

3. Cold Weather Preparation Procedures

Winter readiness involves:

- Annual preventive maintenance

- Inspections of critical components

- Adjusting operating timelines before first frost

- Decommissioning freeze protection post-season

4. Evaluating Critical Components

Freeze-vulnerable elements include:

- Instrument air systems

- Pressure/flow/level transmitters

- Fuel handling systems

- Lubrication and backup power systems

- Heat tracing, insulation, heaters, and ventilation controls

5. Testing Emergency and Backup Systems

Regular testing of:

- Auxiliary boilers

- Black start generators

- Fire pumps

- Secondary fuel systems

6. Targeted Training Programs

Annual cold-weather training must cover:

- Equipment freeze points

- Alarm response

- Fuel switching protocols

- Use of portable heaters

- Communication protocols during emergencies

7. Enhanced Communication

Coordination with Reliability Coordinators, Balancing Authorities, and Transmission Operators ensures the grid ecosystem is aware of unit status, derates, or failures.

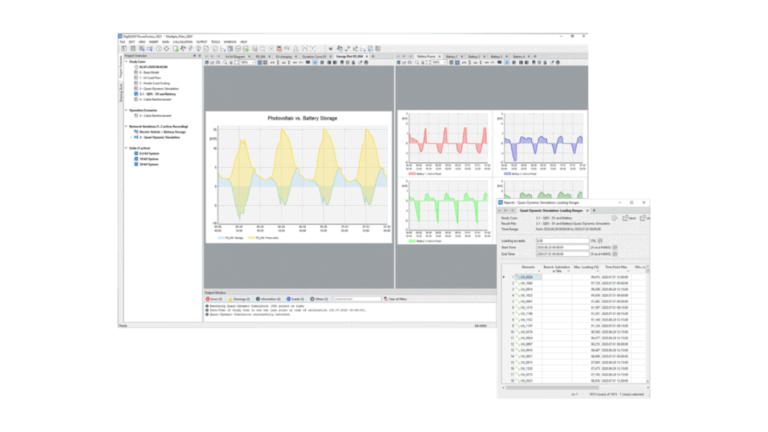

Winterization for Inverter-Based Resources (IBRs)

Special considerations apply to wind, solar, and battery-based systems:

- Nacelle heaters, antifreeze for liquid cooling

- Anemometer reliability

- Road access and de-icing protocols

- Battery thermal management

Lessons Learned from Past Cold Events

Numerous case studies and FERC/NERC post-event reports underscore the need for:

- Plant operator training

- Adequate fuel planning

- Equipment insulation

- Instrument calibration and freeze protection

- Interdependent fuel and electricity contingency planning

Metrics & Continuous Improvement

Per FERC guidance, effectiveness is measured via:

- Reliability reports

- Industry surveys

- Lessons learned from event analyses

Keentel Engineering integrates these metrics into our winter readiness audits, program development, and asset-specific engineering services.

Winter Weather Readiness FAQs

1. Why is cold weather readiness important for generating units?

Cold temperatures can freeze critical generator components, leading to partial or full outages and compromising grid reliability and operational safety.

2. Is winter weather preparation mandatory under NERC?

While not a formal NERC Standard, winter readiness is strongly recommended and supports risk-based NERC compliance frameworks.

3. Which power systems are most vulnerable to winter conditions?

Both conventional generators and inverter-based resources (IBRs) — such as wind, solar, and batteries — face distinct risks from freezing conditions.

4. What is the role of management in cold weather preparation?

Management must allocate resources, implement policies, and ensure that winterization plans and training programs are enforced and reviewed annually.

5. What is heat tracing and why is it critical?

Heat tracing involves electric cables wrapped around equipment or piping to prevent freezing — a key element in TOV and outage prevention.

6. Which components need to be winterized in a power generator?

Essential systems include sensors, pumps, valves, lubrication systems, and fuel supply components.

7. What causes cold weather outages in conventional plants?

Common causes include ice accumulation in sensing lines, frozen valves, blocked fuel supply lines, and motor failure due to viscosity issues in lubricants.

8. How is winter prep different for wind, solar, and battery systems (IBRs)?

These require de-icing systems, antifreeze cooling, heated inverters, and battery thermal protection strategies.

9. What is a readiness review and why perform one?

A winter readiness review ensures all procedures and upgrades are complete — identifying overlooked weak points before the first cold front.

10. How does NERC monitor winter readiness across the industry?

NERC collects data through readiness surveys, post-event reports, and coordination with Balancing Authorities and plant operators.

11. What training is required for cold weather events?

Staff should learn alarm response, freeze-point identification, portable heater protocols, and lessons from past cold-weather failures.

12. How do you test heat tracing systems for functionality?

Check circuit continuity, amperage draw, controller response, and insulation condition before winter begins.

13. What are warning signs of winter-related equipment failure?

Look for erratic sensor readings, repeated alarms, fuel interruptions, or full unit trips — all signs of insufficient insulation or freezing.

14. How often should emergency generators be tested for winter readiness?

Test before each winter season and again before any forecasted severe weather event.

15. How does insulation failure affect operations?

Poor insulation allows ambient cold to reach critical systems, causing frozen lines, misread sensors, and unsafe shutdowns.

16. What are some field-tested winterization best practices?

Use tarps, wind barriers, enclosures, portable heaters, and on-site storage for backup fuel or antifreeze chemicals.

17. How do I report winter readiness status to grid operators?

Use structured coordination channels with your Balancing Authority, Transmission Operator, and Reliability Coordinator.

18. What’s the protocol after a winter-induced outage or trip?

Conduct a root cause analysis, then update your cold weather readiness procedures based on lessons learned.

19. Can portable heaters cause electrical issues?

Yes — ensure circuits can handle load, and monitor GFCI devices for trips caused by condensation or moisture.

20. How does Keentel Engineering support generating units in winter?

We provide tailored site assessments, freeze protection design, emergency system audits, and winterization plans for both conventional and IBR systems.

Read NERC’s official Winter Weather Readiness Guideline for comprehensive technical standards.

Ready to Prepare Your Grid for Winter?

Keentel Engineering helps you proactively winterize your generation fleet with:

- Cold weather engineering audits

- Custom winter procedures for both conventional and IBR systems

- Backup system evaluation and insulation design

Explore Keental Services or Contact Us Today to begin your cold weather readiness journey.