As solar photovoltaic (PV) installations grow in capacity and global coverage, effective operation and maintenance (O&M) becomes essential for reliability, safety, and performance. Keentel Engineering embraces the climate-specific O&M best practices outlined by the International Energy Agency’s (IEA) PVPS Task 13, ensuring solar assets operate efficiently regardless of location.

Why Climate-Specific PV O&M Matters

The performance of PV systems varies dramatically across seven key climate zones: temperate, hot and dry, hot and humid, high-altitude desert, flood-prone, cyclonic, and snowy regions. Keentel integrates O&M strategies tailored to these zones, recognizing unique challenges like:

- Soiling and thermal stress in deserts.

- Corrosion and vegetation overgrowth in humid areas.

- Structural threats from snow loads or high winds.

- Water damage and debris in flood-prone sites. Each condition requires proactive planning—from cleaning protocols to structural reinforcements and emergency procedures.

Key O&M Elements Delivered by Keentel

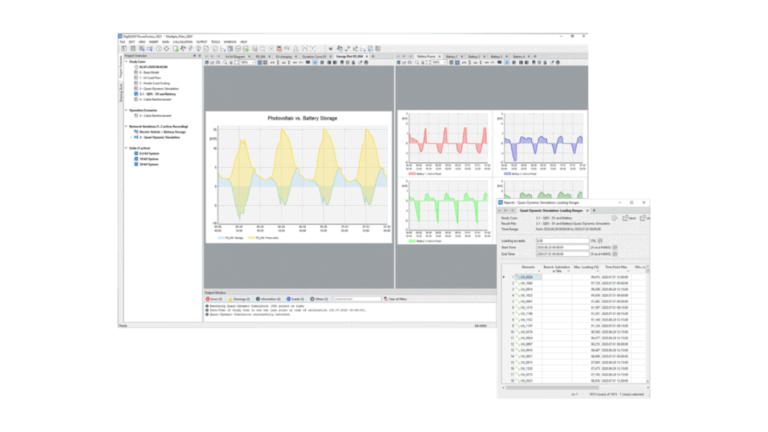

1. Monitoring and Performance Analytics

Using IEC 61724-1 Class A monitoring standards, Keentel offers:

- Real-time performance dashboards.

- Alarm notifications for rapid response.

- Predictive analytics using AI and digital twins.

- Satellite and sensor-based irradiance modeling.

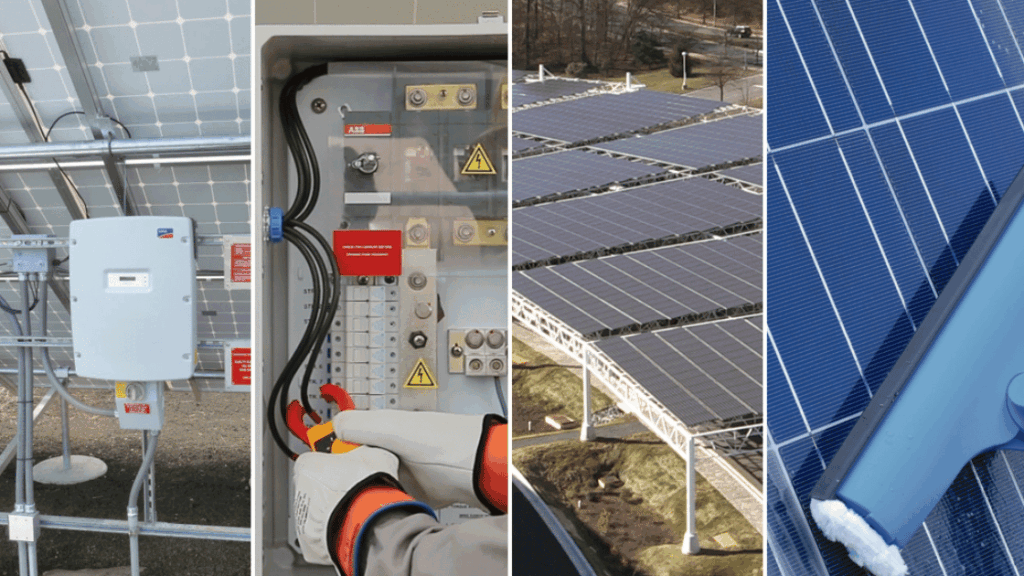

2. Preventive and Corrective Maintenance

Keentel tailors PM and CM schedules based on:

- Temperature variations and rainfall trends.

- Soiling loss indexes.

- Vegetation growth rates.

- Manufacturer-specific component guidelines. Specialized tools like aerial IR thermography, EL imaging, and IV curve tracing allow precise diagnostics with minimal disruption.

3. Forecasting and Grid Compliance

Our O&M services include:

- PV power generation forecasts (short, medium, long-term).

- Grid-compliant control strategies (voltage/frequency support, PF management).

- Integration with utilities and energy traders using NWP, satellite, and machine learning models.

4. Safety and Risk Management

Keentel ensures:

- Full adherence to ISO 45001, ISO 9001, and IEC 63049.

- Lockout-tagout (LOTO) and PPE protocols.

- Site-specific emergency response plans.

- Fire, flood, and wildlife safety measures.

Customized O&M for All Climate Zones

Moderate (Temperate)

- Emphasis on vegetation and wildlife control.

- Selective cleaning based on industrial fallout or bird droppings.

Hot & Dry

- Wildlife safety, anti-venom kits, and hydration strategies.

- Frequent inspection for UV and sand damage.

High-Altitude Desert

- Wind-blown dust and thermal stress mitigation.

- High-durability cabling and racking.

Hot & Humid

- Rodent and termite-proof cabling.

- Enhanced ventilation for inverters.

Flood-Prone

- Elevating electrical components.

- Procedures for preemptive shutdown and post-flood inspections.

Cyclonic

- Wind tunnel-tested racking, reinforced mounts.

- Storage of spare modules and connectors.

Snowy

- Steel racking preferred over aluminum.

- Controlled heating and manual snow removal protocols.

Why Choose Keentel Engineering?

With 30 years of power system experience and global best practices, Keentel:

- Enhances PV plant performance with contract-defined KPIs.

- Ensures 99%+ uptime through preventive strategies.

- Guarantees bankability by reducing investment risk.

- Supports regulatory compliance across ISO, IEC, and utility codes.

Explore Our Utility-Scale Solar Services

FAQs About PV O&M

What is the Performance Ratio (PR) in PV systems?

PR is the ratio of actual AC energy output to theoretical output under STC. It accounts for all system losses including modules, inverters, and wiring.

How does Keentel correct PR for temperature?

We apply a linear temperature correction using module temperature coefficients to ensure accurate, climate-adjusted performance tracking.

What is Soiling Ratio (SR)?

SR measures power loss due to dirt accumulation. Keentel calculates SR using both power output and short-circuit current comparisons.

Does Keentel offer predictive maintenance?

Yes, leveraging AI and digital twin technologies, we detect early-stage failures and optimize component replacement timelines.

What are the most common climate-specific O&M actions?

From anti-corrosion in humid zones to snow load mitigation and wind-load inspections, O&M varies by location and weather profile.

What safety standards does Keentel follow?

Our operations comply with ISO 45001 (safety), ISO 9001 (quality), and IEC 63049 (PV system O&M standards).

How is plant availability measured?

We use both time-based and energy-based KPIs, targeting availability thresholds of 99% or higher.

How do you handle plant shutdowns in flood zones?

We initiate preemptive shutdowns and post-event inspections for insulation failures, structural damage, and water ingress.

What monitoring class is used for large PV plants?

IEC 61724-1 Class A monitoring ensures high-accuracy diagnostics and real-time performance visibility.

Are sky imagers used for forecasts?

Yes. We utilize sky imagers for highly localized short-term forecasts (10–30 minutes) during rapidly shifting weather.

How is vegetation managed in moderate climates?

Routine grass trimming combined with module inspections helps prevent shading, soiling, and pest interference.

What are the typical costs of O&M?

Base O&M: €6.5–€16.5/kWp/year. Advanced diagnostics (e.g., thermal scans): €0.5–€3/module.

What forecasting models are used?

We use NWP models (e.g., ECMWF), satellite motion tracking, and hybrid AI algorithms such as ANN and SVM.

Do you ensure grid code compliance?

Yes. Our plant control systems (PPCs) deliver voltage, frequency, and reactive power support per utility standards.

Is your data SCADA-integrated?

All inverter, sensor, and alarm data streams are integrated into SCADA platforms with web and mobile dashboards.

What kind of spares management is offered?

We stock critical onsite spares and coordinate with OEM vendors to enable rapid part replacement.

How is snow load managed?

We use structural reinforcements, manual brushing, and electrical heating via reverse current methods.

Do you manage warranties?

Yes. We manage OEM coordination and warranty claims for modules, inverters, and balance-of-system components.

What kind of training do your staff receive?

Our electricians are certified in PV-specific safety, high-voltage handling, and emergency response protocols.

Can you retrofit older plants to meet new grid codes?

Yes. We offer PPC upgrades, firmware installations, and hardware replacements for compliance.

How is real-time fault detection achieved?

Using Class A monitoring with AI-powered analytics and threshold-based alarms for quick diagnostics.

How is energy yield loss calculated during outages?

We calculate MWh lost based on irradiance-adjusted performance models during each downtime event.

What is the Energy Performance Index (EPI)?

EPI benchmarks actual energy yield against a contractual baseline, often used with PR for performance assurance.

Can I monitor my plant performance remotely?

Yes. Our secure web and mobile platforms allow 24/7 access to real-time analytics and alarms.

What support do you offer during cyclones?

We perform pre-storm inspections, reinforce mounts, stock critical spares, and conduct full post-event assessments.

Keentel Engineering offers advanced solar operation and maintenance services tailored for all climates, ensuring high performance, safety, and grid code compliance.

Explore the IEA PVPS Task 13 O&M Guidelines for international best practices in climate-specific solar maintenance.

Contact Us to discuss a tailored PV O&M strategy for your region.