As inverter-based resources (IBRs)—such as solar, wind, and battery energy storage systems (BESS)—play a pivotal role in the modern grid, the responsibilities of Generator Owners (GOs) have evolved in alignment with IEEE Std 2800™-2022. This standard sets forth critical guidelines to ensure the safe, stable, and interoperable integration of IBRs with transmission systems. At Keentel Engineering, we specialize in guiding clients through IEEE 2800 compliance from design through verification.

What Is IEEE Std 2800™-2022?

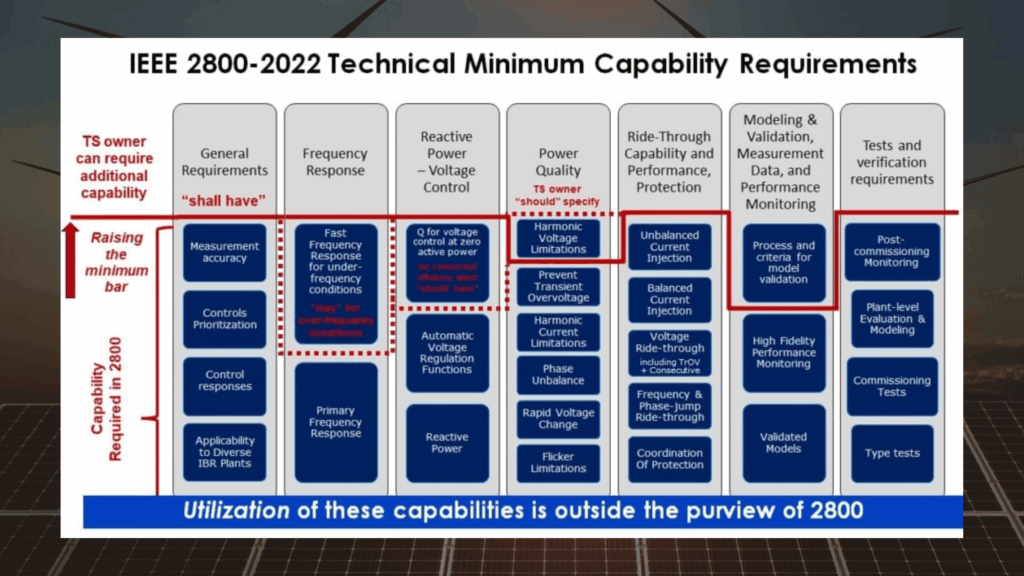

IEEE Std 2800 defines uniform technical minimum requirements for the interconnection, capability, and performance of inverter-based resources connected to transmission and sub-transmission systems. It ensures power system reliability as we transition from synchronous to inverter-dominated grids.

Why It Matters to Generator Owners

For IBR GOs, compliance with IEEE 2800 is not just about regulatory adherence—it’s about engineering a system that ensures safety, stability, and interoperability with transmission networks. The standard outlines both capability and performance requirements that directly influence engineering design, modeling, testing, and operations.

Key Engineering Responsibilities for IBR Generator Owners (IEEE Std 2800™-2022)

As part of meeting IEEE Std 2800™-2022 compliance, inverter-based resource (IBR) Generator Owners (GOs) must undertake a comprehensive set of engineering responsibilities to ensure safe, stable, and interoperable integration with the transmission system.

1. Conformance at the Reference Point of Applicability (RPA)

GOs must ensure that their facility meets IEEE 2800 performance criteria at the RPA—typically the Point of Interconnection (POI) or Point of Measurement (POM). This includes validating voltage, frequency, and power quality performance under both normal operating conditions and grid disturbances.

2. Reactive Power and Voltage Control Compliance

IBR plants must:

- Provide continuous reactive power support

- Operate in voltage control modes such as constant voltage, constant reactive power, or voltage-reactive droop control

GOs are responsible for specifying and tuning inverter control systems to maintain voltage stability dynamically in response to grid changes.

3. Active Power and Frequency Response

Engineering teams must ensure:

- Primary Frequency Response (PFR) is configured to respond to frequency deviations

- Fast Frequency Response (FFR) is enabled for millisecond-level response after disturbances

This involves careful design of control loops and sufficient energy reserves in the battery energy storage system (BESS) or IBR platform.

4. Voltage and Frequency Ride-Through (VRT)

IBR systems must remain connected and support the grid during abnormal events. Generator Owners must:

- Configure controllers to ride through voltage/frequency sags and surges

- Prevent unnecessary tripping

- Coordinate VRT performance with the system protection scheme

5. Power Quality Assurance

To maintain compliance with IEEE 2800 power quality standards, GOs must:

- Conduct harmonic distortion and flicker analysis

- Integrate mitigation solutions like filters if needed

- Verify inverter firmware meets harmonic suppression limits

6. Robust Protection Scheme Engineering

Protection systems must safeguard both plant and grid. GOs must implement:

- Over/under voltage and frequency protections

- ROCOF (Rate of Change of Frequency) detection

- Anti-islanding schemes

- AC overcurrent protection

7. Modeling and Verification Deliverables

Accurate modeling is essential for approval by RTOs and ISOs. Generator Owners must provide:

- Steady-state and dynamic models (PSS®E, PSCAD™, EMT)

- Measurement and benchmark data for model validation

- Documented conformance testing aligned with interconnection studies

8. Grounding and Isolation Coordination

Facilities must include proper isolation devices and integrate with transmission system grounding in accordance with utility safety standards—especially during fault conditions and maintenance outages.

9. Ongoing Compliance and Upgrade Readiness

Compliance with IEEE Std 2800 is not a one-time event. GOs must:

- Maintain compliance throughout the operational lifecycle

- Revalidate plant capability after repowering, controller updates, or significant equipment changes

Benefits of IEEE 2800™-2022 Compliance for IBR Generator Owners

Adhering to IEEE 2800 compliance standards offers more than just regulatory alignment—it enables IBR Generator Owners to build safer, more resilient, and utility-ready energy systems. Here’s how compliance delivers measurable value:

1. Enhanced Grid Stability

Meeting the IEEE 2800 performance criteria ensures your inverter-based resource (IBR) operates harmoniously with the bulk power system. Proper voltage, frequency, and ride-through behavior prevents disruptions during grid faults or transients—promoting overall grid stability.

2. Smoother Market Interconnection and Access

Full compliance aligns with most RTO/ISO interconnection requirements, including those set by PJM, CAISO, ERCOT, and others. This facilitates faster approvals, reduces rework during interconnection studies, and minimizes delays in project energization.

3. Improved Operational Reliability

Well-engineered IBR systems are less prone to nuisance trips, harmonics issues, or frequency instability. This ensures steady output, minimal downtime, and higher system availability across varying load and fault conditions.

4. Legal and Regulatory Risk Reduction

Documented adherence to IEEE 2800 protects Generator Owners during audits, interconnection disputes, and insurance claims. Demonstrating that your facility meets or exceeds the national standard helps mitigate legal and financial liabilities.

5. Long-Term Asset Performance

By following IEEE 2800 throughout the IBR lifecycle—from commissioning to upgrades—operators maintain optimal performance, reducing unexpected failures and prolonging equipment life.

Our Service POI Interconnection Engineering Support

How Keentel Engineering Supports IBR Generator Owners with IEEE 2800™ Compliance

We provide end-to-end engineering and compliance services to help IBR Generator Owners meet the rigorous technical requirements of IEEE Std 2800™-2022. Our multidisciplinary team brings decades of power systems expertise, ensuring that your renewable energy or hybrid facility is grid-ready, compliant, and resilient.

Our IEEE 2800 compliance services include:

IBR Plant Engineering & Design

We support initial design, control architecture, and interconnection layout to ensure compliance from the ground up.

Reactive Power and Frequency Response Tuning

Our engineers fine-tune inverter control systems to meet fast frequency response (FFR), primary frequency response (PFR), and reactive support obligations.

Protection Scheme Engineering

We develop fault ride-through, anti-islanding, and ROCOF-compliant protection strategies that align with both IEEE 2800 and utility-specific interconnection rules.

Dynamic Modeling and Validation

Using PSSE, PSCAD, and EMT-based simulation, we create accurate steady-state and transient models validated against field test data.

Testing and Conformance Documentation

We conduct onsite and lab-based performance testing and prepare fully traceable documentation for ISO/RTO review and sign-off.

Interconnection Studies and Regulatory Support

We prepare modeling files, reports, and submission packages required by RTOs/ISOs—helping clients navigate CAISO, PJM, ERCOT, and FERC compliance milestones.

Final Thoughts

The IEEE Std 2800™-2022 represents a pivotal advancement in inverter-based resource integration. Generator Owners must take a proactive engineering role in meeting these stringent technical requirements to ensure their projects are not only compliant but also optimized for performance and reliability.

Let Keentel Engineering be your trusted partner in building and certifying compliant, future-ready IBR plants.

Call: (813) 389-7871

Email: contact@keentelengineering.com

Visit: www.keentelengineering.com

FAQs for IEEE Std 2800 Compliance for IBR Generator Owners

General

What is IEEE Std 2800-2022?

It is a standard that defines interconnection and interoperability requirements for inverter-based resources (IBRs) with transmission systems.

Who needs to comply with IEEE 2800?

Generator Owners (GOs) of transmission-connected solar, wind, battery storage, and hybrid IBR plants.

When does IEEE 2800 compliance apply?

Upon new interconnection requests or significant modifications (e.g., repowering) of existing IBR plants, as determined by the governing interconnection authority.

Capability & Performance

What is the difference between a capability and a performance requirement?

Capability refers to a function the plant must be able to perform. Performance defines how well it must execute that function.

Does IEEE 2800 specify utilization of functions?

No, utilization (whether and when a function is activated) is determined by the grid operator or interconnection agreement.

Are synchronous generators or FACTS devices covered?

No, only inverter-based resources such as PV, BESS, wind (DFIG, full converter) are covered.

Reactive Power and Voltage Control

What reactive power capabilities are required?

Continuous operation with dynamic reactive support based on grid voltage, with modes like voltage control, power factor control, and droop control.

Is reactive power compensation equipment allowed?

Yes, supplemental IBR devices like STATCOMs or capacitors can be used to meet voltage control requirements.

Active Power and Frequency Response

Is frequency ride-through required?

Yes, IBRs must stay online during specified over/under-frequency events and provide frequency response.

What is Fast Frequency Response (FFR)?

It’s a rapid injection or reduction of active power in milliseconds to stabilize frequency deviations.

What is Primary Frequency Response (PFR)?

It refers to autonomous, proportional power changes in response to frequency deviations.

Ride-Through Capabilities

Do IBRs need to ride through faults?

Yes, they must ride through voltage and frequency disturbances instead of disconnecting prematurely.

Can GOs include ride-through limits in their protection settings?

Only within the constraints allowed in the standard (e.g., voltage vs. time profiles in the standard’s annexes).

Modeling and Validation

What modeling data must Generator Owners provide?

Dynamic models for steady-state, transient, EMT, and harmonic studies; test data; performance verification.

Are electromagnetic transient (EMT) models required?

Yes, especially for weak grid or high-inverter penetration scenarios.

What platforms are accepted for modeling?

PSSE, PSCAD, DigSILENT PowerFactory, and similar platforms as per utility requirements.

Protection

What protection schemes must be included?

ROCOF, over/under voltage, over/under frequency, islanding detection, and fault ride-through compliant schemes.

Do anti-islanding functions have to trip immediately?

They must operate within specific detection times while coordinating with grid-side protection.

Communication and Control

Is secure communication with the TS operator required?

Yes, IBRs must include interfaces for data exchange, alarms, and control signals.

What control capabilities must be implemented?

Active and reactive power control, ramp rates, power factor settings, voltage/frequency droop, etc.

Lifecycle Compliance

Is ongoing compliance required after commissioning?

Yes, compliance must be maintained throughout the plant’s operational life.

What if TS conditions change (e.g., new nearby plants)?

GOs may be required to re-tune control settings or implement upgrades per mutually agreed remedies.

Legal and Interconnection

Does IEEE 2800 override utility-specific requirements?

No, utilities may impose additional or stricter requirements in a non-discriminatory way.

Is grandfathering allowed for older IBRs?

Possibly, but any major modification may require full compliance with IEEE 2800.

What happens if compliance is not met?

Non-compliance may delay interconnection approval or result in operational curtailment or penalties.