A Coordinated Electric System Interconnection Review—the utility’s deep-dive on technical and cost impacts of your project.

Expert Commissioning of MV & LV Electrical Systems by Keentel Engineering

May 6, 2025 | Blog

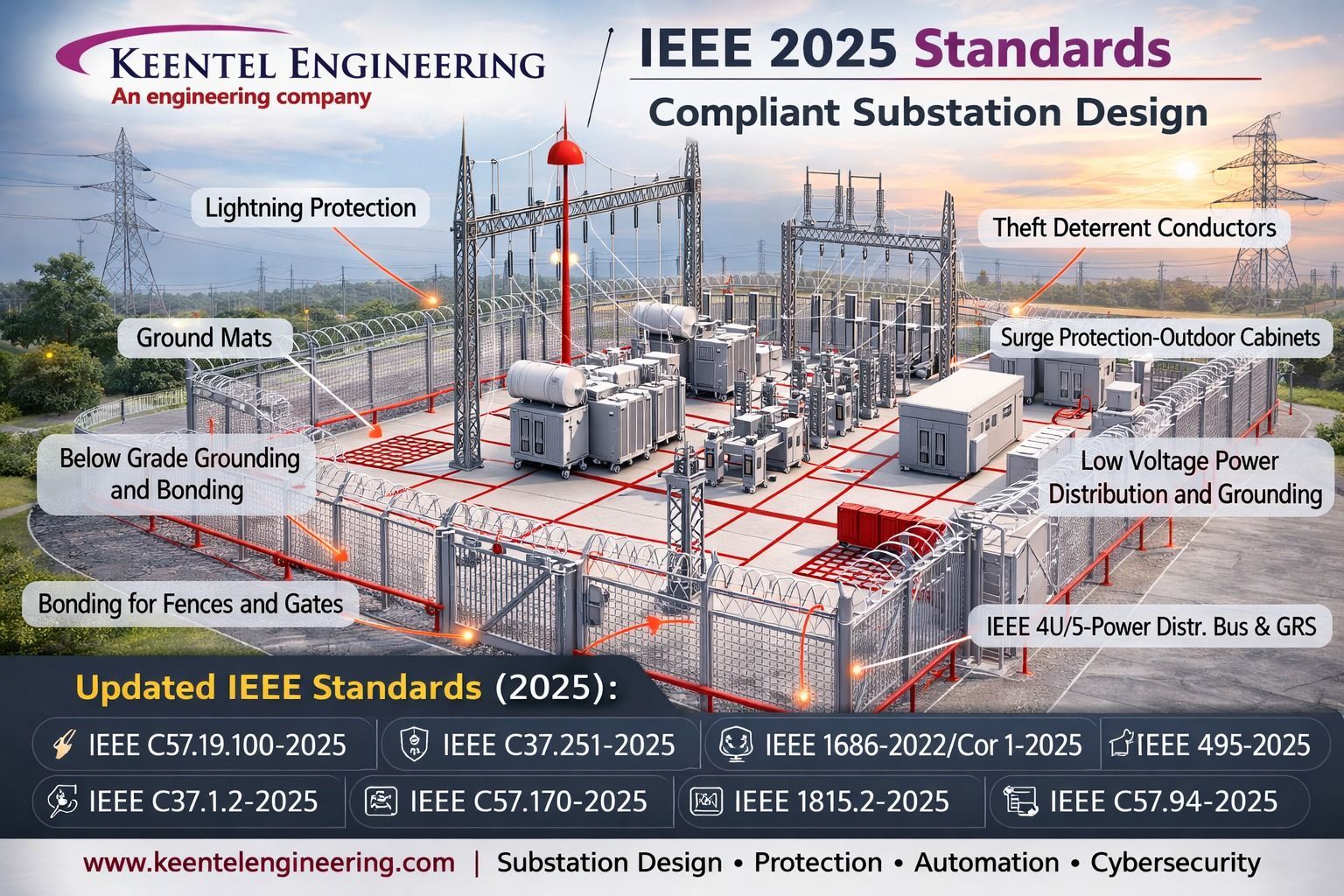

At Keentel Engineering, we understand that the foundation of any safe and efficient power system lies in its commissioning. Our commissioning services for low-voltage (LV) and medium-voltage (MV) systems are built around the rigorous standards of ANSI/NETA ATS-2017, ensuring reliability, compliance, and performance from day one.

From utility-scale substations to warehouse MEP system upgrades, we serve clients across North America, delivering expert commissioning solutions tailored to diverse industrial, commercial, and renewable energy applications.

Understanding Electrical Commissioning

Electrical commissioning is a structured validation process to confirm that all electrical systems are designed, installed, and tested to meet operational and safety criteria. This includes a full suite of inspections, performance verifications, and documentation efforts that span visual and mechanical reviews, calibration of devices, and power system performance validation.

Our engineers don’t just test components—they integrate them into a reliable whole. The process verifies that breakers, switchgear, relays, transformers, and other components perform under real-world conditions. Our team also reviews control logic and communication protocols to ensure fault detection, coordination, and system recovery work seamlessly.

Why Choose Keentel Engineering?

Backed by over three decades of experience in power system engineering, relay testing, and NERC compliance, Keentel brings the technical depth required for even the most complex commissioning projects. Our engineers hold ANSI/NETA ETT certifications and routinely work in high-risk, high-performance environments like industrial plants, solar farms, and mission-critical facilities.

We’re trusted not only for our technical expertise but for our audit-ready documentation, system reliability improvements, and ability to integrate commissioning into broader MEP or POI interconnection projects.

Commissioning Services We Provide

Every commissioning plan we deliver is built around system-specific requirements. Here’s how we support your success:

Functionality Testing

We confirm operational readiness of protection relays, automatic transfer switches (ATS), CT/PT circuits, and sensing devices. Functionality testing ensures your equipment will respond correctly during faults or outages—minimizing system risks and improving uptime.

Power System Studies and Optimization

We provide all major engineering studies as part of commissioning or retrofitting:

- Short-circuit analysis to identify overstress scenarios

- Protective device coordination to prevent nuisance trips

- Arc flash hazard assessment to meet NFPA 70E and IEEE 1584

- Load flow and harmonic analysis to improve energy efficiency and reliability

These studies are particularly essential when upgrading MEP systems in warehouses, manufacturing plants, and energy-intensive facilities.

Physical and Electrical Inspections

Following Sections 7.1–7.25 of ANSI/NETA ATS, we test:

- Switchgear and relay panels

- Diesel and backup generators

- Transformers and UPS systems

- Fiber-optic and SCADA infrastructure

This ensures proper phasing, insulation, breaker timing, and ground integrity—critical for both safety and compliance.

Thermographic Surveys

Using high-resolution infrared cameras, we inspect terminations and bus bars for thermal anomalies. We also establish thermographic baselines for ongoing condition monitoring, a crucial step for facilities aiming to reduce maintenance risks.

EMF and Environmental Testing

Our team performs electromagnetic field (EMF) assessments to ensure compliance with national safety thresholds—an increasingly relevant metric in high-density industrial or warehouse environments.

FAQs | MV & LV Electrical Systems

What is ANSI/NETA ATS-2017?

American standard for acceptance testing specifications of electrical equipment and systems.

Is commissioning different from routine maintenance?

Yes—commissioning occurs pre-energization or after major retrofits; maintenance is periodic.

Do I need to perform arc-flash studies during commissioning?

Yes—critical for determining PPE levels and proper equipment labeling.

Are thermographic surveys required?

Optional but highly recommended under load to identify abnormal heating.

Which test equipment is required?

All instruments must be calibrated per NIST traceable standards within the past 12 months.

Who is authorized to conduct these tests?

Only technicians certified by NETA-accredited or equivalent organizations.

What is the purpose of a coordination study?

Ensure selective fault isolation without unnecessary system shutdowns.

How is a short-circuit study conducted?

Analyze fault currents and component withstand capabilities per IEEE 399 & 242.

What is the load-flow study for?

Optimizing voltage, current levels, and power factor across scenarios.

What documentation is required after testing?

Complete reports with test data, environmental conditions, technician IDs, and stamped summaries.

Can commissioning be done after energization?

Only with strict safety protocols; pre-energization is preferred.

What is a test decal?

A color-coded label (white/yellow/red) indicating equipment condition status post-testing.

Is insulation-resistance testing mandatory?

Yes; results must meet IEEE Std. 43 thresholds for motors and transformers.

Are harmonic studies mandatory?

Optional, crucial when nonlinear loads (e.g., VFDs) are present.

What is system function testing?

Verifies correct operation of sensing, logic, and action components across devices.

How often should follow-up commissioning occur?

Thermographic surveys within 12 months; other tests based on system criticality.

What are acceptable bushings power factor values?

Within ±10% of nameplate ratings.

Can Keentel assist with NEC/NFPA 70E compliance?

Yes—we ensure commissioning aligns with OSHA, NEC, and NFPA regulations.

How do you verify relay settings?

Through field testing against design and coordination study outputs.

Do you provide stamped reports for permitting?

Yes—our P.E. seals reports as required for regulatory and permitting submissions.

Case Studies

Pharmaceutical Facility – Arc Flash & Coordination Commissioning

Keentel delivered a full commissioning scope on a 480V system with MCCs and generators. We conducted arc flash, short-circuit, and coordination studies, verified relay settings, and applied NFPA 70E-compliant labeling. As a result, relay coordination improved, PPE zones were defined, and OSHA/IEEE compliance was fully achieved.

Scope

A 480V system with five MCCs, multiple panels, and standby generators.

Keentel’s Role

- Performed short-circuit, arc flash, and coordination studies

- Generated compliant labels per NFPA 70E

- Verified relay settings and tested protective devices

Outcome

- PPE categories established

- Improved coordination minimized nuisance tripping

- Full compliance with OSHA 1910.269 and IEEE 1584

Solar Farm – MV Substation Commissioning

For a 34.5kV substation interconnection, our team performed system energization, relay wiring verification, and SCADA interface testing. All work followed ANSI/NETA ATS Section 8, with zero protection failures upon startup. We also established thermal inspection benchmarks to support predictive maintenance.

Scope

34.5 kV switchgear, step-up transformers, breakers, and fiber optic SCADA links

Keentel’s Role

- Completed functional system testing under Section 8 of ANSI/NETA ATS

- Verified CT/PT ratios and protective relay wiring

- Performed system energization support

Outcome

- Zero protection failures during energization

- Interconnection approved without delays

- Thermographic baseline survey established for maintenance tracking

Data Center – UPS & Generator Testing

Our commissioning covered redundant UPS systems, ATS panels, and fiber rings. We performed insulation resistance, load bank testing, harmonic monitoring (IEEE 519), and failover simulations. The client achieved full uptime certification, and our final test reports enabled internal audit signoff.

Scope

Redundant UPS, battery banks, diesel gensets, ATS panels, fiber ring

Keentel’s Role

- Electrical and mechanical inspection of UPS and emergency systems per Sections 7.22.2 and 7.22.1

- Load testing, insulation resistance, and harmonic distortion measurement

- Verified failover operations via system function tests

Outcome

- Continuous uptime verified under full load

- Reduced harmonic distortion within IEEE 519 limits

- Delivered a full test report with recommendations and asset labeling

NERC CIP Compliance and Risk Management

Keentel Engineering supports energy providers and large-scale users in managing critical infrastructure protection (CIP) responsibilities. Our commissioning process feeds directly into your compliance roadmap with deliverables like:

- NERC RSAW documentation

- Generator and relay model validation

- Audit support for compliance and interconnection

Commission with Confidence

Whether you’re building a new warehouse, upgrading an industrial MEP system, or commissioning a POI interconnection for a solar farm, Keentel Engineering offers commissioning solutions that scale. Our services span LV, MV, and HV systems and are backed by licensed engineers, deep compliance knowledge, and utility-tested workflows.

Partner with Keentel Engineering & Get Electrical Commissioning Services

Ensure your electrical system is safe, compliant, and optimized for long-term performance. Contact Keentel Engineering for a commissioning proposal tailored to your facility’s needs.

About the Author:

Sonny Patel P.E. EC

IEEE Senior Member

In 1995, Sandip (Sonny) R. Patel earned his Electrical Engineering degree from the University of Illinois, specializing in Electrical Engineering . But degrees don’t build legacies—action does. For three decades, he’s been shaping the future of engineering, not just as a licensed Professional Engineer across multiple states (Florida, California, New York, West Virginia, and Minnesota), but as a doer. A builder. A leader. Not just an engineer. A Licensed Electrical Contractor in Florida with an Unlimited EC license. Not just an executive. The founder and CEO of KEENTEL LLC—where expertise meets execution. Three decades. Multiple states. Endless impact.

Services

Let's Discuss Your Project

Let's book a call to discuss your electrical engineering project that we can help you with.

About the Author:

Sonny Patel P.E. EC

IEEE Senior Member

In 1995, Sandip (Sonny) R. Patel earned his Electrical Engineering degree from the University of Illinois, specializing in Electrical Engineering . But degrees don’t build legacies—action does. For three decades, he’s been shaping the future of engineering, not just as a licensed Professional Engineer across multiple states (Florida, California, New York, West Virginia, and Minnesota), but as a doer. A builder. A leader. Not just an engineer. A Licensed Electrical Contractor in Florida with an Unlimited EC license. Not just an executive. The founder and CEO of KEENTEL LLC—where expertise meets execution. Three decades. Multiple states. Endless impact.

Leave a Comment

We will get back to you as soon as possible.

Please try again later.

Related Posts