A Coordinated Electric System Interconnection Review—the utility’s deep-dive on technical and cost impacts of your project.

What is Arc Flash? Causes, Hazards & OSHA-Compliant Prevention

January 17, 2022 | Blog

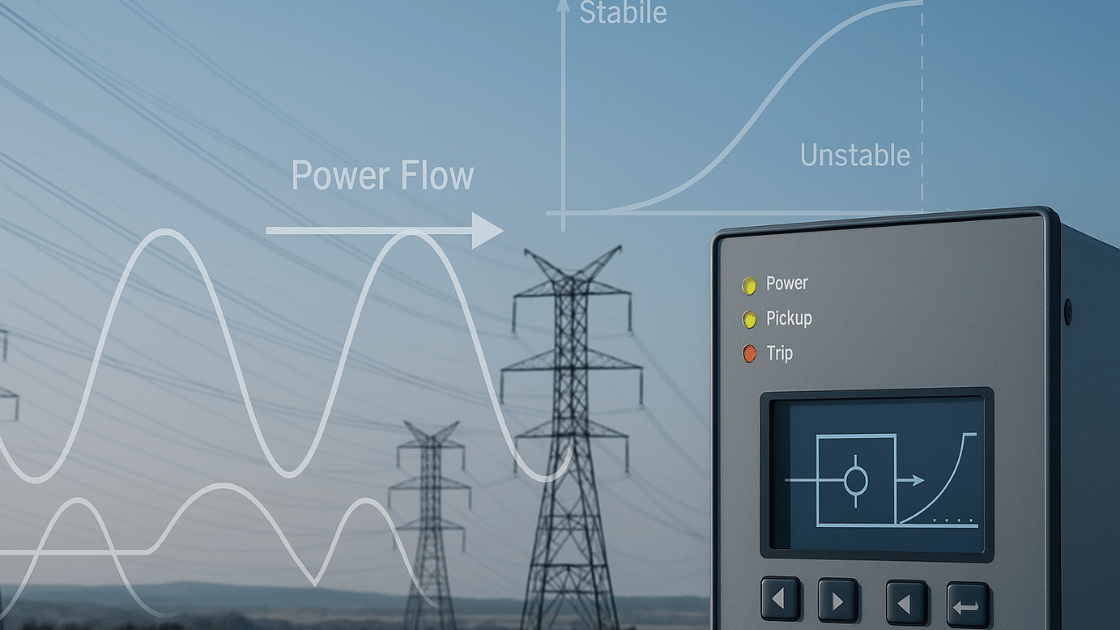

If you work in the utility or power systems industry, understanding arc flash hazards is crucial. Also known as a flashover, an arc flash is a sudden, violent electrical explosion or discharge. It occurs when electric current jumps through the air from one conductor to another—or to the ground—causing a high-temperature arc fault.

This rapid energy release often happens between phase-bus bars or conductors with voltages above 120V. The result? A blast of hot plasma, flying molten metal, and lethal shrapnel. Arc flashes are not just dangerous—they're deadly, and compliance with OSHA safety standards is critical.

Causes of Arc Flash

An arc flash incident is typically triggered by:

- Unintentional contact with energized equipment or conductors

- Equipment failure, especially in aging or improperly maintained systems

The risk level of an arc flash depends on:

- The fault current capacity

- The duration of the fault

- The chemical composition of conductors (e.g., copper, aluminum)

Top Common Causes

- Dropping metal tools near energized equipment

- Incorrect use of test instruments

- Live work on faulty or damaged components

- Loose wiring, exposed conductors, or degraded insulation

- Lack of arc flash training and human error

OSHA-Compliant Arc Flash Prevention Strategies

Prevention is key to reducing arc flash risk and ensuring compliance with OSHA 1910.269 and NFPA 70E standards. Here are recommended control measures:

1. Hire a Qualified Engineering Firm

Engaging experts in substation design and power system studies ensures your facility meets all OSHA and NESC compliance requirements.

Explore Our Substation Design Services

Need a Study? View Our Power System Studies Services

2. Implement a Safety Program

A formal arc flash risk assessment includes:

- Fault current analysis

- Arc flash boundary calculations

- Incident energy assessments

- Safety labeling and signage

This documentation is essential during NERC compliance audits and plant safety inspections.

3. Additional Arc Flash Control Measures

- De-energize equipment before maintenance or testing

- Provide and enforce the use of PPE (Personal Protective Equipment)

- Maintain safe working distances from live components

- Reduce the system fault energy through engineering design

- Conduct regular worker training, mock drills, and toolbox talks

- Perform ongoing system audits and maintenance

Why Choose Keentel Engineering for Arc Flash Compliance?

At Keentel Engineering, we don’t just identify arc flash hazards—we engineer safe, compliant, and cost-effective solutions. Our licensed engineers provide:

- Comprehensive Arc Flash Studies

- System modeling using ETAP, SKM, and other tools

- Training and guidance aligned with OSHA, NFPA, and IEEE standards

Contact Us today to speak with a licensed professional about compliance support.

FAQs About Arc Flash

Q1: What’s the difference between arc flash and arc blast?

Arc flash is the electrical discharge; arc blast is the pressure wave and shrapnel caused by the explosion.

Q2: Is arc flash compliance part of NERC audits?

While not a NERC standard by itself, arc flash analysis is often part of broader reliability and safety assessments, particularly during substation or transmission upgrades.

Q3: How often should arc flash studies be updated?

Typically every 5 years or whenever major electrical system changes occur.

Final Thoughts

An arc flash event can cripple operations, injure personnel, or even result in fatalities. That’s why prevention, system modeling, and OSHA compliance are non-negotiable. Partner with Keentel Engineering to assess, mitigate, and engineer out risk.

About the Author:

Sonny Patel P.E. EC

IEEE Senior Member

In 1995, Sandip (Sonny) R. Patel earned his Electrical Engineering degree from the University of Illinois, specializing in Electrical Engineering . But degrees don’t build legacies—action does. For three decades, he’s been shaping the future of engineering, not just as a licensed Professional Engineer across multiple states (Florida, California, New York, West Virginia, and Minnesota), but as a doer. A builder. A leader. Not just an engineer. A Licensed Electrical Contractor in Florida with an Unlimited EC license. Not just an executive. The founder and CEO of KEENTEL LLC—where expertise meets execution. Three decades. Multiple states. Endless impact.

Services

Let's Discuss Your Project

Let's book a call to discuss your electrical engineering project that we can help you with.

About the Author:

Sonny Patel P.E. EC

IEEE Senior Member

In 1995, Sandip (Sonny) R. Patel earned his Electrical Engineering degree from the University of Illinois, specializing in Electrical Engineering . But degrees don’t build legacies—action does. For three decades, he’s been shaping the future of engineering, not just as a licensed Professional Engineer across multiple states (Florida, California, New York, West Virginia, and Minnesota), but as a doer. A builder. A leader. Not just an engineer. A Licensed Electrical Contractor in Florida with an Unlimited EC license. Not just an executive. The founder and CEO of KEENTEL LLC—where expertise meets execution. Three decades. Multiple states. Endless impact.

Leave a Comment

We will get back to you as soon as possible.

Please try again later.