A Coordinated Electric System Interconnection Review—the utility’s deep-dive on technical and cost impacts of your project.

Challenge: Frequent false tripping using conventional electromechanical relays

Solution: SEL-487E integration with multi-terminal differential protection and dynamic inrush restraint

Result: 90% reduction in false trips, saving over $250,000 in downtime

Ensuring Design Stability in Power System Projects: Best Practices and Upcoming NERC Reporting Deadlines

May 30, 2025 | Blog

Introduction

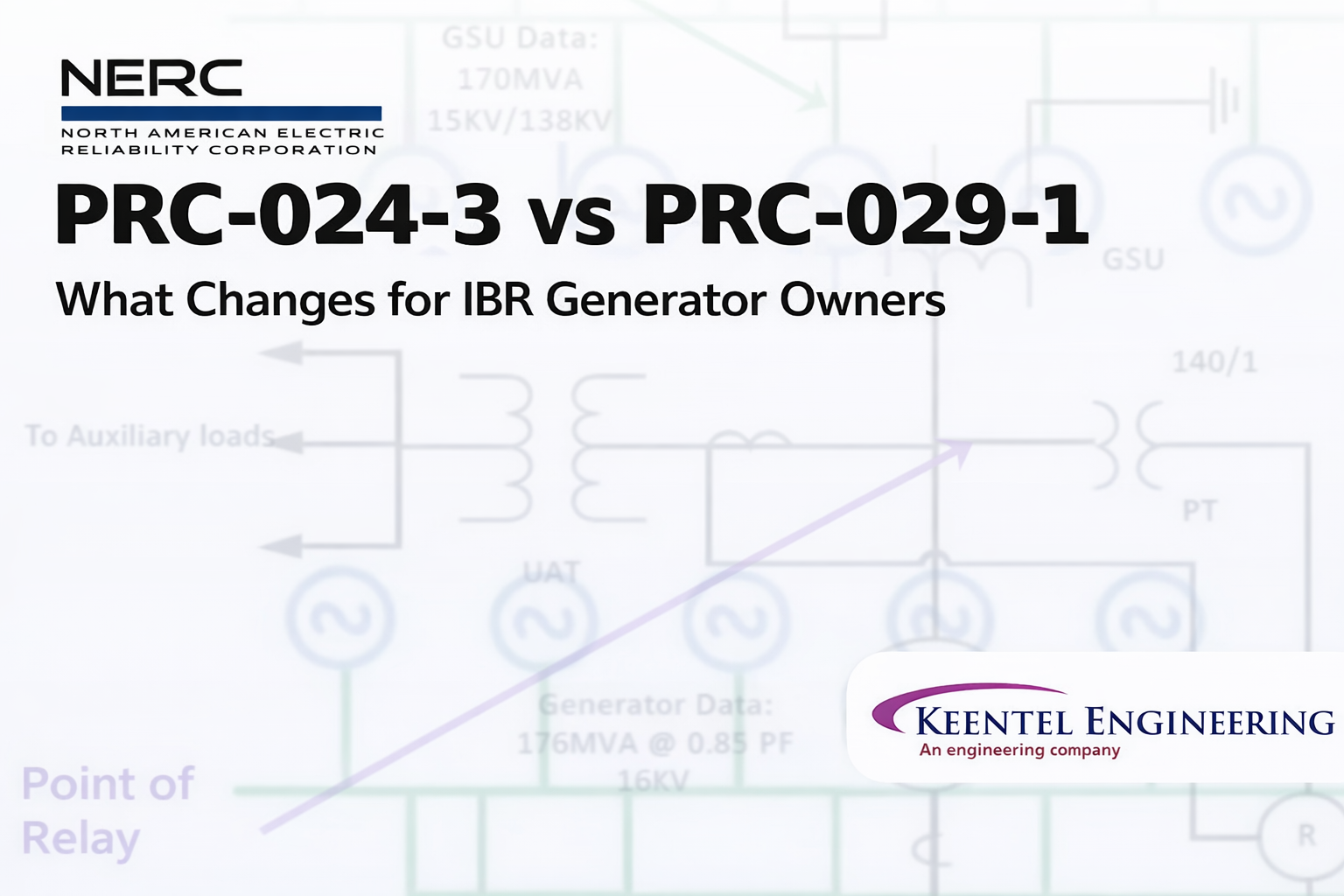

In today’s rapidly evolving electric grid landscape, design stability is critical for maintaining reliable, resilient, and compliant infrastructure. Stability issues, if not addressed early, can derail project timelines, increase costs, and create compliance risks. With growing scrutiny from NERC (North American Electric Reliability Corporation) and other regulatory bodies, it is essential for project developers and engineers to adopt best practices that minimize late-stage design or model changes.

This blog explores how leveraging publicly available interconnection requirements, early OEM (Original Equipment Manufacturer) engagement, and clear purchase agreement clauses can strengthen design stability. Additionally, it outlines key reporting deadlines for NERC compliance in 2025, including:

- Acknowledge Alert: By May 27, 2025

- Submit Report to NERC: By August 18, 2025

Why Design Stability Matters in Grid Interconnection

Power system design is inherently complex. In large-scale grid-tied projects—particularly those involving inverter-based resources (IBRs) such as solar, wind, or battery storage—stability must be ensured from initial modeling to operational handover.

Design stability means:

- Minimizing unexpected changes to the power flow, dynamic models, and protection schemes.

- Aligning with transmission operator and interconnection authority requirements.

- Ensuring that changes in equipment, topology, or control systems do not introduce new reliability risks.

Benefits of Stable Design:

- Fewer rework cycles during validation or commissioning.

- On-time regulatory approvals from ISOs/RTOs and utilities.

- Reduced project risk and stronger financial forecasting.

Key Strategy 1: Use Publicly Posted Interconnection Requirements

What Are Interconnection Requirements?

ISOs, RTOs, and utilities publish interconnection standards and procedures that define what’s expected for modeling, controls, data exchange, and physical connection.

These include:

- Fault ride-through capabilities

- Reactive power requirements

- Modeling formats (e.g., PSSE, PSCAD)

- Frequency/watt and voltage/reactive curves

Why Reference These Early?

Referencing posted interconnection requirements at the design stage enables teams to:

- Avoid non-compliant model iterations.

- Reduce last-minute NERC audit issues.

- Align component specs and controls with ISO needs (e.g., ERCOT’s DWG Procedures or CAISO’s MDWG Requirements).

Key Strategy 2: Engage OEMs Early in the Modeling Lifecycle

Why OEM Engagement Matters

Original Equipment Manufacturers (OEMs) provide models for inverters, turbines, transformers, protection systems, and control schemes. These models are essential for interconnection studies, particularly dynamic simulations.

Engaging OEMs early helps:

- Customize model behavior to meet specific grid codes.

- Validate models before final equipment selection.

- Ensure model-file deliverables (PSSE, PSCAD, TSAT) are available for timely submission.

How to Engage OEMs Effectively

- Initiate technical discussions during procurement planning.

- Include modeling timelines and deliverables in RFPs and purchase agreements.

- Request generic + detailed user-defined models with documented block diagrams.

- Clarify NDA and data use policies for regulatory submission.

Key Strategy 3: Include Modeling Deliverables in Purchase Agreements

What to Include in Contracts

Contracts with OEMs should specify:

- Timeline for model delivery (e.g., within 30 days of contract execution).

- Model formats (e.g., *.dyr, *.dll, *.psim).

- Model test reports (frequency response, voltage regulation, etc.).

- Technical support during ISO/RTO validation.

Legal and Financial Leverage

When modeling deliverables are written into contracts:

- Delays can be penalized.

- Scope creep can be managed via formal change orders.

- Model quality can be contractually linked to milestone payments.

Upcoming NERC Reporting Deadlines for 2025

To ensure grid reliability and modeling accuracy, NERC has issued new alerts requiring specific actions:

Deadline 1: Acknowledge Alert – May 27, 2025

Registered entities must acknowledge receipt of the alert, confirming awareness of their obligations regarding model validation and design practices.

Deadline 2: Submit Report to NERC – August 18, 2025

Reports must detail:

- OEM model usage

- Modeling scope and assumptions

- Changes made to improve design stability

- Any deviations from posted interconnection requirements

Failure to comply can lead to:

- Fines

- Project certification delays

- Public non-compliance listings

Summary: Action Plan for Developers and Engineers

| Action Item | Description | Timeline |

|---|---|---|

| Review ISO/RTO interconnection guidelines | Integrate into design workflows | Review ISO/RTO interconnection guidelines Integrate into design workflows Immediately |

| Engage OEMs for early model delivery | Align on formats and deliverables | Q2 2025 |

| Update contracts | Add modeling-related milestones | Before procurement |

| Acknowledge NERC Alert | Submit acknowledgment | By May 27, 2025 |

| Submit full report to NERC | Include all model updates | By August 18, 2025 |

Final Thoughts

Design stability is no longer optional—it’s a compliance mandate and a competitive advantage. By embedding regulatory, technical, and procurement practices into your workflows, your project can avoid late-stage redesigns, pass audits smoothly, and bring long-term operational certainty.

For engineering consultants like Keentel Engineering, implementing these practices ensures your clients achieve both grid code compliance and design resilience across the project lifecycle.

Frequently Asked Questions (FAQs)

1. What is design stability in power system projects?

Design stability refers to maintaining consistent technical design and modeling throughout the development lifecycle to avoid late-stage changes.

2. Why are interconnection requirements important?

They set technical and regulatory expectations. Adhering to them early reduces the risk of non-compliance and rework.

3. How can publicly posted interconnection requirements be accessed?

They are typically published on ISO/RTO websites under generator interconnection or planning sections.

4. What is the role of OEMs in design stability?

OEMs provide critical dynamic and static models for simulation and compliance with grid codes.

5. What model formats are usually required by ISOs?

Common formats include PSSE (.dyr), PSCAD (.psim), and user-defined models (*.dll, *.blk).

6. What is the significance of the May 27, 2025, deadline?

This is the deadline to acknowledge receipt of the NERC alert about model quality and design stability.

7. What needs to be included in the August 18, 2025, report?

Details about modeling practices, OEM engagement, and compliance with interconnection requirements.

8. What happens if modeling deliverables are delayed?

It can delay ISO approvals, regulatory filings, and project energization.

9. Can model changes trigger NERC violations?

Yes. Unapproved or undocumented model changes can lead to compliance violations and penalties.

10. How early should OEMs be engaged?

Ideally, before final equipment selection or during the RFP stage.

11. What should be in a purchase agreement regarding modeling?

Deadlines, model formats, technical support, test reports, and penalties for delay.

12. How can developers track interconnection changes?

Set up alerts for ISO/RTO guideline updates or subscribe to planning newsletters.

13. Are these NERC requirements applicable to all regions?

Yes, for all NERC-registered entities across North America.

14. Who prepares the report to NERC?

Typically the project developer or the registered Generator Owner, often with engineering consultant support.

15. How can Keentel Engineering assist with design stability?

By providing ISO-compliant models, coordinating with OEMs, drafting contracts, and preparing regulatory reports.

About the Author:

Sonny Patel P.E. EC

IEEE Senior Member

In 1995, Sandip (Sonny) R. Patel earned his Electrical Engineering degree from the University of Illinois, specializing in Electrical Engineering . But degrees don’t build legacies—action does. For three decades, he’s been shaping the future of engineering, not just as a licensed Professional Engineer across multiple states (Florida, California, New York, West Virginia, and Minnesota), but as a doer. A builder. A leader. Not just an engineer. A Licensed Electrical Contractor in Florida with an Unlimited EC license. Not just an executive. The founder and CEO of KEENTEL LLC—where expertise meets execution. Three decades. Multiple states. Endless impact.

Services

Let's Discuss Your Project

Let's book a call to discuss your electrical engineering project that we can help you with.

About the Author:

Sonny Patel P.E. EC

IEEE Senior Member

In 1995, Sandip (Sonny) R. Patel earned his Electrical Engineering degree from the University of Illinois, specializing in Electrical Engineering . But degrees don’t build legacies—action does. For three decades, he’s been shaping the future of engineering, not just as a licensed Professional Engineer across multiple states (Florida, California, New York, West Virginia, and Minnesota), but as a doer. A builder. A leader. Not just an engineer. A Licensed Electrical Contractor in Florida with an Unlimited EC license. Not just an executive. The founder and CEO of KEENTEL LLC—where expertise meets execution. Three decades. Multiple states. Endless impact.

Leave a Comment

We will get back to you as soon as possible.

Please try again later.

Related Posts