A Coordinated Electric System Interconnection Review—the utility’s deep-dive on technical and cost impacts of your project.

White Paper: Gas Insulated Substations (GIS) – Enhancing Power Network Reliability and Efficiency

May 14, 2025 | Blog

Introduction

As demand grows for compact, reliable, and low-maintenance electrical infrastructure, Gas Insulated Substations (GIS) are playing a crucial role in modern high-voltage power systems. This white paper outlines the advantages, design configurations, equipment, and commissioning protocols of GIS, a core technology in today’s power substation engineering landscape. In modern GIS power systems, these installations enable utilities to deploy high-performance infrastructure where conventional layouts are not feasible, particularly in dense urban, industrial, and environmentally challenging environments.

Successful projects begin with experienced electrical engineers. Our team provides

electrical substation design services for utilities, renewable developers, and EPC contractors requiring reliable, compliant infrastructure.

What is a Gas Insulated Substation (GIS)?

A Gas Insulated Substation (GIS) houses high-voltage equipment such as circuit breakers, disconnectors, and busbars inside metal-enclosed modules filled with SF₆ gas. Due to its high dielectric strength and arc-quenching capability, GIS is well suited for HV and EHV applications, especially in space-constrained or environmentally hostile locations.

In electrical engineering, GIS refers to enclosing energized components within grounded metal compartments, creating a sealed and controlled operating environment. In a GIS power substation, this configuration improves insulation integrity, minimizes contamination risk, and enables deployment inside buildings or underground facilities. Typical systems may include a GIS transformer interface, modular enclosures, protection-ready panels, and scalable unitized assemblies.

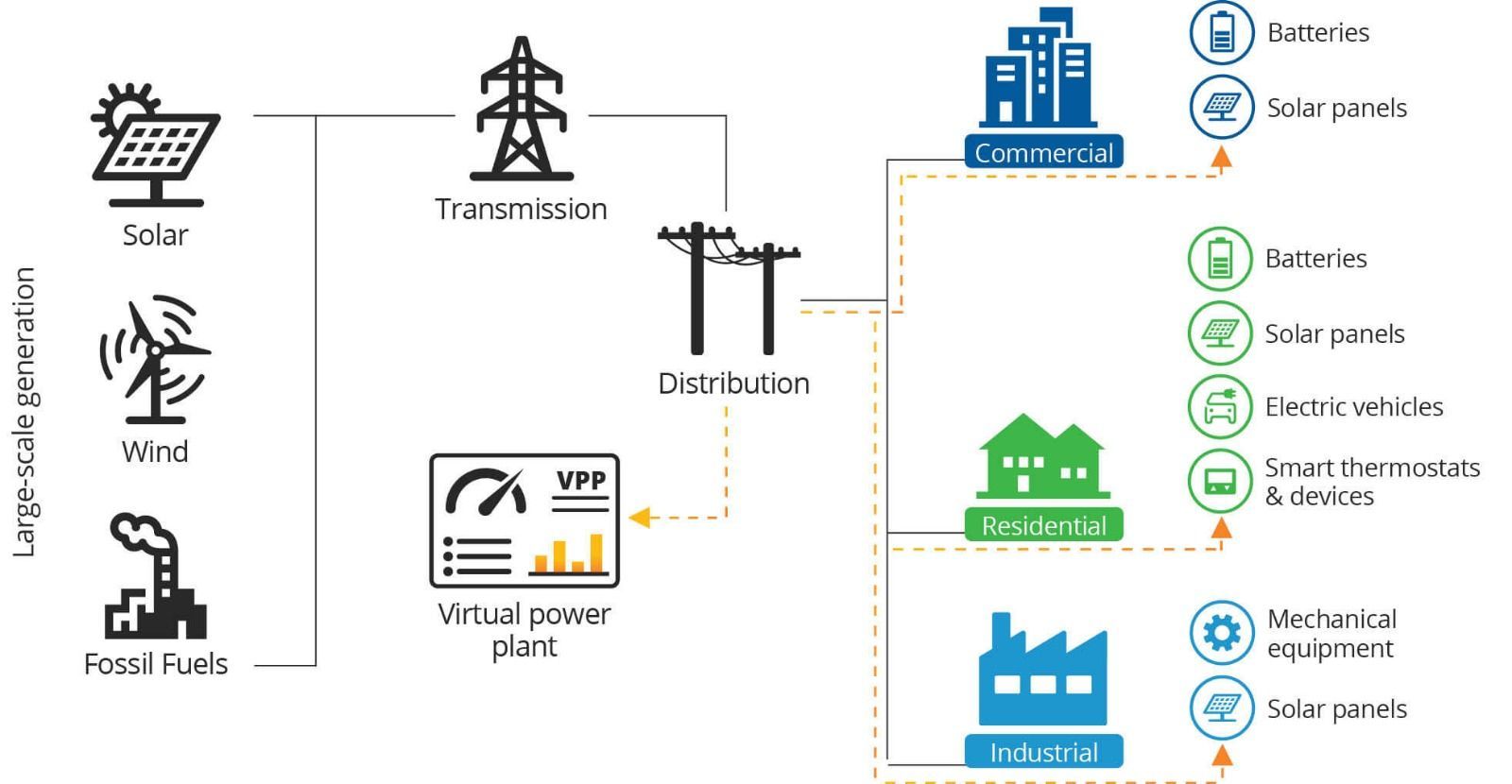

Types of Substations and Their Functions

Substations serve as essential nodes in power transmission and distribution systems, responsible for transformation, switching, protection, and monitoring. Key classifications include:

- By function: Step-up, step-down

- By voltage level: HV, EHV, UHV

- By design: Outdoor, Indoor, Hybrid

- By insulation: AIS (Air-Insulated), GIS (Gas-Insulated)

Utilities increasingly deploy GIS grid stations and GIS grid substations in locations where land availability, reliability requirements, or environmental conditions limit conventional construction. These GIS stations function as critical transmission or distribution nodes within dense networks.

GIS vs AIS: Comparative Advantage

| Feature | GIS | AIS |

|---|---|---|

| Space | Up to 70% smaller | Requires large area |

| Maintenance | Low | High |

| Safety | High | Medium |

| Initial Cost | Higher | Lower |

| Fault Damage | More severe | Better containment |

GIS is preferred where space efficiency, reliability, and maintenance reduction are critical. In some projects, utilities adopt hybrid GIS substation configurations that combine gas-insulated bays with air-insulated sections, balancing cost, footprint, and operational flexibility through hybrid insulated switchgear.

GIS Busbar Configurations

Common GIS bus schemes include:

- Single Bus Single Breaker

- Double Bus Single Breaker

- Double Bus Double Breaker

- Ring Bus

- Breaker-and-a-Half

Internally, GIS systems rely on gas insulated bus arrangements and sealed bus ducts to interconnect bays with minimal electrical loss. In larger installations, a gas insulated switchyard configuration replaces conventional outdoor layouts while maintaining high reliability.

Key Switchgear Components in GIS

GIS installations typically include:

- Circuit breakers for interrupting high-current faults

- Disconnectors and earth switches for isolation and grounding

- Instrument transformers for accurate measurement

- Control and protection panels supporting SCADA, relays, and monitoring

Additional components such as GIS bushings, modular GIS units, and integrated panels form the backbone of modern GIS electrical installations.

SF₆ Gas in GIS – Benefits & Environmental Cautions

SF₆ gas is chemically inert, non-toxic, and provides superior insulation performance. However, due to its high global warming potential, strict handling procedures are required. Proper gas management ensures safe gas insulated switchgear operation and long-term regulatory compliance.

Mitigation strategies include continuous leak detection, gas density monitoring, alarms, and proper recovery and recycling protocols.

GIS Installation & Commissioning Process

The installation and commissioning process typically includes:

- Foundation setup

- Gas tightness testing

- Contact resistance measurement

- SF₆ gas filling and leak verification

- Functional testing of breakers, relays, and switches

- Moisture and dew-point testing

- Insulation and auxiliary system tests

- Final integration, commissioning, and quality assurance

Post-commissioning programs address gas insulated switchgear maintenance requirements to ensure pressure stability, contact integrity, and long-term operational reliability.

Applications of GIS in Power Networks

GIS solutions are best suited for:

- Urban substations with limited space

- High-pollution or coastal environments

- Underground or enclosed installations

- Industrial zones

- Emergency or mobile substations

Additional applications include GIS power stations near load centers, outdoor GIS substations in harsh climates, and compact transmission corridors using gas insulated transmission lines.

GIS System Architecture and Hybrid Configurations

Modern GIS installations often integrate sealed switchyard layouts with mixed insulation technologies. Hybrid GIS configurations allow utilities to combine gas-insulated bays with conventional equipment, optimizing cost while preserving footprint advantages. These systems are commonly deployed where expansion or retrofit constraints exist.

Conclusion

Gas Insulated Substations significantly enhance grid reliability, reduce maintenance demands, and support compact design requirements. When engineered, tested, and monitored correctly, GIS delivers long-term performance for utilities, developers, and EPC firms operating across urban and high-risk environments. Understanding the different types of gas insulated substation configurations allows stakeholders to select solutions aligned with space, voltage, and reliability requirements.

Frequently Asked Questions (FAQs)

What is GIS in substation design?

A substation design using SF₆ gas in compact, insulated modules to house high-voltage components safely.

Why use SF₆ gas?

Due to its superior arc-quenching, dielectric strength, and long-term stability in compact systems.

Main GIS advantages over AIS?

Less space, minimal maintenance, higher safety, and pollution resistance.

GIS voltage range?

Typically 30 kV to 500 kV.

SF₆ concerns?

High GWP — requires proper gas handling, monitoring, and recovery.

Common busbar configurations?

SBSB, DBSB, DBDB, Ring Bus, Breaker-and-a-Half.

How is GIS maintained?

Routine density checks, leak tests, and insulation verification.

Difference: Dead tank vs. Live tank CB?

Dead tank: interrupter grounded. Live tank: interrupter at line voltage.

GIS usage examples?

Urban setups, coastal zones, mobile units, underground networks.

How is contact resistance tested?

With a micro-ohmmeter applying DC current.

Key commissioning tests?

Tightness, contact resistance, dew point, gas leak, relay testing, etc.

Disconnector safety tip?

Always open CB first — prevents dangerous fault arcs.

Can GIS connect directly to transformers?

Yes — with SF₆-to-oil bushings for interface.

Gas pressure monitoring?

Density sensors with alarms and thresholds.

GIS standards?

IEC 62271 series, utility-specific specs, and ANSI ratings.

Case Studies: Real-World GIS Deployments

Case 1 – Urban Substation in Chicago

- Problem: Downtown space constraints

- Solution: 170 kV GIS with Ring Bus

- Result: 70% area reduction, high load reliability

Case 2 – Industrial Facility GIS (Confidential)

- Challenge: Dust, corrosion, harsh climate

- Solution: Sealed GIS with redundant SF₆ sensors

- Result: 99.98% uptime over 5 years

Case 3 – Mobile GIS for Disaster Recovery (California)

- Need: Emergency deployment post-wildfire

- Solution: 34 kV skid-based mobile GIS

- Result: Re-energized 40,000 homes in 72 hours

Case 4 – Retrofit in Aging Substation (Confidential)

- Problem: No extra land for expansion

- Solution: DBDB GIS integrated into existing layout

- Result: 50% space savings and modernized reliability

Case 5 – Coastal Substation

- Challenge: Salt corrosion risk

- Solution: SF₆ gas monitoring + corrosion-proof enclosures

- Result: 10 years of operation without major service

Ready to explore GIS for your project?

Our engineering team has deployed GIS solutions for urban, industrial, and emergency use cases across the U.S.

About the Author:

Sonny Patel P.E. EC

IEEE Senior Member

In 1995, Sandip (Sonny) R. Patel earned his Electrical Engineering degree from the University of Illinois, specializing in Electrical Engineering . But degrees don’t build legacies—action does. For three decades, he’s been shaping the future of engineering, not just as a licensed Professional Engineer across multiple states (Florida, California, New York, West Virginia, and Minnesota), but as a doer. A builder. A leader. Not just an engineer. A Licensed Electrical Contractor in Florida with an Unlimited EC license. Not just an executive. The founder and CEO of KEENTEL LLC—where expertise meets execution. Three decades. Multiple states. Endless impact.

Services

Let's Discuss Your Project

Let's book a call to discuss your electrical engineering project that we can help you with.

About the Author:

Sonny Patel P.E. EC

IEEE Senior Member

In 1995, Sandip (Sonny) R. Patel earned his Electrical Engineering degree from the University of Illinois, specializing in Electrical Engineering . But degrees don’t build legacies—action does. For three decades, he’s been shaping the future of engineering, not just as a licensed Professional Engineer across multiple states (Florida, California, New York, West Virginia, and Minnesota), but as a doer. A builder. A leader. Not just an engineer. A Licensed Electrical Contractor in Florida with an Unlimited EC license. Not just an executive. The founder and CEO of KEENTEL LLC—where expertise meets execution. Three decades. Multiple states. Endless impact.

Leave a Comment

We will get back to you as soon as possible.

Please try again later.