We’re Ready to Take Charge of Your EHV, HV & MV

Electrical Power Engineering

Needs

At Keentel Engineering, Our mission is to deliver sustainable, innovative, and high-quality electrical power engineering solutions tailored to your unique project requirements.

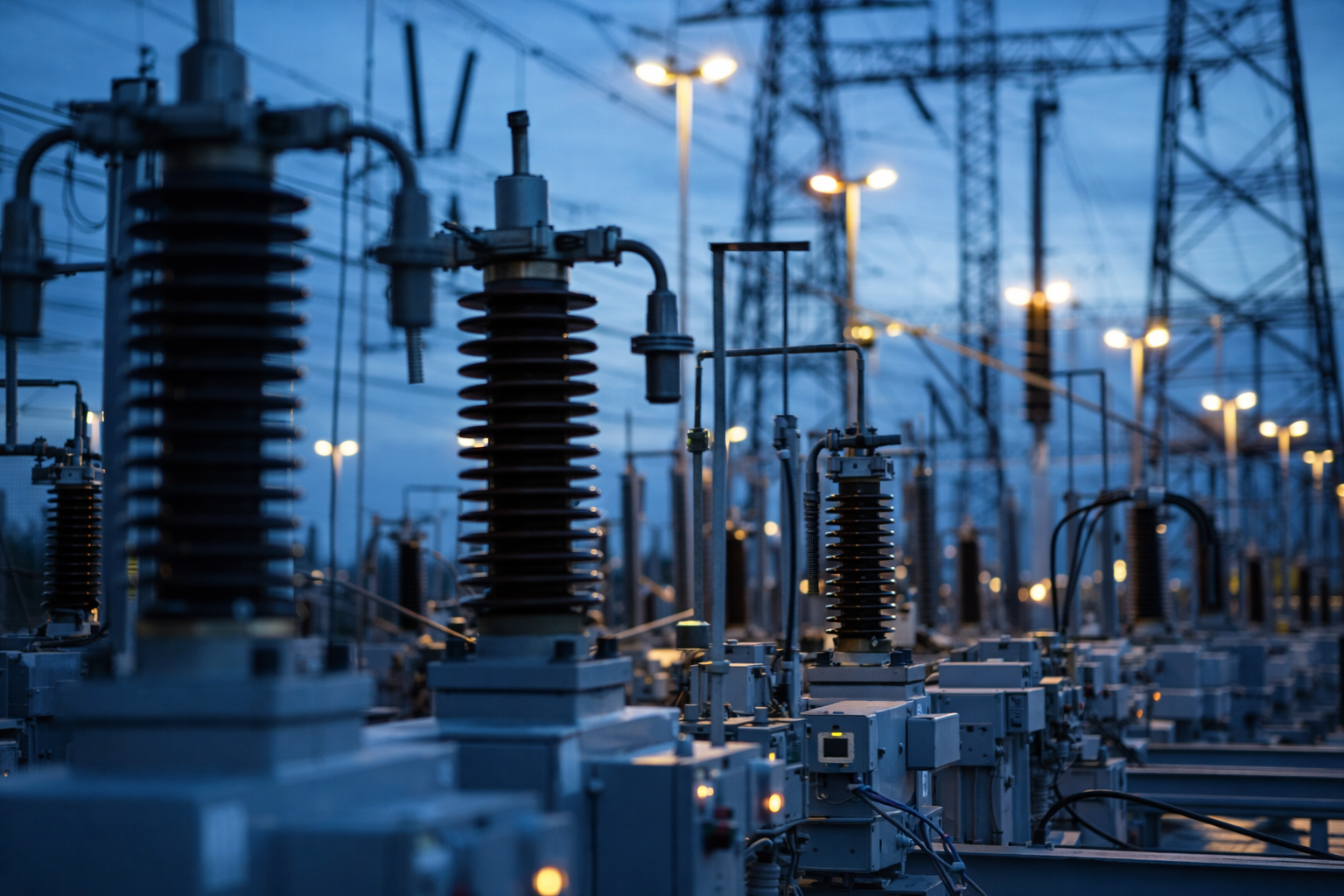

From substation design and POI interconnection engineering support to utility-scale solar, wind, and BESS engineering, we’re your trusted partner in delivering NERC-compliant, future-ready infrastructure across the U.S.

As a leader in electrical power engineering, we help utilities, developers, and EPCs across the U.S. overcome modern grid challenges. Our expert electrical engineering team specializes in grid reliability, interconnection, and compliance.

About Keentel Engineering

Your Trusted Partner in Electrical Engineering and Power Systems

At Keentel Engineering, we deliver electrical power engineering services built on 30 years of experience and a commitment to excellence. Our clients include utilities, developers, EPCs, and public agencies across the U.S.

Unlike firms that sacrifice technical depth to chase billable hours, we prioritize precision, compliance, and value engineering. From transmission services and relay modeling to winterization and SCADA planning, we never compromise on quality.

Let's Discuss How to Optimize Your Next Project

Submit

We will get back to you as soon as possible.

Please try again later.

NERC Level 3 Alert Engineering Support

We specialize in NERC Level 3 Alert compliance services, helping U.S.-based generator owners meet evolving reliability standards. Our team stays ahead of regulatory developments, offering you peace of mind and technical accuracy in every submission.

Our Electrical Engineering Services

Our Electrical engineering team offers a wide range of services. We are a U.S. based electrical engineering and power engineering company with a focus on engineering, procurement, construction and associated regulatory compliance. We provide full-spectrum electrical engineering services focused on grid modernization, power system reliability, and renewable energy integration. Our electrical power engineering team supports projects from design through commissioning, helping clients meet NERC, IEEE, and state-level standards efficiently.

POI Interconnection Engineering Support

Our skilled and knowledgeable engineering team has a rich history in designing, developing and commissioning various substation and interconnection engineering support projects.

POI Interconnection Engineering Support

Our skilled and knowledgeable engineering team has a rich history in designing, developing and commissioning various substation and interconnection engineering support projects.

Substation Design

Services

At Keentel Engineering, we are experts in substation and interconnection engineering support services. Our experienced and knowledgeable team has a solid history in engineering, developing,…

EHV, HV. MV Power System Studies

Ensure electrical safety, minimize downtime, and meet compliance standards with our expert power system studies across Extra High Voltage (EHV), High Voltage (HV), and Medium…

POI Interconnection Engineering Support

Our skilled and knowledgeable engineering team has a rich history in designing, developing and commissioning various substation and interconnection engineering support projects.

Owner’s Engineer

Services

At Keentel Engineering, we specialize in providing comprehensive owner's engineer services tailored to meet your project's unique needs. With a commitment to

excellence and a…

NERC O&P 693 Compliance Services

At Keentel Engineering, our NERC compliance consultants specialize in helping power sector clients meet NERC 693 standards, including all aspects of O&P and RSAW

requirements.…

Utility Scale Solar Farm Engineering

Welcome to our comprehensive suite of electrical engineering services designed specifically for utility-scale solar farms. Our dedicated team of experienced professionals is committed to delivering…

Electrical Power System Engineering with Precision, Compliance & Results

At Keentel Engineering, we don’t just design systems—we engineer certainty. With over 27 years of experience in electrical engineering and power systems engineering, our firm supports critical infrastructure across the U.S., helping GOs, TOs, utilities, developers, EPCs, and public agencies meet the evolving demands of a modern grid.

We specialize in solving complex power challenges—bringing together compliance, technical depth, and engineering accuracy to every MV, HV, and EHV project. Whether you're advancing renewable energy, integrating utility-scale generation, or strengthening transmission assets, our expertise ensures performance under pressure.

As a leading electrical systems engineering company, Keentel is trusted nationwide for:

- Grid-ready designs rooted in field experience

- Deep understanding of IEEE, NERC, and PJM standards

- Expert modeling with ETAP, SKM, PSCAD, and GIS tools

- Real-world insights into winterization, emergency support, and public-sector operations

From power system engineering design to fault studies and relay coordination, Keentel combines engineering fundamentals with cutting-edge simulation and automation.

We support compliance and modeling services for:

- NERC Alerts and RSAW audits

- IEC 61850 implementation and SCADA integration

- HVDC system consulting for modernized transmission

- Grid interconnection queue navigation for utility-scale solar, wind, and BESS

- ETAP and SKM load study services aligned with utility and code requirements

Why Choose Keentel Engineering?

At Keentel Engineering, we take pride in being the go-to Electrical Power engineering firm for power and utility system planning, design, control, and analysis. Some of the many attributes of our company that set us apart are:

Client-Focused Work Approach

We work collaboratively from design and modeling to commissioning, ensuring we understand your goals and deliver tailored power system engineering services.

30 Years of Experience

Our team brings decades of success in power system interconnection, transmission line design, and renewable energy engineering — including BESS, solar PV, and wind.

Attention-to-Detail

We approach each project with detailed modeling, relay coordination, and fault analysis, delivering results that meet or exceed regulatory and performance benchmarks.

Quality with Innovation + Compliance

Whether you need ETAP, PSCAD, or SKM load studies, DIgSILENT simulations, or IEC 61850 automation solutions, we provide cutting-edge support with a compliance-first mindset.

AutoCAD

27+ Years

DIgSILENT

8+ Years

ETAP

15+ Years

PSSE

14+ Years

Bentley

14+ Years

SEL

27+ Years

EasyPower

10+ Years

PSCAD

5+ Years

SKM PowerTools

15+ Years

Cyme

27+ Years

Blog and Updates

Keentel Engineering is your trusted partner for reliable and compliant power system solutions across the U.S. Whether you're searching for electrical engineers, power system engineering services, or transmission and relay support, our experienced team delivers expert consulting in wind, solar, BESS, and substation design. We specialize in NERC compliance, winterization, and modeling support to meet your project’s most critical technical and regulatory needs.

Keentel Engineering at RE+ Las Vegas 2025!

We’re proud to announce that Keentel Engineering will be showcasing our expertise in renewable energy, substation design, NERC compliance, and advanced power system studies at RE+ 2025 in Las Vegas, September 8–11, 2025. Visit us at Booth #1423 to learn how we’re powering the future of reliable and compliant energy systems.