A Coordinated Electric System Interconnection Review—the utility’s deep-dive on technical and cost impacts of your project.

Challenge: Frequent false tripping using conventional electromechanical relays

Solution: SEL-487E integration with multi-terminal differential protection and dynamic inrush restraint

Result: 90% reduction in false trips, saving over $250,000 in downtime

| Category | Metric |

|---|---|

| VPP capacity (Lunar Energy) | 650 MW |

| Lunar funding raised | US$232 million |

| Data center BESS example | 31 MW / 62 MWh |

| ERCOT grid-scale batteries | 15+ GW |

| LDES tenders (H1 2026) | Up to 9.3 GW |

| Lithium-ion share of LDES by 2030 | 77% |

| FEOC initial threshold | 55% |

| BESS tariff rate (2026) | ~55% |

| Capacity gain from analytics | 5–15% |

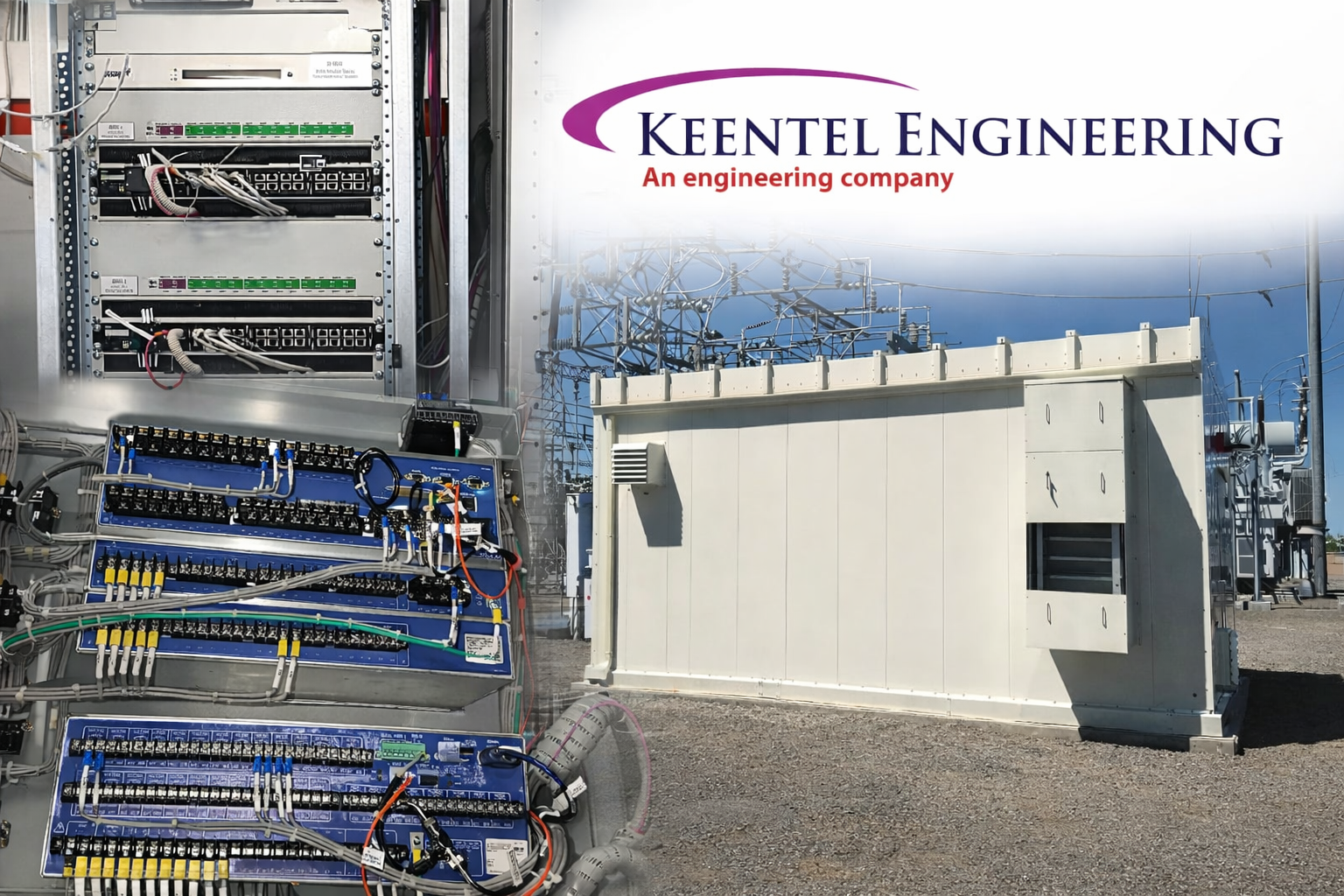

Owner’s Engineer Services in Energy & Power Infrastructure

February 21, 2026 | Blog

How Keentel Engineering Safeguards Your Investment from Concept to Commissioning

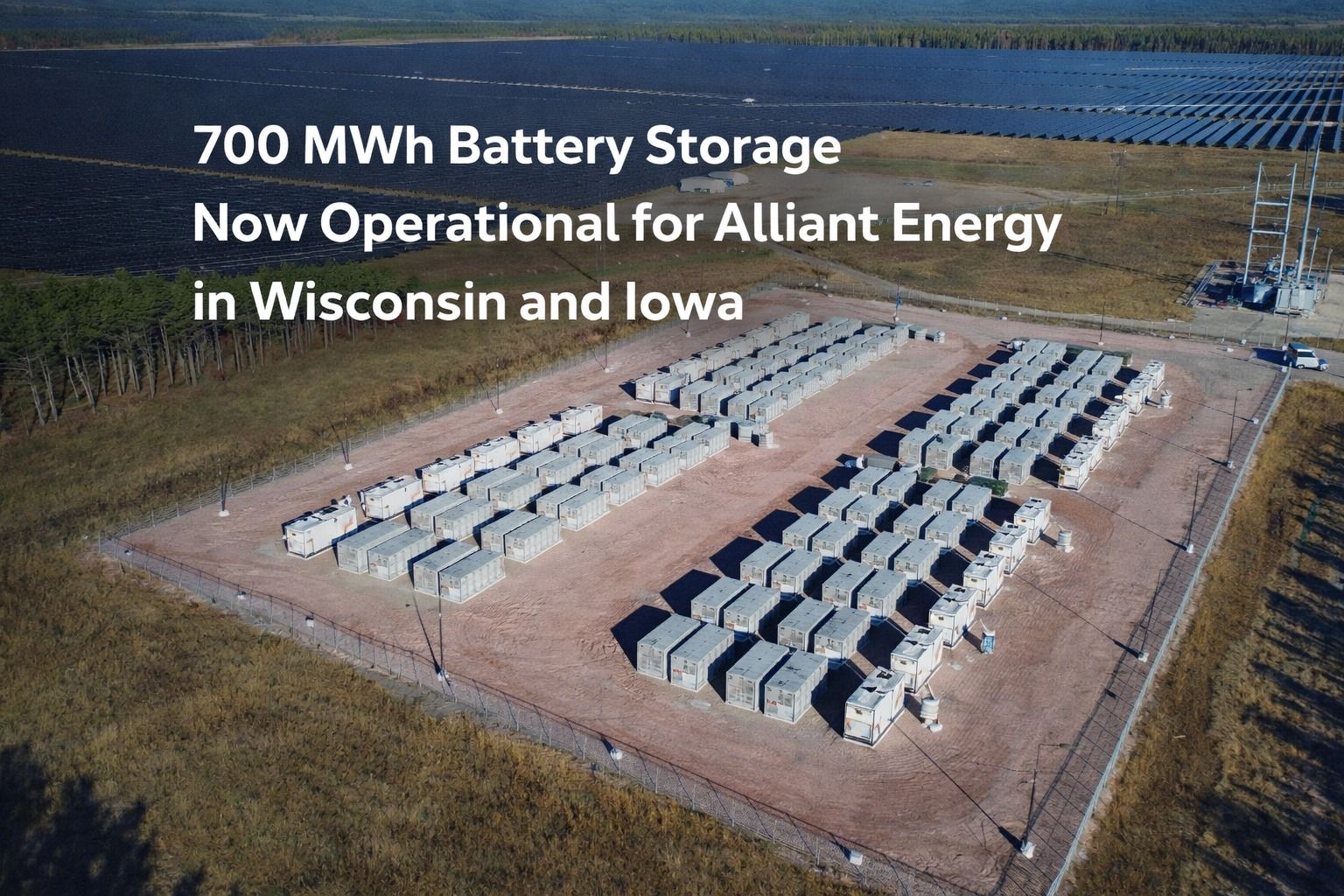

Large-scale renewable energy and power infrastructure projects are complex, capital-intensive, and highly regulated. Whether developing a utility-scale solar farm, battery energy storage system (BESS), high-voltage substation, transmission line, or industrial power facility, project owners face significant technical, financial, and regulatory risks.

Engineering, Procurement, and Construction (EPC) contractors are responsible for delivering the project. But who protects the owner’s interests?

This is where Owner’s Engineer (OE) services become critical.

Keentel Engineering provides independent, technically rigorous Owner’s Engineering services that safeguard quality, schedule, performance, and compliance ensuring that projects are delivered according to design intent, contractual obligations, and long-term operational goals.

What Is an Owner’s Engineer?

An Owner’s Engineer (OE) in electrical engineering acts as an independent technical representative of the project owner. Unlike EPC contractors or design consultants who execute specific scopes of work, the Owner’s Engineer serves as the owner's trusted technical authority across the entire project lifecycle:

- Feasibility & development

- Detailed engineering review

- Procurement evaluation

- Construction oversight

- Commissioning & performance validation

- Final handover

The OE is not a contractor.

The OE does not build the project.

The OE protects the owner.

For renewable energy, substation, and transmission projects, this independent oversight is often the difference between a successful asset and a costly underperforming facility.

Why Renewable Energy Projects Require Owner’s Engineering

Renewable energy projects especially utility-scale solar, wind, and battery storage involve:

- Multi-vendor equipment integration

- Grid interconnection requirements

- Complex protection & control schemes

- SCADA and EMS integration

- NERC and ISO compliance obligations

- Performance guarantees tied to financing

Each phase introduces technical and commercial risks.

Without independent technical oversight:

- Design errors may go undetected

- Equipment may not meet performance guarantees

- Interconnection compliance may fail

- Commissioning delays can escalate costs

- Long-term operational inefficiencies may arise

Keentel Engineering’s Owner’s Engineering services provide the structured technical governance required to safeguard large capital investments.

Core Responsibilities of an Owner’s Engineer

1. Design Review & Optimization

One of the most critical OE functions is the independent review of engineering designs prepared by EPC contractors.

Keentel Engineering reviews:

- Single Line Diagrams (SLDs)

- Substation layouts

- Protection & control schemes

- Relay settings philosophy

- Grounding design

- Cable sizing and routing

- PV array and DC string layouts

- BESS integration architecture

- SCADA network topology

- Power system studies (short circuit, load flow, stability)

We ensure designs:

- Meet IEEE, NEC, NESC, and NERC standards

- Align with ISO interconnection requirements (ERCOT, PJM, CAISO, SPP, MISO)

- Support long-term reliability

- Optimize CapEx and OpEx

- Reduce lifecycle maintenance risks

Optimization at the design stage prevents expensive rework during construction.

2. Technical Oversight During Construction

Construction is where design meets reality.

Keentel Engineering provides field-level technical supervision to ensure:

- Installation follows approved drawings

- Equipment matches technical specifications

- Electrical clearances meet code

- Protection wiring is correct

- Transformers are installed per manufacturer requirements

- Switchgear and breaker alignment is verified

- Inverter commissioning aligns with grid-code performance requirements

For example, in a utility-scale solar farm:

- Tracker geometry and alignment are validated

- DC cable routing and combiner placement are verified

- Inverter grounding and harmonic filtering are assessed

- Substation transformer protection wiring is checked

- Relay testing is witnessed

If issues arise such as delayed transformer delivery, improper cable derating, or incorrect CT polarity Keentel’s OE team intervenes early to prevent cascading schedule impacts.

3. Quality Assurance & Compliance Monitoring

Renewable and grid-connected projects must comply with:

- NEC

- IEEE standards

- NERC PRC/TPL requirements

- ISO interconnection standards

- Utility technical requirements

- Local building and electrical codes

Owner’s Engineering provides independent quality control and compliance validation.

We conduct:

- Site inspections at critical milestones

- FAT (Factory Acceptance Test) oversight

- SAT (Site Acceptance Test) supervision

- Relay testing verification

- Protection scheme validation

- Commissioning procedure review

- Documentation traceability audits

This ensures regulatory alignment and supports lender technical due diligence.

4. Interface Management Across Disciplines

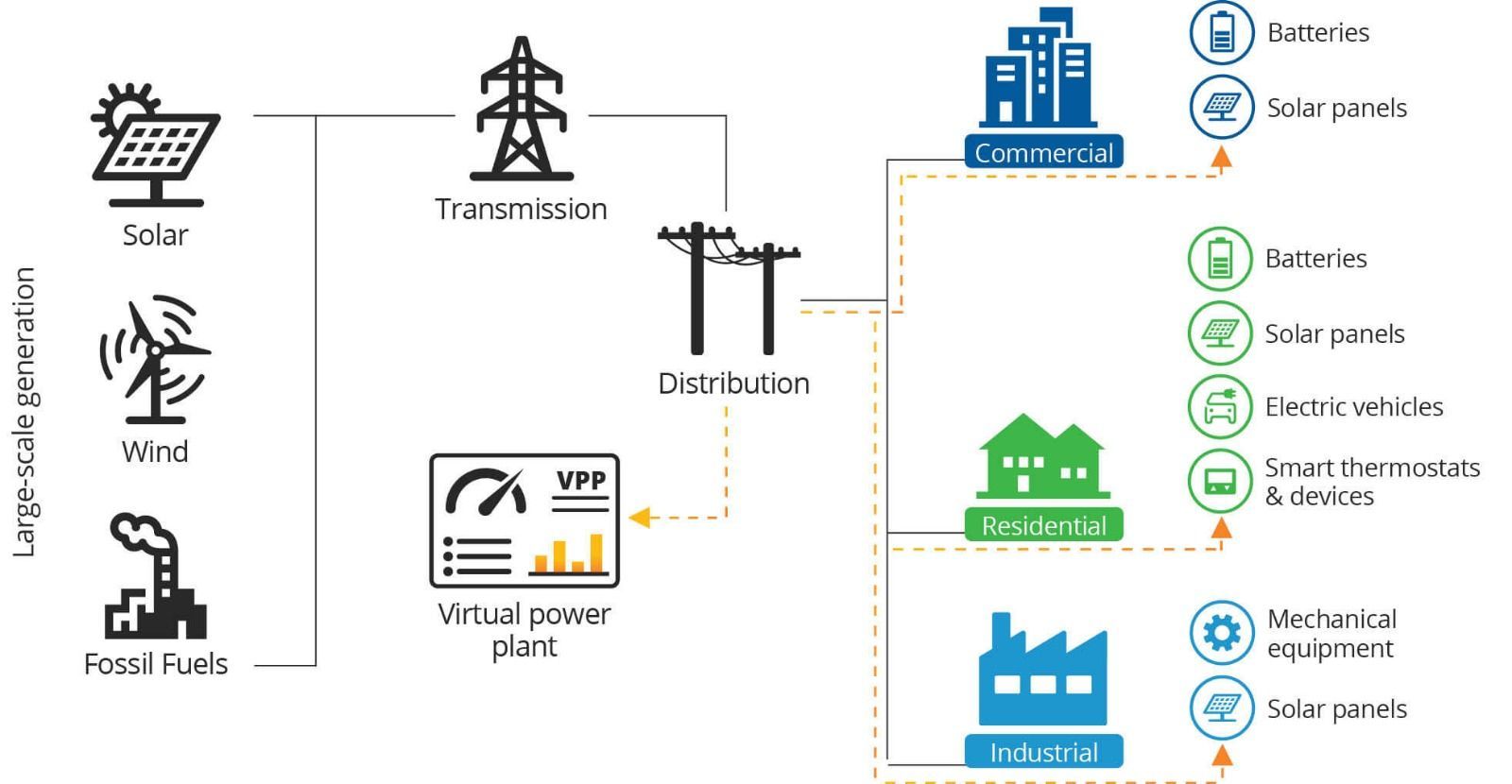

Renewable projects integrate multiple systems:

- PV arrays

- Inverters

- BESS

- Substation equipment

- Protection relays

- SCADA and communication networks

- Civil and structural components

Failures often occur at system interfaces.

Keentel Engineering manages:

- Electrical-mechanical interfaces

- Protection-SCADA integration

- EMS-inverter communication protocols

- Substation-grid interconnection logic

- Battery-inverter performance coordination

In BESS projects, for example, we verify:

- Communication between Energy Management System (EMS) and inverter

- Protection settings coordination

- Grid-code ride-through capability

- Harmonic compliance

Proper interface management prevents system incompatibility and performance penalties.

5. Risk Mitigation & Technical Assurance

Owner’s Engineering reduces risk exposure in:

- Design integrity

- Construction quality

- Schedule adherence

- Regulatory compliance

- Performance guarantees

Key benefits include:

- Early detection of technical flaws

- Reduced rework costs

- Improved stakeholder coordination

- Independent reporting for investors

- Enhanced long-term asset reliability

For projects financed through tax equity, debt funding, or infrastructure investment, independent OE oversight adds credibility and transparency.

Owner’s Engineer vs Consultant vs EPC

Understanding the distinction is critical.

| Role | Scope | Primary Responsibility |

|---|---|---|

| EPC Contractor | Design & Build | Deliver project per contract |

| Consultant | Specific technical task | Provide defined expertise |

| Owner’s Engineer | Entire lifecycle | Protect owner’s interests |

The Owner’s Engineer remains engaged from concept to commissioning ensuring continuity, accountability, and alignment with owner objectives.

Keentel Engineering acts as an extension of your internal technical team.

Required Expertise of a High-Level Owner’s Engineer

An effective OE must possess:

Education

- Bachelor’s or Master’s in Electrical Engineering

- Professional Engineering (P.E.) licensure (where required)

Technical Experience

- HV/MV substation design

- Transmission line engineering

- Renewable interconnection studies

- Protection & control systems

- NERC compliance programs

- Power system modeling (PSSE, PSCAD, DigSILENT)

Regulatory Knowledge

- NEC

- IEEE standards

- NERC PRC/TPL/GMD

- ISO interconnection manuals

Soft Skills

- Independent judgment

- Contract interpretation

- Risk communication

- Construction coordination

- Executive reporting

Keentel Engineering combines all of these capabilities under one integrated technical team.

Keentel Engineering: A Trusted Owner’s Engineer Across the U.S.

Keentel Engineering provides Owner’s Engineering services for:

- Utility-scale solar projects

- Battery Energy Storage Systems (BESS)

- HV & EHV substations

- Transmission lines

- Industrial power systems

- Grid interconnection projects

- NERC compliance initiatives

We operate across U.S. markets including ERCOT, PJM, CAISO, SPP, and MISO, ensuring ISO-specific technical alignment.

Our experience spans:

- Substation primary & secondary design

- Protection & control system development

- Relay settings validation

- SCADA architecture

- Power system studies

- Grid code compliance

- Commissioning support

We are independent, technically rigorous, and owner-focused.

How Owner’s Engineering Protects Long-Term Asset Value

The impact of OE services extends beyond construction.

Proper oversight ensures:

- Reliable system performance

- Reduced forced outages

- Accurate relay coordination

- Optimized transformer loading

- Reduced maintenance costs

- Compliance audit readiness

- Extended asset lifespan

In renewable energy projects with 20- to 30-year operating horizons, these benefits compound significantly.

Why Independent Oversight Matters in Renewable Energy

Solar and BESS projects involve tight commercial schedules and performance guarantees tied to:

- Capacity ratings

- Availability metrics

- Energy yield

- Grid-code compliance

Without an Owner’s Engineer:

- EPC incentives may not align with long-term performance

- Design shortcuts may reduce reliability

- Interface issues may emerge during commissioning

- Warranty disputes may arise

Keentel Engineering provides independent validation that ensures technical integrity and protects owner investment.

Conclusion: The Strategic Value of Owner’s Engineering

Renewable energy and grid infrastructure projects are too complex and capital-intensive to rely solely on EPC execution.

An Owner’s Engineer:

- Protects your investment

- Ensures regulatory compliance

- Validates technical performance

- Reduces lifecycle risk

- Aligns project execution with strategic objectives

Keentel Engineering serves as your trusted technical authority delivering independent, expert Owner’s Engineering services that safeguard quality, schedule, safety, and long-term asset performance.

Contact Keentel Engineering

If you are developing a renewable energy, substation, transmission, or industrial power project and require independent technical oversight, Keentel Engineering is ready to support your success.

Protect your investment. Ensure technical excellence. Deliver with confidence.

25 Technical FAQs – Owner’s Engineer Services (SEO Optimized)

1. What is an Owner’s Engineer in renewable energy projects?

An Owner’s Engineer (OE) is an independent electrical engineering expert who represents the project owner’s interests throughout the lifecycle of renewable energy projects, ensuring compliance, quality, performance, and adherence to budget and schedule.

2. Why do solar and BESS projects require an Owner’s Engineer?

Utility-scale solar and battery energy storage systems (BESS) involve complex interconnection, protection, SCADA, and compliance requirements. An OE mitigates technical risk, verifies EPC performance, and protects long-term asset value.

3. What is the difference between an EPC contractor and an Owner’s Engineer?

An EPC contractor designs and builds the project. The Owner’s Engineer independently reviews, verifies, and oversees the EPC’s work to ensure it meets the owner’s technical and contractual expectations.

4. When should an Owner’s Engineer be engaged?

Ideally during the early feasibility and development phase, before detailed engineering begins. Early engagement reduces design errors, cost overruns, and compliance risks.

5. What technical documents does an Owner’s Engineer review?

- Single Line Diagrams (SLDs)

- Protection & control schematics

- Relay settings philosophy

- Grounding studies

- Short circuit and load flow studies

- SCADA architecture

- Equipment specifications

- Grid interconnection studies

6. How does an Owner’s Engineer support grid interconnection compliance?

The OE ensures compliance with ISO/RTO requirements (ERCOT, PJM, CAISO, SPP, MISO), IEEE standards, and NERC reliability standards through independent study validation and performance verification.

7. Does an Owner’s Engineer perform power system studies?

Yes. OE teams review or independently validate load flow, short circuit, arc flash, stability, EMT, and harmonic studies to ensure system performance and regulatory compliance.

8. How does an Owner’s Engineer reduce CapEx and OpEx?

By optimizing equipment selection, reviewing overdesign or underdesign conditions, and ensuring lifecycle reliability, the OE reduces rework, downtime, and maintenance costs.

9. What role does the OE play during construction?

The OE monitors installation quality, verifies equipment compliance, witnesses testing (FAT/SAT), resolves field issues, and ensures alignment between approved design and field execution.

10. What is FAT and SAT in Owner’s Engineering?

- FAT (Factory Acceptance Test): Equipment testing before shipment.

- SAT (Site Acceptance Test): Equipment testing after installation.

The OE witnesses and validates both to ensure performance compliance.

11. How does an Owner’s Engineer support NERC compliance?

The OE ensures protection systems, relay settings, disturbance monitoring, and documentation meet NERC PRC, TPL, and other applicable standards.

12. What industries benefit from Owner’s Engineering services?

- Utility-scale solar

- Battery Energy Storage Systems (BESS)

- Wind farms

- HV/EHV substations

- Transmission lines

- Industrial facilities

- Data centers

- Microgrids

13. Does the Owner’s Engineer manage contractor disputes?

Yes. The OE provides technical evaluation of variation orders, change requests, and claims, protecting the owner from unjustified cost increases.

14. What standards must an Owner’s Engineer understand?

- NEC

- IEEE

- NESC

- NERC standards

- ISO/RTO interconnection manuals

- Utility-specific requirements

15. How does an Owner’s Engineer improve project schedule certainty?

By identifying design deficiencies early, managing technical interfaces, and ensuring milestone alignment, the OE prevents delays caused by engineering or compliance failures.

16. What is interface management in renewable energy projects?

Interface management ensures coordination between PV arrays, inverters, BESS, substations, SCADA, and grid interconnection systems to prevent operational conflicts.

17. Can an Owner’s Engineer review relay protection coordination?

Yes. The OE reviews relay settings, coordination studies, fault current calculations, and protection philosophies to ensure reliability and selectivity.

18. How does an OE validate inverter performance?

By reviewing grid-code compliance testing, ride-through capability, harmonic distortion, and dynamic response under system disturbances.

19. Is an Owner’s Engineer required for lender technical due diligence?

Often yes. Lenders rely on independent OE validation to assess technical risk before financing large renewable energy projects.

20. What is technical assurance in renewable projects?

Technical assurance refers to independent verification that engineering, procurement, and construction meet performance, regulatory, and safety requirements.

21. Does the OE assist during commissioning?

Yes. The OE oversees energization procedures, commissioning protocols, relay testing, SCADA validation, and performance acceptance criteria.

22. How does Owner’s Engineering improve long-term asset reliability?

Through proper grounding, protection coordination, transformer loading validation, and system optimization, reducing forced outages and equipment stress.

23. What software tools are used by Owner’s Engineers?

- PSSE

- PSCAD

- DigSILENT PowerFactory

- ETAP

- SKM

- MATLAB/Simulink

- HYPERSIM / RTDS (for advanced modeling)

24. Can an Owner’s Engineer support battery storage compliance?

Yes. The OE verifies EMS communication, protection coordination, harmonic performance, and interconnection compliance for BESS facilities.

25. Why choose Keentel Engineering as your Owner’s Engineer?

Keentel Engineering combines deep expertise in renewable energy, HV/MV substations, protection & control, transmission systems, and NERC compliance — delivering independent, technically rigorous oversight across the United States.

Case Studies

Case Study 1: 200 MW Utility-Scale Solar + 50 MWh BESS (ERCOT)

Challenge

A developer faced schedule pressure and grid compliance risk during late-stage EPC design. Concerns arose regarding inverter ride-through capability and relay coordination.

Keentel’s Role

- Independent design review of SLD and protection philosophy

- Validation of load flow and short circuit studies

- EMT-level review of inverter grid-code compliance

- FAT witness for main power transformer and inverters

- SAT oversight during commissioning

Findings

- Incorrect CT ratio impacting relay coordination

- Harmonic distortion levels exceeding ERCOT threshold

- Incomplete grounding grid design

Outcome

- Design corrected prior to energization

- Interconnection approval achieved without delay

- Zero post-commissioning protection misoperations

- Long-term performance guarantee preserved

Case Study 2: 345 kV Substation Expansion (PJM Territory)

Challenge

EPC proposed value-engineered modifications to protection scheme affecting NERC PRC compliance.

Keentel’s Role

- Protection coordination review

- Breaker failure scheme validation

- NERC PRC compliance audit preparation

- On-site commissioning oversight

Findings

- Misaligned breaker failure timer settings

- Incomplete disturbance monitoring documentation

Outcome

- PRC compliance maintained

- Avoided potential NERC violation penalties

- Successful energization within schedule

Case Study 3: 150 MW Solar Farm – Construction Quality Risk (SPP)

Challenge

Site inspections revealed inconsistencies in tracker installation and cable trenching depth.

Keentel’s Role

- Field inspection and milestone verification

- Cable ampacity validation

- Combiner box grounding inspection

- Variation order review

Findings

- Undersized cable for ambient temperature conditions

- Improper grounding bond at combiner panels

Outcome

- Immediate corrective action issued

- Prevented overheating and future reliability issues

- Reduced long-term maintenance risk

Case Study 4: 100 MWh Standalone BESS Facility (CAISO)

Challenge

Complex EMS-inverter integration issues during commissioning.

Keentel’s Role

- Interface management between EMS, SCADA, and inverter vendor

- Grid-code compliance validation

- SAT testing oversight

Findings

- Communication latency affecting dispatch response

- Incorrect frequency droop settings

Outcome

- Communication architecture optimized

- Grid compliance achieved

- Commercial operation date met without penalty

Case Study 5: Industrial Facility 138 kV Interconnection (MISO)

Challenge

Owner required independent validation of EPC’s arc flash and short circuit study before energization.

Keentel’s Role

- Independent study verification using ETAP

- Protection coordination analysis

- Transformer inrush and fault current modeling

- Commissioning procedure review

Findings

- Arc flash labeling discrepancies

- Relay pickup values misaligned with coordination curves

Outcome

- Corrected protection settings prior to energization

- Improved worker safety compliance

- Successful commissioning with no safety incidents

Closing Statement

These projects demonstrate how Keentel Engineering’s Owner’s Engineer services:

- Reduce technical and regulatory risk

- Improve schedule certainty

- Safeguard performance guarantees

- Enhance long-term reliability

- Protect multi-million-dollar capital investments

About the Author:

Sonny Patel P.E. EC

IEEE Senior Member

In 1995, Sandip (Sonny) R. Patel earned his Electrical Engineering degree from the University of Illinois, specializing in Electrical Engineering . But degrees don’t build legacies—action does. For three decades, he’s been shaping the future of engineering, not just as a licensed Professional Engineer across multiple states (Florida, California, New York, West Virginia, and Minnesota), but as a doer. A builder. A leader. Not just an engineer. A Licensed Electrical Contractor in Florida with an Unlimited EC license. Not just an executive. The founder and CEO of KEENTEL LLC—where expertise meets execution. Three decades. Multiple states. Endless impact.

Services

Let's Discuss Your Project

Let's book a call to discuss your electrical engineering project that we can help you with.

About the Author:

Sonny Patel P.E. EC

IEEE Senior Member

In 1995, Sandip (Sonny) R. Patel earned his Electrical Engineering degree from the University of Illinois, specializing in Electrical Engineering . But degrees don’t build legacies—action does. For three decades, he’s been shaping the future of engineering, not just as a licensed Professional Engineer across multiple states (Florida, California, New York, West Virginia, and Minnesota), but as a doer. A builder. A leader. Not just an engineer. A Licensed Electrical Contractor in Florida with an Unlimited EC license. Not just an executive. The founder and CEO of KEENTEL LLC—where expertise meets execution. Three decades. Multiple states. Endless impact.

Leave a Comment

We will get back to you as soon as possible.

Please try again later.