A Coordinated Electric System Interconnection Review—the utility’s deep-dive on technical and cost impacts of your project.

Challenge: Frequent false tripping using conventional electromechanical relays

Solution: SEL-487E integration with multi-terminal differential protection and dynamic inrush restraint

Result: 90% reduction in false trips, saving over $250,000 in downtime

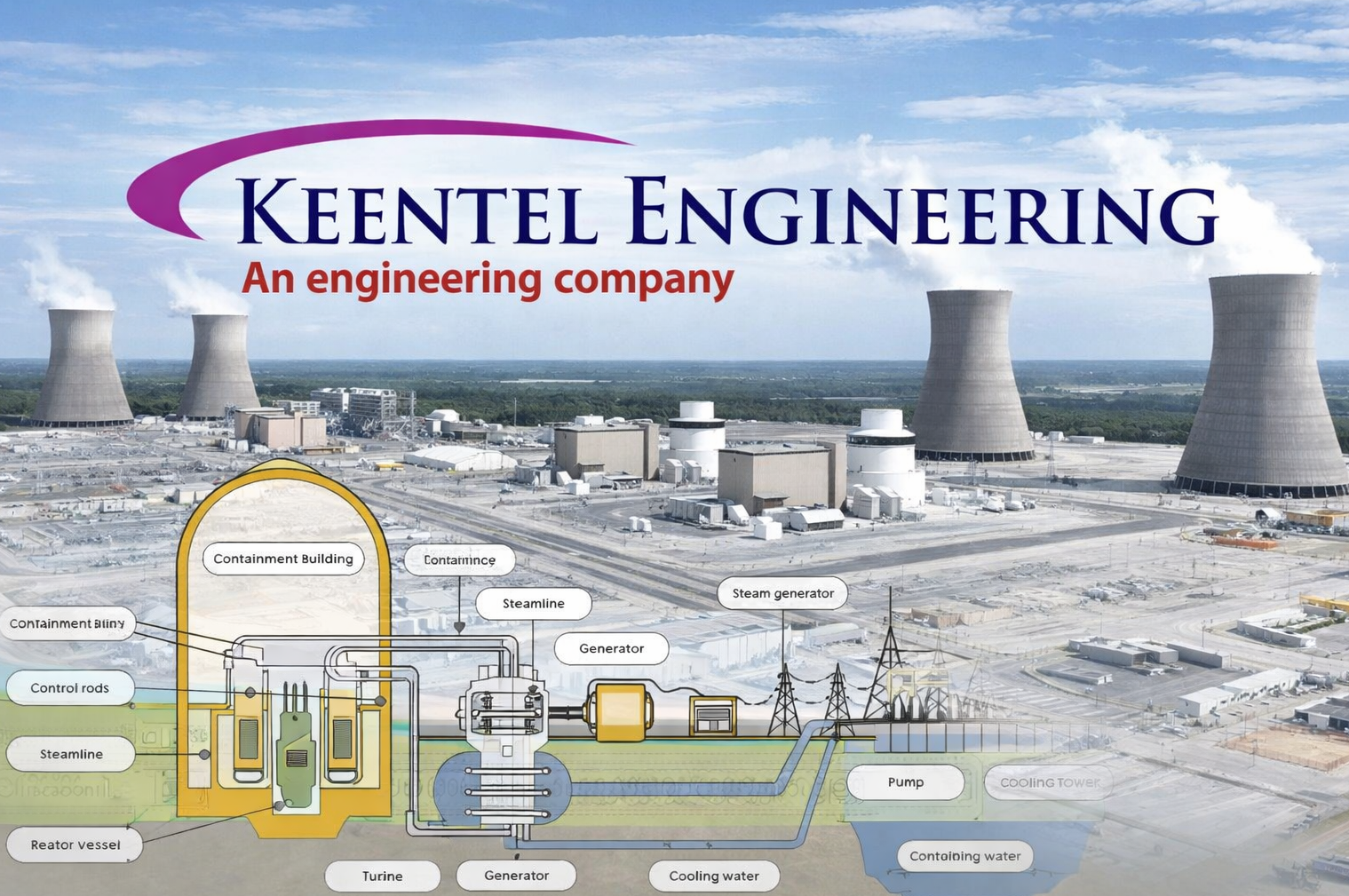

Electrical Systems in Nuclear Power Plants: Design, Safety, and Compliance Considerations

February 04, 2026 | Blog

Introduction

Electrical systems form the backbone of nuclear power plant safety, reliability, and operational continuity. Unlike conventional power plants, nuclear facilities impose extraordinary requirements on electrical power systems to ensure reactor safety, containment integrity, and compliance with stringent regulatory frameworks. From normal operation to extreme accident scenarios, electrical systems must perform predictably, independently, and without common-cause failure.

This article explores the architecture, safety classifications, redundancy philosophies, and regulatory drivers governing electrical systems in nuclear power plants, with a particular focus on Class 1E power systems, emergency power supplies, containment penetrations, and grid interface considerations.

Role of Electrical Systems in Nuclear Plant Safety

In nuclear facilities, electrical systems are not merely support infrastructure—they are safety-critical systems. Key safety functions dependent on electrical power include:

- Reactor shutdown (SCRAM)

- Core cooling and heat removal

- Containment isolation

- Instrumentation and control (I&C)

- Emergency lighting and communications

- Actuation of engineered safety features

Loss or degradation of electrical power can escalate plant conditions rapidly, which is why nuclear electrical designs are governed by defense-in-depth principles and single-failure criteria

Electrical-Systems-for-Nuclear-…

Classification of Nuclear Power Plant Electrical Systems

Safety-Related vs Non-Safety-Related Systems

Electrical systems in nuclear plants are broadly divided into:

- Safety-related (Class 1E) systems

- Non-safety-related systems

Class 1E systems are those required to function during design-basis events and accidents to prevent or mitigate radiological consequences.

Class 1E Electrical Power Systems

Definition and Purpose

Class 1E electrical systems are designed to perform essential safety functions under all credible operating and accident conditions, including:

- Loss of off-site power

- Station blackout

- Seismic events

- Flooding and fire scenarios

- Loss-of-coolant accidents (LOCA)

These systems include:

- Class 1E AC power distribution

- Class 1E DC power systems

- Instrumentation and control power

- Electrical containment penetrations

Key Design Requirements for Class 1E Systems

1. Redundancy and Independence

- Multiple independent power divisions

- Physical and electrical separation

- No single failure may disable all safety functions

2. Single Failure Criterion

Each safety function must be achievable despite the failure of any single active component, whether electrical, mechanical, or control-related

Electrical-Systems-for-Nuclear-…

3. Qualified Equipment

All Class 1E equipment must be:

- Environmentally qualified

- Seismically qualified

- Tested for aging, radiation, temperature, pressure, and chemical exposure

On-Site Emergency AC Power Sources

Emergency Diesel Generators (EDGs)

Emergency diesel generators serve as the primary on-site AC backup power source following loss of off-site power. Critical requirements include:

- Automatic start and load acceptance

- Fast response time

- Capability to power safety loads independently

- Periodic surveillance and load testing

EDGs must be capable of supporting full safety load sequencing, including large motor starting without unacceptable voltage dips.

DC Power Systems and Energy Storage

Role of DC Systems

DC power systems provide:

- Control power for breakers and relays

- Power for protection systems

- Instrumentation and control reliability

- Short-term power during transition events

Battery systems are typically designed to supply power for extended periods during station blackout conditions, ensuring operators retain control and visibility.

Instrumentation and Control Power Systems

Reliability Requirements

Instrumentation and control systems rely on highly stable, noise-free power sources. Design considerations include:

- Redundant DC supplies

- Isolation from non-safety systems

- Harmonic mitigation

- Continuous monitoring and alarm indication

Loss of I&C power is treated as a major safety concern due to its impact on situational awareness and automated protection.

Containment Electrical Penetration Assemblies (EPAs)

Purpose and Safety Function

Containment electrical penetrations allow electrical conductors to pass through containment boundaries without compromising pressure integrity or leak tightness.

Key requirements include:

- Leak rate limits

- Fire resistance

- Pressure and temperature qualification

- LOCA survivability

- Continuous monitoring capability

Failure of a penetration must not result in containment breach or loss of safety functions

Electrical-Systems-for-Nuclear-…

Interface Between Nuclear Plants and the Grid

Off-Site Power Importance

Off-site power is considered the preferred power supply, supporting:

- Normal operation

- Safe shutdown

- Emergency system readiness

Nuclear plants typically require multiple independent off-site power circuits, designed to minimize simultaneous failure risks.

Station Blackout (SBO) Considerations

Station blackout represents one of the most severe electrical scenarios. Electrical designs must account for:

- Complete loss of off-site and on-site AC power

- Extended coping duration

- Alternate AC sources

- Load shedding and prioritization

- Operator training and procedures

Post-event industry experience has significantly strengthened SBO design requirements.

Aging, Life Extension, and Electrical Asset Management

Electrical systems must remain reliable over extended plant lifetimes, often exceeding original design expectations. Effective asset management includes:

- Condition monitoring

- Preventive maintenance

- Cable aging assessments

- Transformer and switchgear diagnostics

- Periodic testing and surveillance programs

Frequently Asked Questions (FAQ)

1. What makes electrical systems in nuclear plants different from conventional plants?

Nuclear electrical systems are safety-critical, must meet single-failure criteria, and must operate under extreme accident conditions while maintaining containment integrity.

2. What is a Class 1E electrical system?

Class 1E systems are safety-related electrical systems required to function during design-basis accidents to prevent or mitigate radiological consequences.

3. Why is redundancy required in nuclear electrical systems?

Redundancy ensures that no single failure can disable critical safety functions, supporting defense-in-depth safety philosophy.

4. How are emergency diesel generators tested?

EDGs undergo factory qualification, site acceptance testing, periodic surveillance testing, and full load testing to verify reliability.

5. Why are DC power systems critical in nuclear plants?

DC systems power protection relays, breaker controls, and instrumentation, especially during transitions or blackout conditions.

6. What is the single failure criterion?

It requires that safety systems perform their intended function even if one component fails during an accident.

7. How are electrical systems protected from fire?

Fire-resistant materials, cable separation, fire barriers, and compliance with nuclear fire protection standards are mandatory.

8. What happens if off-site power is lost?

On-site emergency power systems automatically start and supply safety loads to maintain reactor safety and cooling.

9. Why are containment electrical penetrations so critical?

They preserve containment pressure boundaries while allowing electrical connectivity, preventing radioactive release.

10. How long must nuclear electrical systems operate during emergencies?

Design requirements vary, but systems must support safe shutdown and cooling for extended durations, including station blackout coping periods.

About the Author:

Sonny Patel P.E. EC

IEEE Senior Member

In 1995, Sandip (Sonny) R. Patel earned his Electrical Engineering degree from the University of Illinois, specializing in Electrical Engineering . But degrees don’t build legacies—action does. For three decades, he’s been shaping the future of engineering, not just as a licensed Professional Engineer across multiple states (Florida, California, New York, West Virginia, and Minnesota), but as a doer. A builder. A leader. Not just an engineer. A Licensed Electrical Contractor in Florida with an Unlimited EC license. Not just an executive. The founder and CEO of KEENTEL LLC—where expertise meets execution. Three decades. Multiple states. Endless impact.

Services

Let's Discuss Your Project

Let's book a call to discuss your electrical engineering project that we can help you with.

About the Author:

Sonny Patel P.E. EC

IEEE Senior Member

In 1995, Sandip (Sonny) R. Patel earned his Electrical Engineering degree from the University of Illinois, specializing in Electrical Engineering . But degrees don’t build legacies—action does. For three decades, he’s been shaping the future of engineering, not just as a licensed Professional Engineer across multiple states (Florida, California, New York, West Virginia, and Minnesota), but as a doer. A builder. A leader. Not just an engineer. A Licensed Electrical Contractor in Florida with an Unlimited EC license. Not just an executive. The founder and CEO of KEENTEL LLC—where expertise meets execution. Three decades. Multiple states. Endless impact.

Leave a Comment

We will get back to you as soon as possible.

Please try again later.