A Coordinated Electric System Interconnection Review—the utility’s deep-dive on technical and cost impacts of your project.

Challenge: Frequent false tripping using conventional electromechanical relays

Solution: SEL-487E integration with multi-terminal differential protection and dynamic inrush restraint

Result: 90% reduction in false trips, saving over $250,000 in downtime

| Category | Metric |

|---|---|

| VPP capacity (Lunar Energy) | 650 MW |

| Lunar funding raised | US$232 million |

| Data center BESS example | 31 MW / 62 MWh |

| ERCOT grid-scale batteries | 15+ GW |

| LDES tenders (H1 2026) | Up to 9.3 GW |

| Lithium-ion share of LDES by 2030 | 77% |

| FEOC initial threshold | 55% |

| BESS tariff rate (2026) | ~55% |

| Capacity gain from analytics | 5–15% |

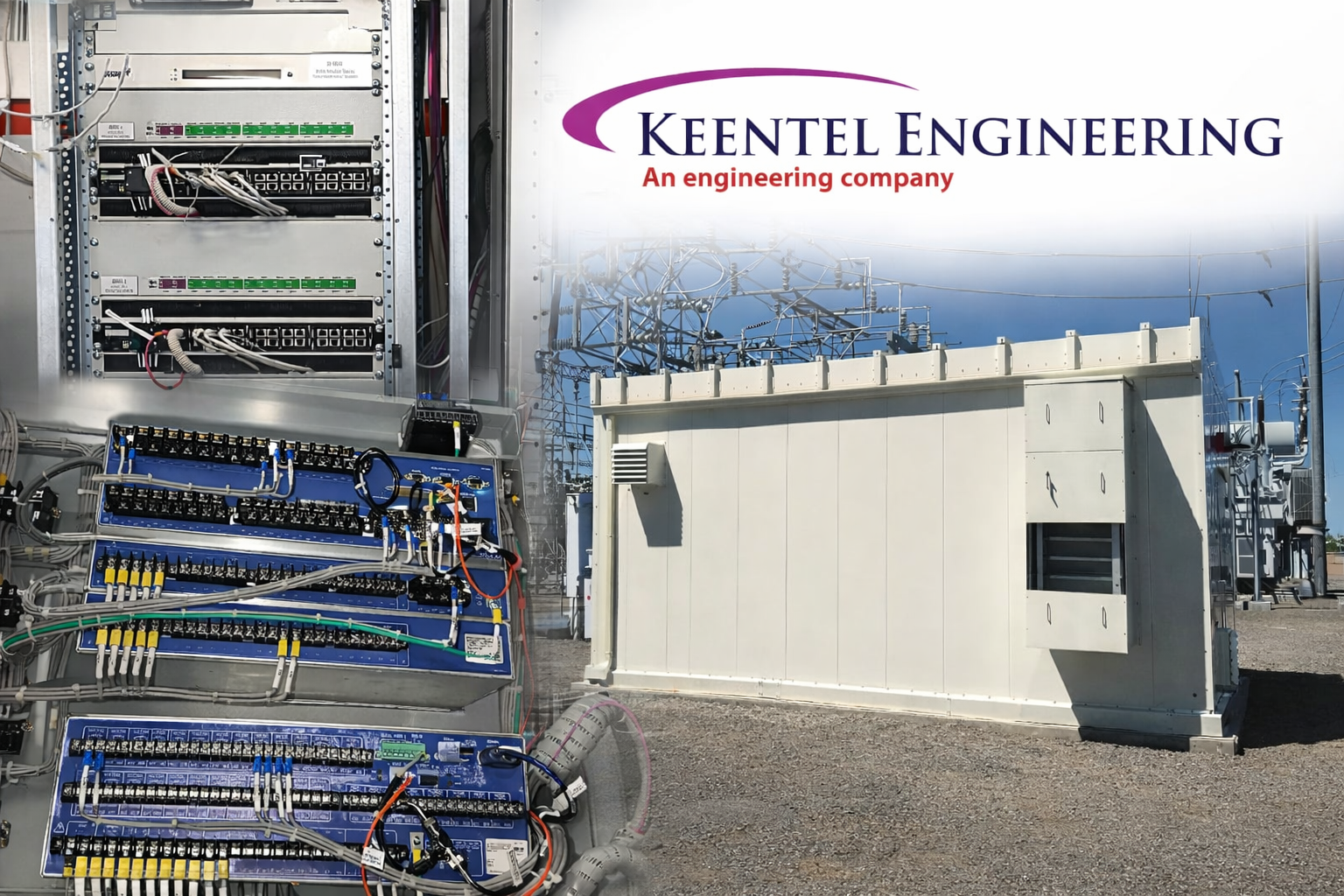

Substation Secondary Systems Design – Best Practices for Reliable, Safe, and Compliant Substations

February 08, 2026 | Blog

Introduction

Modern high-voltage substations are no longer defined only by primary equipment such as breakers, transformers, and buswork. The real intelligence of a substation lies in its secondary systems protection, control, metering, DC systems, communications, and auxiliary services. These systems ensure safe operation, fast fault clearing, regulatory compliance, and long-term reliability.

At Keentel Engineering, our substation design philosophy integrates proven industry practices with practical constructability, maintainability, and compliance considerations. This article is based on globally accepted engineering guidance for the installation and design of substation secondary equipment, translated into real-world design principles used by Keentel Engineering for utility, renewable, and industrial substations.

What Are Substation Secondary Systems?

Secondary systems are the functional backbone of a substation. They:

- Protect primary equipment from faults

- Enable control and switching operations

- Monitor system health and performance

- Ensure personnel safety

- Provide alarms, interlocking, and communications

Typical secondary systems include:

- Protective relays and automation systems

- DC battery and charger systems

- Control panels and relay panels

- Instrument transformer (CT/VT) circuits

- SCADA and communication systems

- Fire detection and auxiliary services

Separation of Substation-Level and Bay-Level Equipment

A fundamental principle in substation design is the logical and physical separation of secondary equipment:

Substation-Level Equipment

- SCADA master units

- Station alarms

- Central DC systems

- Global interlocking and control

Bay-Level Equipment

- Line, transformer, and feeder protection relays

- Local control and metering

- Breaker control circuits

For higher-voltage substations, Keentel Engineering often designs:

- Centralized control buildings for station-level systems

- Dispersed relay kiosks located close to primary equipment for bay-level systems

This approach minimizes CT/VT lead lengths, improves signal integrity, and reduces common-mode failure risks.

DC System Design – No Interruption Allowed

Secondary systems must remain operational during AC system faults. For this reason, DC systems are mission-critical.

Key DC Design Principles

- Battery-backed DC supply with charger

- Continuous operation during AC outages

- Voltage margins to guarantee breaker tripping

Industry-Standard Practices

- Duplicate DC systems for substations ≥ 220 kV

- Parallel battery and charger feeding the DC distribution board

- Typical operating voltage 10–12% above nominal

- Independent DC feeds for critical protection circuits

Battery Room Design

- Sealed batteries may share rooms with chargers

- Vented lead-acid batteries require:

- Dedicated rooms

- Fire-rated doors

- Acid-resistant flooring

- Adequate ventilation

Keentel Engineering designs DC systems that meet utility standards,

NERC reliability expectations, and long-term maintenance needs.

Redundant Protection – Group A and Group B Philosophy

Reliability in protection systems is achieved through redundancy.

Core Redundancy Rules

- Two fully independent protection groups

- Separate DC supplies

- Separate relay panels

- Separate CT cores

- Physically segregated cabling routes

Circuit Breaker Considerations

- Circuit breakers are typically not duplicated

- Dual trip coils are used

- Breaker failure protection is mandatory

This architecture ensures that a single failure—whether electrical, mechanical, or fire-related—does not disable protection for critical assets.

Instrument Transformer Circuit Design

Improper CT/VT design is a common cause of mis-operations. Keentel Engineering follows strict rules:

Current Transformers (CTs)

- Separate cores for Group A and Group B

- Dedicated CT cores for bus differential protection

- No shared current loops

- Proper burden calculations to ensure relay accuracy

Voltage Transformers (VTs)

- Separate secondary windings where available

- Separate fuse groups when windings are shared

- Clear segregation at marshalling kiosks

Relay Panel Layout and Physical Segregation

Panel design is not just drafting—it is risk management.

Best Practices

- Separate panels for redundant protection groups

- Clear labeling of circuits and protection zones

- Physical barriers between terminal groups

- Logical grouping of relays sharing the same DC source

Good panel design reduces commissioning errors, improves safety, and simplifies maintenance.

Cabling and Wiring Philosophy

Secondary cabling must support the full life cycle of the substation.

Design Objectives

- Ease of installation

- Simplified testing and commissioning

- Future expandability

- Fire risk mitigation

Cabling Best Practices

- Prefabrication where feasible

- Spare capacity in trenches and conduits

- Flame-retardant cable insulation

- Clear segregation between power, control, and communication cables

Environmental Control and Ventilation

Secondary equipment reliability depends heavily on environmental conditions.

Key Considerations

- Temperature control for electronic relays

- Adequate ventilation for battery rooms

- Anti-condensation heating

- Panel lighting for maintenance

Keentel Engineering evaluates site-specific climate conditions to determine optimal HVAC strategies.

Fire Detection and Protection in Substations

Fire protection is a critical yet often underestimated part of

substation design.

Fire Risk Mitigation Measures

- Cable segregation to avoid common-mode failures

- Fire-resistant barriers between critical systems

- Smoke detection zones

- Automatic and manual fire suppression

- Shutdown of HVAC systems upon fire detection

Fire systems are designed to be fully operational at commissioning, with trained personnel and clear emergency procedures.

Why Keentel Engineering for Substation Design?

Keentel Engineering brings decades of experience in:

- HV, EHV, and MV substation design

- Protection and control engineering

- Utility and renewable interconnections

- NERC, ISO, and utility compliance

Our designs balance technical rigor, constructability, and long-term reliability.

Frequently Asked Questions (FAQ)

1. What is the purpose of secondary systems in a substation?

Secondary systems protect primary equipment, enable control and monitoring, and ensure safe operation during both normal and fault conditions.

2. Why are DC systems critical in substations?

DC systems ensure protection and control functions remain operational even during AC system failures.

3. When are duplicate DC systems required?

They are typically required for transmission-level substations (220 kV and above) or where high reliability is mandated.

4. What is Group A and Group B protection?

It is a redundancy philosophy where two independent protection systems can each fully protect the same equipment.

5. Why must CT cores not be shared between protection groups?

Sharing CT cores can lead to incorrect measurements, relay mis-operation, or total loss of redundancy.

6. Are circuit breakers duplicated for redundancy?

Usually no. Instead, breakers use dual trip coils and breaker failure protection schemes.

7. Why is cable segregation so important?

It prevents a single fire or mechanical event from disabling both primary and backup protection systems.

8. How does Keentel Engineering address future expansion?

We design spare capacity into panels, cable trenches, and DC systems to support future modifications.

9. What standards guide Keentel’s secondary system designs?

Utility standards, IEC/IEEE practices, NERC reliability principles, and proven industry guidelines.

10. Can Keentel Engineering support retrofit and brownfield substations?

Yes. We specialize in upgrades, retrofits, and life-extension projects for existing substations.

Talk to Keentel Engineering

If you are planning a new substation, upgrading protection systems, or need expert secondary system design support, Keentel Engineering is ready to help.

Contact us to discuss your project requirements.

About the Author:

Sonny Patel P.E. EC

IEEE Senior Member

In 1995, Sandip (Sonny) R. Patel earned his Electrical Engineering degree from the University of Illinois, specializing in Electrical Engineering . But degrees don’t build legacies—action does. For three decades, he’s been shaping the future of engineering, not just as a licensed Professional Engineer across multiple states (Florida, California, New York, West Virginia, and Minnesota), but as a doer. A builder. A leader. Not just an engineer. A Licensed Electrical Contractor in Florida with an Unlimited EC license. Not just an executive. The founder and CEO of KEENTEL LLC—where expertise meets execution. Three decades. Multiple states. Endless impact.

Services

Let's Discuss Your Project

Let's book a call to discuss your electrical engineering project that we can help you with.

About the Author:

Sonny Patel P.E. EC

IEEE Senior Member

In 1995, Sandip (Sonny) R. Patel earned his Electrical Engineering degree from the University of Illinois, specializing in Electrical Engineering . But degrees don’t build legacies—action does. For three decades, he’s been shaping the future of engineering, not just as a licensed Professional Engineer across multiple states (Florida, California, New York, West Virginia, and Minnesota), but as a doer. A builder. A leader. Not just an engineer. A Licensed Electrical Contractor in Florida with an Unlimited EC license. Not just an executive. The founder and CEO of KEENTEL LLC—where expertise meets execution. Three decades. Multiple states. Endless impact.

Leave a Comment

We will get back to you as soon as possible.

Please try again later.